Search

McCloskey International eyes electric avenue to further growth after record-breaking year

Acquired by Metso Outotec in 2019, McCloskey International is part of a group of construction, quarrying, construction and demolition (C&D) and wider recycling industry-suited plant brands that also include McCloskey Environmental, Lippmann, MWS Equipment, and Tesab.

“Last year was a really busy year for us and a record-breaking year, both for McCloskey International and the wider group [of brands] and we are growing again this year,” says Toni Laaksonen, senior vice president of McCloskey International.

“The acquisition of Tesab last year helped grow our revenues. It was a very big thing for us. We have also expanded organically, recruiting more dealers. For example, in Africa, we have grown our dealer networks significantly.

“We have also seen good dealer growth in North America, helping us secure new business.”

Laaksonen says that customers globally are looking for more and more sustainable products, including more electric-powered equipment: “There are certain markets that are very demanding on the electric plant side, such as the European market. We are also seeing this trend in certain American states.

“This demand has led to us introducing new electric-powered solutions, such as electric-power options for our cone crushers. We are also electrifying our heavy-duty jaw crushers, including the J6. Our screeners are already available as dual-power plants.

“We are also looking to grow our business organically through further acquisitions.”

Among McCloskey International’s new machines are the ultra-efficient S190 dual-power portable vibratory screener, and the ST100TVR stacker, the latter said to reach new heights in sustainability, efficiency and fuel savings with its dual power option and lift axle option, allowing it to switch from track mode to radial mode in seconds.

In an eye-catching technical development elsewhere in the group, MWS Equipment has partnered with Metso Outotec's pump and cyclone division to bring new levels of efficiency to its washing equipment.

Booth: Silver Lot, S5411

Simex cold planer gives 80 inches of pure paving power

LiuGong has big hopes in North America for its new 856H-E MAX wheeled loader

The 856H-E MAX is capable of 10 hours of working time for light applications and eight hours for heavy applications. It also features an Intelligent Battery Management System that can be fast charged in 90 minutes.

“The industry is talking about battery electric vehicles at a greater volume than in years past,” said Andrew Ryan, president, LiuGong North America.

“LiuGong is the world’s largest manufacturer of wheeled loaders, so it makes sense for our company to lead the industry in the adoption and application of battery technology.”

The 856H-E MAX has already proven its reliability in the field, with more than 2,000 electric wheeled loaders operating in the world’s toughest conditions as of October 2022, and exponential growth is expected.

Its reliability is reinforced by the IP67-rated wiring harness and waterproof integrated battery package. All of that is backed by a standard five-year or 10,000-hour warranty for the battery, motor, and controller.

LiuGong says the 856H-E MAX thrives in work sites where traditional combustion engines aren’t allowed, or in fixed-site operations where investments in charging infrastructure make sense.

In addition to making work easier, the wheeled loader’s new electric technologies are also environmentally conscious while offering a competitive total cost of ownership. The 856H-E MAX consumes zero fuel, produces zero emissions, and creates significantly lower noise and vibration levels.

The 856H-E MAX features intelligent controls and a human-centric design for a claimed superior operator experience. This includes load-sensing hydraulics, an EAT700 transmission with an electro-proportional valve for fast, smooth shifting, and independent control of the dual-motor drive for maximum hydraulic lift.

The LiuGong Intelligent Auto Digging System automatically carries out repetitive digging cycles to reduce operator fatigue. Its electric control box also improves transmission efficiency compared to conventional machines.

The vehicle was designed around the operator to provide the highest levels of safety, visibility, and comfort, says the Chinese manufacturer. Its cab has full ROPS (roll over) protection and systems are in place to significantly reduce dust and noise contamination.

Booth: Festival Grounds F9205

Liebherr’s record-breaking sales in the US as delivery times improve and demand surges

However, the giant German manufacturer is also seeing strong sales numbers across its international operations, with the US proving a particularly healthy market for the firm.

Kai Friedrich, managing director of Liebherr USA, says that the group has come through the difficult pandemic period stronger than ever before. “We have faced many changes and many challenges.”

Some of the issues the construction machinery firms faced have eased, Friedrich commented, adding: “The worst is behind us, and delivery times are improving. We have seen things easing since the third quarter of 2022.”

For Liebherr USA, 2022 was very healthy and, according to Friedrich: “Our preliminary results suggest 2022 was a record for Liebherr in the US.

“Liebherr is well positioned to meet high demand for cranes and construction machinery. Our commitment to the market goes beyond developing new machines.”

Distribution and customer support remain of key importance for the firm, he said.

Liebherr has been investing heavily in its US operations, spending US$60 million on expanding its headquarters at Newport News in Virginia, adding manufacturing capacity, a new parts and service operation and a new administration block.

The company has further expansion plans in operation and will develop its facility in the Southwest US.

The company is also looking ahead regarding utilising new technologies, Friedrich said. “We see digitalisation as a key opportunity.” Assistance systems and autonomous technology offer major benefits for operators.

“The automated exchange of data between machines is another advance. Processes on construction sites can be optimised to increase production.”

New power systems are another key future development for Liebherr, with the firm keen to develop clean technologies. Liebherr already offers a number of all-electric cranes and drilling machines, with more electric models in development.

Alternative fuels are another important technology, with the company having unveiled its H964 prototype internal combustion engine that runs on hydrogen. This unit has four cylinders, a capacity of 9litres and features direct injection. It will be available for use in a range of construction machines and will be able to cope with a wide array of duties.

Booth F9253

Yanmar Compact Equipment targets rapid growth in North America and Europe

The compact equipment manufacturer’s CEO Giuliano Parodi said that Japan accounted for 54% of its total US$0.7bn turnover in 2015, while the figure for North America was 11%. EMEA (Europe, Middle East and Asia) was 23% of the group’s revenues in 2015.

Fast forward to 2021, and 28% of Yanmar’s total annual turnover of US$1.3bn revenue was coming from Japan, compared with 25% from North America, and 34% from EMEA. The North American share had more than doubled.

By 2027 Yanmar Compact Equipment is targeting annual revenue of US$2.5bn with 41% coming from North America, 30% from EMEA, and just 18% from Japan.

Parodi says that North America accounted for 52. 9% of the global addressable compact equipment market in 2022, compared with 30.5% in EMEA and 8.8% in Japan.

The company has made a number strategic acquisitions to build its business in North America and Europe. It now has a manufacturing presence in Grand Rapids in the US, Crailsheim in Germany, and Saint-Dizier in France, in addition to Chikugo in Japan.

Yanmar Compact Equipment has this week launched a new line of four compact track loaders: TL65RS, TL75VS, TL80VS and TL100VS. These new units enhance Yanmar’s position as a comprehensive compact equipment solutions provider, says the company.

Supply chain headaches remain for the construction equipment sector says AEM

Original equipment manufacturers, OEMs, are struggling with shortages from their suppliers, especially when it comes to processing chips for some of the new smart solution systems being introduced for more efficient machine operation. Delivery and lead times are increasing, said Rod Schrader, AEM chairman, who is also chief executive of Komatsu.

Couple this with a labour shortage felt in most areas of the economy and OEMs are having to be innovative, said Schrader. More shift work and overtime is happening. But instead of OEMs increasing prices once a year, many are inching up their prices three or four times a year.

There must be a revamping of immigration laws and work regulations in the US to ease the shortage of labour, said Kip Eideberg, AEM senior vice president of government and industry. The construction equipment manufacturers must band together to drive the message home to their politicians in Washington.

As the same time, noted Eideberg, the US government should double down on getting better trade deals globally. Around 30% of the sector’s machines are exported, so lower tariffs are needed for maintaining and increasing this figure. Similarly, there needs to be more tax breaks for manufactures to invest more in research and development – essential for US-made and manufactured machines to compete globally.

The AEM report includes the industry’s total and direct contributions to the US economy at the national, state and congressional district levels, as well as economic contributions measured in terms of employment, contribution to GDP, labour income, state and federal tax receipts and more.

Booth: Grand Lobby, GL20401

Doka banks on digitisation, innovation and apps to drive toward net zero emissions

Digitisation of all aspects of onsite working must happen, such as the uptake of building information modelling, the use of apps by Doka and its clients to better control stock and logistics of materials and better analytics of data are increasingly key to better performance for all the players on site.

In particular, Doka has a dedicated department in Austria working on Doka’s ability to comply with Building Information Modelling, BIM, where clients and contractors are using it for a project.

Also, a large part of formwork business is acting as a logistics company, especially when it comes to getting formwork systems to a client’s remote site, noted Michael Kennedy, chief executive of Doka USA which is expanding its operations across the country. The group is working on developing apps that will help locate equipment in real time and help decide where it will be next needed.

It all comes down to innovation, said Zumaglini, and this is where Doka is differentiating itself from its competitors.

Booth: Diamond Lot D2001

Cummins gets ready for a zero-emission future and an alternative power present

Cummins’ off-highway business executive director was speaking after the recent launch of Accelera by Cummins, a new brand for the company’s New Power business unit.

Accelera by Cummins provides a diverse portfolio of zero-emissions solutions for many of the world’s most vital industries empowering customers to accelerate their transition to a sustainable future.

“As an industry, our next big challenge is around carbon emissions. Cummins embraces this opportunity and always tries to bring as low emissions products to the marketplace as we can.

“With the complexity and the variation of the applications in the off-highway world, it requires us to focus on two main areas: advanced and internal combustion engine technology, with further enhancements to performance and compatibility with cleaner fuels, and zero-emissions solutions, like hydrogen fuel cells, battery technology and electrolysers.

“We are technology leaders today and will be technology leaders tomorrow.”

Cummins reported strong performance for its fourth quarter and full-year 2022. Revenues for the fourth quarter were US$7.8bn. Excluding Meritor, the acquisition of which was completed on 3 August 2022, revenues were $6.6bn, 13% higher than the same quarter in 2021.

Excluding Meritor, sales in North America increased by 25%, and international revenues decreased by 1% compared to the fourth quarter of 2021. But strong demand across all global markets was offset by a slowdown in China and Russia, where operations have been suspended indefinitely.

South Hall, Booth S84615

It's Day 2 at CONEXPO-CON/AGG 2023

Keep moving with Ammann’s mobile ACM Prime asphalt plant

The Ammann ACM Prime continuous asphalt mixing plant is the ultimate in mobility. Ideal for smaller contracts, it moves whenever and wherever you need to go. Everything is on wheels. Designed specifically for the North American market, the ACM Prime plant has a production capacity of 270-360tonnes/hour. The whole unit fits on two, two-axle trailers and remains on them upon arrival and during operation. To relocate the plant, the trailers are simply attached to a truck tractor unit and moved. Accessories such as tanks, RAP feeders, self-erecting storage silos and the control house are also on wheels, unlike previous models, where many of these elements were static.

Product Information Link

Ammann knows how to conquer dirty and challenging jobsites

Some jobs are dirty and challenging with poor access and unstable ground conditions. Use Ammann’s remotely controlled ARR 1575 trench roller to win the day. The ARR 1575 is an articulated trench roller that provides perfect ground contact and optimal compaction. The machine and its padfoot drum provide good quality results, no matter how difficult or ugly the job looks. Ammann has designed the ARR 1575 to work in the poorest of soils. It can prevent the need for soil removal and replacement, helping to boost your profitability on site significantly. Two steering cylinders help make the ARR 1575 responsive and precise, while the oscillation feature provides excellent stability on uneven surface of a ditch, says Ammann.

Product Information Link

Ammann compaction plates for a fast and efficient finish

There are Ammann plate compactors for every situation, from a lightweight 119lbs machine to a much heavier 1818lbs unit, with many models in between. All Ammann plates are easy to operate, making them ideal for rental fleets. They also are versatile, safe, and efficient. The APF 15/50, for instance, combines Ammann’s powerful and technologically-advanced exciter system with industry-leading low hand-arm vibration (HAV) levels. Not only are these machines comfortable and safe to operate, their advanced exciter units are maintenance free. Add punch to your jobsite with these best-in-class plate compactors.

Product Information Link

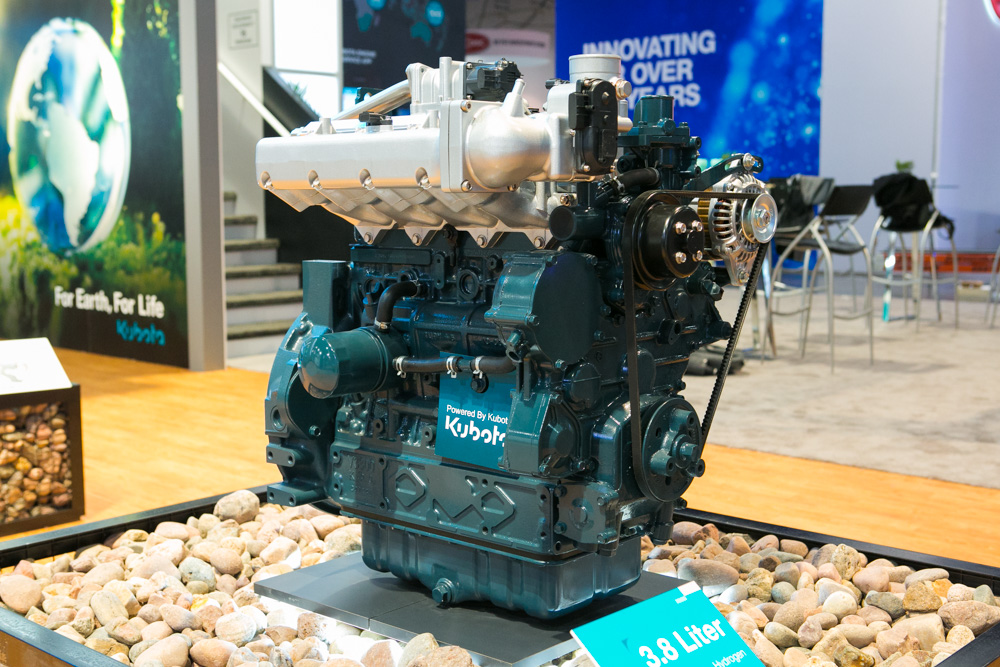

Hydrogen power for Kubota’s new range of clean engine options

The firm also says that it offers diesel engines able to run on gas to liquid (GTL) and hydrotreated vegetable oil (HVO) fuels complying with the appropriate quality standards, enabling a reduction in CO2 emissions of up to 90% with no engine modifications needed.

Kubota believes that a hybrid system combining engine and electrical power is an effective solution for reducing CO2 from industrial engines, power units which require high output and high load levels.

The D1803 P1 Hybrid engine is compact and highly robust with an integrated motor generator embedded within the flywheel housing. With the P1 Hybrid engine, the motor only assists for the brief periods in which high output is required.

The switch between engine and electric motor drive will be offered with the D1105 P2 Hybrid engine, which offers a rated output of 18.5kW at 3000 rpm. This D1105 P2 Hybrid model also offers the ability to transition between diesel engine drive and electric motor drive while in operation. The advantage here is that in areas where emissions or noise are a concern, the engine can be stopped and switched to the electric motor. Production of the new D1105 P2 Hybrid is scheduled to start in 2025.

In another development, Kubota says that its V3307 Micro-Hybrid engine will be go into production later this year, offering a straightforward design with three main components: a DC converter, a lithium-ion battery and a motor generator attached to the existing engine model. And, because Kubota’s electronically-controlled diesel engine is a three-cylinder diesel engine with a displacement of 0.898litres and an output of 18.5kW at a rated speed of 3600 rpm, black smoke emissions have been reduced to an invisible level during startup, acceleration and sudden load … all as a result of the new TVCR combustion system.

Booth S84415

Bay Shore launches Drill Sergeant X excavator attachment for greater reach and swing

The DSX can be used in a range of applications from core drilling to signposts, pedestrian bridges, overpass bridges, light poles and street lighting.

According to Josh Keough, southeast US sales manager for Bay Shore Systems, the new system will be available in the US as well as India, Russia, Australia and Mexico (where it has two representatives).

Bay Shore Systems started in 1978 as a family-owned manufacturer of foundation drilling equipment. Originally based in the San Francisco Bay Area, the relocated to Rathdrum, Idaho, in 1996. It also has a manufacturing and service facility in London, Kentucky.

RubbleCrusher positions itself for US boom in crushing and demolition waste recycling

According to McLanahan, RubbleCrusher was founded with a focus on supporting the “zero waste” approach to the construction and demolition recycling industry. The machines, which are made in Leicestershire, England, are aimed at “small-to-medium-sized crushing and recycling projects that help contribute to a circular economy.”

Bought in June of last year, RubbleCrusher is one of McLanahan’s family of companies, which also includes Eagle Iron Works, Anaconda, and its latest acquisition, Diefenbach (an Italian filtration, water and tailings management firm).

Liam Holland, RubbleCrusher’s business line director, says the firm, formerly a brand owned and operated by CMB International, is excited about its commercial opportunities in the US, where it is in the process of expanding its dealer network.

“RubbleCrusher is an answer to the increasing pressure that governments around the world are putting on construction companies to target zero waste on their sites,” he says. Its compact crushers can be mounted on wheels, tracks or a skid, and pulled behind a truck.

“We see that it is not just the large-scale projects that need to reduce the amount of waste on-site, many small-to-medium-sized projects need a solution too. That was the inspiration behind the creation of RubbleCrusher.”

RubbleCrusher’s pull-behind portable crusher, RC150V, was, says Holland, developed for small-to-medium-sized recycling projects where the cost and size of larger, traditional machinery would have made recycling impossible.

The RC150V can be hauled by any full-size pick-up truck, simplifying set-up at any operation. The RC150V unit weighs just under 3.54 tonnes and enables to operator to recycle C&D waste materials for use on-site, without having to pay to remove materials or bring in new aggregate for jobs.

The RC150T offers the same features as the RC150V but is mounted on tracks, making mobility on-site possible by remote control. These tracks also allow it to be moved across roads, pavements, and driveways without causing surface damage.

Both units feature a hydraulically driven jaw that gives users the option to run the crusher forwards or backwards. The reverse function allows for clearing any blockages as well as processing sticky asphalt material. The machines are equipped with a 40-litre fuel tank that allows for a minimum of eight hours of crushing time. The RC150V and RC150T can both process up to 300 tonnes of material per day, depending on feed material and output setting.

“RubbleCrusher plants can be used across various sectors, such as demolition, construction, and landscape gardening. They remove the need to take construction and demolition waste away from site and eliminate the cost of buying in aggregates for the sites where they work,” says Holland. “These simple, easy-to-use machines can be operated by one person, transported by a 4x4 pick-up, and set up to crush within minutes.”

Booth: McLanahan C31372, RubbleCrusher S5276

Ammann’s new continuous asphalt plant innovation for North America is 100% mobile

The firm is also introducing its proven ACM Prime Asphalt-Mixing Plant to North America, which is primarily built in the US and offers the benefits of a high-capacity plant in a fully mobile package.

The ACM Prime Asphalt-Mixing Plant fits on two, two-axle trailers and remains on them upon arrival and during operation. To relocate the plant, the trailers are simply attached to trucks and moved.

The new ACM Prime is a continuous plant that is 100% mobile. Accessories such as tanks, RAP feeders, self-erecting storage silos and the control house are also on wheels. With previous models, some of these elements were stationary.

Ammann’s business development manager Carlo Machado said, “We decided to move asphalt plants to the US and will be manufacturing here. We are working on developing the supply chain.”

John Elliott has been hired as president, North American Asphalt Plants for Ammann and explained, “The US is a continuous asphalt plant market. Ammann has got a lot of sophisticated technology applicable. We recognise this as an opportunity for Ammann and we are building a team to capitalise on it.”

Elliott said that the new, large-capacity plant will benefit from Ammann’s sophisticated technology and will feature a counterflow drum mixer with a 50% recycling capability.

Meanwhile, the cost of the compact ACM Prime Asphalt-Mixing Plant is less than a conventional stationary plant, making it easier for small businesses to enter the market. The firm says that the plant can be ready to work quickly. It arrives assembled, and plug-in components make set-up extremely fast.

While the ACM Prime is highly mobile, it produces high-quality mix. The plant has successfully manufactured mix for airport runways, where quality is of the utmost importance.

Production capacity is 161tonnes/hour with 5% moisture. Mixing times are adjustable, based on the recipe and desired output. The plant can utilise RAP, produce warm mix, and incorporate filler, fibres and other additives.

The Ammann as1 Control System helps improve quality while reducing material waste and energy consumption. A proven, reliable and robust fieldbus system is included.

Fuel efficiency is another benefit. Heat exchange is optimised between hot gases generated by the burner flame and aggregates. Enclosed gaskets between the dryer and chamber are well insulated. Air pressure is controlled inside the drum and burner, and dryer and burner settings are precise to minimise fuel burn.

Booth S5455

CONEXPO/CON-AGG opens doors to biggest-ever staging of the exhibition