Search

Connect with Indeco’s Indeconnect

Indeconnect, using the Internet of Things and 4G technology, runs through sensors mounted on the various attachments. The cloud-based web platform is accessible from a mobile app or a PC.

The system allows a machine operator or fleet manager to consult the data transmitted in real time by each installed device, to see information such as hours of work done, working position in space, hydraulic oil temperature, ambient temperature and GPS location.

According to Indeco, an Italian manufacturer of hydraulic breakers, this makes it possible to monitor productivity, control the operation of equipment, increase safety, predict and plan maintenance, and manage rented equipment.

Electric concrete slipformer revolution from GOMACO

Keogh said that the battery will power the machine for eight hours when laying kerb in a straight line, although he added that this may drop to around six hours when working around curves due to the extra power needed for the steering system. Recharging the 48V DC lithium-ion battery pack takes around 8-10 hours from a conventional 220V supply, although a two-hour fast charger is an optional feature.

The first unit has been equipped with a Topcon machine control package, although Keogh said that customers can order technology from Leica Geosystems or Trimble if they prefer. He said that that the 3D machine control system is just for steering, as the level of the kerb being laid follows the level of the road.

The machine is operated using a radio remote control unit that features GOMACO’s proven G+ control system. Features include rotary-sensored slew drive steering on the front assembly for tight turning, smooth paving and ease of control.

The machine can pour a 610mm radius, has a paving speed of up to 12.2m/min and an auxiliary speed of 28.3m/min for site mobility. Different mold configurations are offered, allowing a 305mm wide by 356mm high section. The mold can be mounted on either side of the machine, while the hopper and mold are adjustable up to 381mm.

Leg elevation is controlled by three hydraulic cylinders, each with a stroke of 254mm as well as an additional 127mm of manual adjustment.

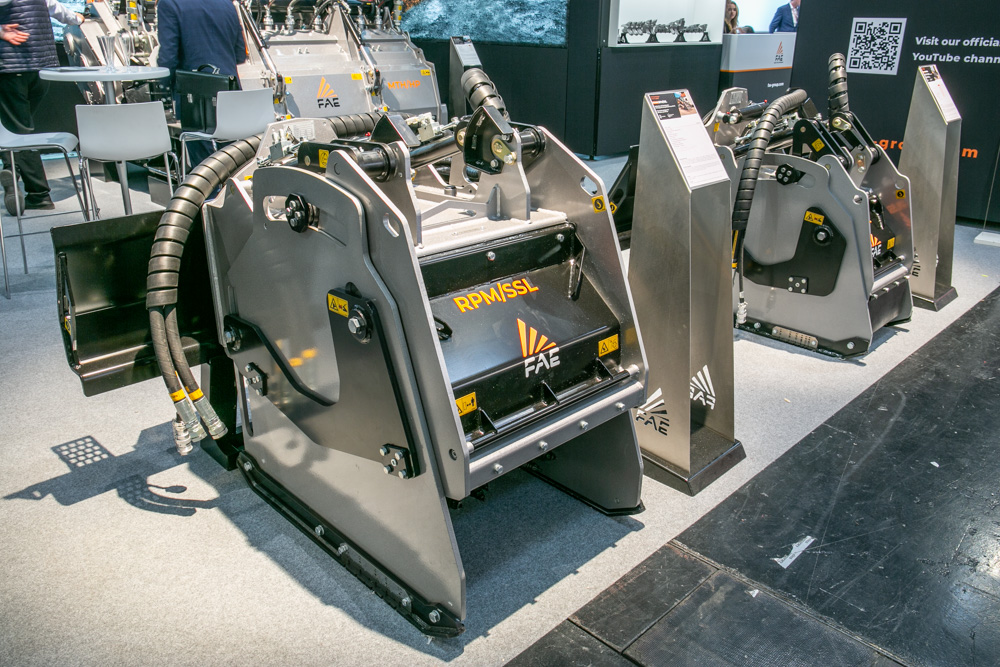

FAE enters the road planing market

FAE is gearing up for production for the 1,650mm-wide machine, specifically made for skid steer loaders. With its 600mm-wide planing width, it is ideal for municipalities that need to carry out small repaving projects along urban roads. It is also efficient for repairing the hard shoulders of major roads and motorways.

Standard equipment includes a mechanical tilt system of 8°, independent hydraulic skids control and a maximum working depth of 250mm. The RPM/SSL weighs in around 1,170kg.

Into the Vortex with CM Labs

The new releases from the Canadian firm all run on the immersive Vortex Advantage and the entry-level motion-enabled Vortex Edge Max. Both simulators are deploying CM Labs’ full catalogue of earthmoving and lifting equipment, including the recent release of their boom truck simulation training pack.

In addition, attendees are experiencing CM Labs’ newly expanded excavator simulator training pack, which includes tiltrotator and jackhammer attachments. This training pack integrates with the Trimble Earthworks Grade Control Platform, now available with the dozer and motor grader training solutions.

During operator training sessions, all information is captured by the simulator and pushed to an Instructor Operating Station (IOS). The IOS supports trainers with objective reporting on key metrics related to safety violations and efficiency, which provides valuable insight into the operator’s true capabilities.

This insight is possible due to the high fidelity of CM Labs’ training solutions, powered by the company’s exclusive Smart Training Technology.

Comprised of proprietary and patented algorithms, Smart Training Technology results in training that’s based on real data and real machines, delivering the most transferable operator skills anywhere, outside the real equipment.

CM Labs’ clients include OETIO, IUOE, Kiewit, Liebherr, Mammoet, Manitowoc, NASA, and over 100 other world-class companies, OEMs, equipment operators, and trades training organisations.

Meiller brings to market three-way tippers for all weight classes

Dubbed Trigenius, the range is a radical redesign of its predecessors. In every weight class, from the light D202 tipper body for 3.5tonne vehicles to the large D428 for four-axle vehicles with an overall weight of 41tonnes, functionality, operation and handling are the same.

The modular design and the increased use of bolted connections facilitate numerous individual adaptations to meet varied customer requirements, meaning numerous options can be retrofitted at a later stage.

All Trigenius three-way tippers are based on a modular system and have a new, uniform operating concept across all series. Ergonomically designed components shorten operating cycles and make for efficient operation and handling, says the company. The design of the Trigenius reduces weight, while the use of high-strength steel increases loading capacity.

Strategic cooperation with all European commercial vehicle manufacturers enables harmonisation between the vehicle chassis and the Meiller superstructure. A close exchange between Meiller and truck manufacturers enables the tipper maker to respond rapidly to new market requirements.

Matec presents ‘Twin Freccia Rossa’ prototype of world’s biggest filter press

The first full-production, 50m-long, up to 380-plate and 600 t/h machine is set to be snapped up by a Turkish iron ore mining customer. The Italian company says its innovative machine combines the efficiency of two machines into a single product with exceptional performance, offering faster sludge feeding and cake discharge time.

The patented ‘Twin Freccia Rossa’ is said to reduce customers’ operating costs and allows production to continue during maintenance times. Featuring a single conveyor belt, feeding point, silo decanter, supporting structure, homogeniser tank, high-pressure 10-16-21-30-bar technology, a protective shell for the oleodynamic unit and piston, and four-point cloth washing, the cutting-edge filter press can be equipped with 25 to 50mm standard or membrane plates.

“All our customers are asking us for two filter presses in one machine,” said Matec Industries CEO, Matteo Goich. “We started work on Twin Freccia Rossa around a year ago and the customer who will operate the first full-sized version of this new filter press already has one of our washing plants and six of our filter presses.”

Seeing is believing: Peri’s XR Ecosystem

The system, which is still in development, visualises formwork and scaffolding projects in 3D and takes the industry to the next level, says Peri. It optimises communication, safety, and efficiency on the construction site.

Ono-site workers, using an app on their phone or tablet, request information from another employee sitting in a central office where they have access to assembly knowledge.

The onsite workers the pan their tablet’s camera around on site, in the area where the formwork will be assembled.

Meanwhile, the office worker, seeing this image and wearing their 3D goggles, can assemble the required system. Simultaneously, back on site, the team can see this being done on their screen. They then have all they need to finish the job.

Using augmented and virtual reality, 3D designs can be walked through virtually … or projected into the physical environment. Due to the different visualisation options, the respective models are optimally integrated into the planning and construction process.

Importantly, for clients, the XR Ecosystem allows integration of 3D and BIM models (building information modelling) in the planning and construction process, thanks to different visualisation options.

Peri also points out that the system could be especially useful in remote areas where in-person assistance is not immediately available. It also could be used to train people.

CIFA unveils fully automated shotcrete pump for underground construction

This is made possible by the inclusion of a laser scanning device on the machine, which allows the operator to take measurements of the tunnel before and after application, thus providing data about the average thickness of the layer of sprayed concrete being applied.

Davide Cipolla, CIFA’s CEO, explained that the new underground range is inspired by nature, which is why the models are named after animals with similar physical or behavioural characteristics. ‘Inspired by nature’, he says, refers to more than just the names of machines, it also describes the company’s goals and aspirations when designing the range.

“We aim to make these CIFA machines as eco-friendly as possible, respectful of the environment and people, and able to transform the notoriously unhealthy underground construction site into a sustainable eco-system,” he said.

Manufacturers of tunnelling machinery, he added, need to work together to create a sustainable construction site in what is a challenging environment – an enclosed space with poor ventilation.

“We need to design intelligent machines, harnessing data to increase efficiency, using electricity to cut emissions and technology to simplify the work of operators.

“The first step towards a sustainable business model is to create intelligent machines, designed to optimise the consumption of resources. This forms part of a holistic approach that examines the overall impact of every operation, and not just the performance of the individual machine.

All the data collected by Mamba can be used in the future to determine where to spray concrete and how much to apply at a time, creating a digital model of the tunnel in line with the Building Information Modelling (BIM) method.

In addition to Mamba, the range consists of several other shotcrete models (Elk, Dingo, Rhino and Mantis) and concrete mixers (Coguaro and Myria), in varying sizes and with different features in line with their applications. All the models can be customised to meet the needs of particular projects.

Piling rig control system from Trimble

The Trimble Groundworks package is a 3D machine control system said to improve efficiency and reduce downtime with stakeless navigation, productivity and quality monitoring, and office-to-field connectivity.

The integration of Trimble software in the office and Trimble Groundworks in the field can increase the efficiency and productivity of piling operations, wirelessly syncing data to reduce site visits and provide a single data source.

Trimble Groundworks allows operators to create an in-field design for piling and create piling reports. To reduce blind spots, administrators can set avoidance zones in the design file. With stakeless workflows, Trimble Groundworks is said to reduce the need for surveyors to be near the machine, making job sites safer.

For an ABI Mobilram-System or DELMAG drill rig, the option to install a Trimble Groundworks base kit provides mounting hardware, brackets and an integrated wiring harness. Having the system installed in the factory can reduce cost and complexity for the customer.

"Trimble enables our customers to map the entire construction process from planning to quality management. On construction sites, for example, the pile grid does not have to be measured in place," said Tobias Schmidt, head of control engineering electrics at ABI.

"A significant advantage of the Trimble Ready solution is the direct communication with the ABI control system, so that the sensor technology available on the machines can be integrated. The necessary mounting options on the machine are already prepared. This significantly reduces the costs required to equip a system from Trimble."

For the Junttan piling equipment, the technology is said to allow more efficient and safer working, along with stakeless workflows and 3D machine control. The system helps optimise productivity by allowing operations during the day or night. The 2D or 3D guidance technology allows accurate piling depth and direction, reducing driving time for each pile, cutting fuel consumption.

"Junttan strongly believes in the benefits of digitalisation in the piling construction field," said Karoliina Pesola, head of digital and measuring solutions, Junttan. "Trimble Groundworks connected to Junttan's machine control system PCD will provide a new dimension to our customers' piling experience."

Infrastructure funding secured for Australia’s Victoria and Queensland States

SmartSheetPile from ArcelorMittal provides data in real time

The goal of the next-generation sheet piling solution is to enable preventative maintenance and extended project lifetime. The solution will be a game-changer for critical infrastructure and construction projects, such as quay walls, bridges or flood protection walls, the company says.

It says the solution makes infrastructure installations safer and more cost-effective. With this technology, sensors built into the sheet pile collect high quality and precise data that can be analysed and used for informed decision making.

Relevant information on the structural condition of the sheet pile wall – for example, regarding corrosion, deformation or inclination – can be displayed on online monitoring dashboards or even fed into the asset’s digital twin. The SmartSheetPile is able to identify accidental or weather-related damage and sound an alarm in the event of a critical incident. Potential flooding could be prevented, for example.

“Monitoring infrastructure in real time will enable early warning of potential failure risks so that preventative measures can be taken,” said Tapas Rajderkar, chief marketing officer at ArcelorMittal Europe – Long Products. “This reduces maintenance costs, prevents failures and increases the life of the structure.

“We already offer such tailor-made solutions today. Beyond that we are developing SmartSheetPile further for a standardised industrial launch in the next few years,” added Rajderkar.

In addition, data collected provides insights for designers, which can be used in the development of new optimised models – with potential positive effects on material consumption and carbon footprint.

RM unveils H50X hybrid screen

As a hybrid variant, RM says the machine can be operated electrically to notch up zero emissions. It adds that the screen delivers impressive modularity and versatility.

“It’s a whole new conception of doing a scalper,” said Gerald Hanisch, founder and CEO of the Austrian-headquartered RM Group. “It is not only electrified, it has all kinds of features – the mobility, the versatility, the simplicity and the energy.”

RM says that both the RM5H50X hybrid screen and the RM J110 jaw crusher – which will make its debut at Conexpo in March 2023 – have incorporated countless ideas and customer requests to redefine the application options of processing equipment.

RM says the use of a hybrid machine brings a 25% reduction in fuel costs compared to a diesel-direct crusher or a hydraulic screen, while combining them into one machine train increases the savings even further.

It adds that, when a diesel-direct crusher drives the new RM hybrid screen, the customer saves up to 33% on fuel. In combination with an RM hybrid crusher, which drives the RM hybrid screen, the savings potential reaches up to 50%.

In addition, if only one engine is running because the crusher is driving the screen, the customer only has to refuel and service one engine, effectively saving fuel, time and money.

Hanisch added: “We have been electrifying our plants for decades, and consequently have the necessary know-how. Now the time is ripe for us to fulfil the needs of customers with our product-ready solutions. The lowest possible fuel consumption and smallest carbon footprint are the order of the day for our customers to be successful.”

Vögele’s new Dash 5 paver is ready for the digital future

Innovative, easy-to-use, sustainable, modular, transportable … the Super 1900-5i is set up to help you make money.

Komatsu aims to be completely carbon neutral by 2050

According to Komatsu Europe’s chief operating officer Goksel Guner, the group will also “increase the rate of renewable energy used to 50%”.

The world’s second-biggest manufacturer of construction equipment says that it will bring the same approach to its supply chain.

“Komatsu will deploy the relevant technologies at material suppliers and other partners to help them also achieve carbon neutrality in their operations,” says the company, and it will be “adopting a two-pronged approach toward this drastic reduction.

“With about 90% of the total CO₂ being emitted by products in use, the first prong is to increase the equipment’s work and fuel efficiency, and to transition from diesel and other internal combustion engines to cleaner power sources, including hybrid and electric engines and fuel cells.”

The second prong will centre around Komatsu’s ‘Smart Construction’ project, which the company describes as “the improvement of processes.

“CO₂ emissions will be lowered by helping to optimise customers’ workplace operations and processes, to reduce the amount of equipment needed along with actual operating hours.”

Following the well-established ‘work smarter, not harder’ principle, Komatsu will also be pushing its ability to re-manufacture and re-use components, seeking “carbon neutrality initiatives at production bases (and) energy conservation ideas.”

Renewable energy generated in-house and bought from the grid will play a big part, too.

Accurate asphalt paver control from Trimble

The system can be used to steer Vögele asphalt pavers automatically and also controls the screed width. The steering and screed functions follow a 3D design, which is programmed into the system. According to Trimble, this is the most advanced 3D paving technology the company has developed so far.

Providing auto steering and screed control allows for higher-quality paving while also meeting high accuracy requirements and boosting productivity. As the system controls these functions, the operator has more of a machine supervisory role and will be less fatigued than when using conventional systems.

Other improvements from the new system include waste reduction and improved jobsite sustainability.

The system also allows users to estimate material quantities more accurately before work starts, as well as consuming less asphalt during the paving process, delivering major cost benefits.

Both Trimble WorksOS Software and Trimble WorksManager Software are supported by Trimble Roadworks version 2.10 on compatible pavers, increasing connectivity between the field and the office and making it easy to share design files, generate productivity reports, analyse elevations and more.

"Asphalt pavers can be difficult to steer effectively," said Kevin Garcia, general manager for Trimble Civil Specialty Solutions. "Horizontal Steering Control and screed width control makes it easier for operators to deliver a higher quality surface and get up to speed quickly, and makes the job easier and less exhausting for operators."

More than 400,000 machines join new CECE construction equipment ‘uptime’ utilisation tracker

More than 400,000 earthmoving machines will be monitored and nearly all of the main manufacturers are taking part, said CECE secretary-general Riccardo Viaggi.

The test phase of the project is over and Viaggi is confident that the project now has the “critical mass” necessary to move forward.

“Telematics data has become a key factor for OEMs (original equipment manufacturers) in analysing construction activity and performance,” said CECE, especially “in times of crisis when sales are slowing down.”

Viaggi now plans for the tracker to “slowly and steadily expand, with improved granularity” in terms of ever-better detail.

The reports will only be available to those who take part, and the data collected will not be shared with the outside world.

“By pulling their telematics data together within CECE, the participating OEMs get the monthly Uptime Tracker with industry-wide utilisation rates in anonymous and aggregated format,” said CECE.

“With regards to competition law, the critical mass of participating OEMs and the size of the connected fleet constitute a guarantee that no individual company data can be derived from the data output. The same argument goes for data protection and privacy.”

“I am convinced that the new CECE Uptime Tracker closes a gap in the market intelligence services we provide our member companies, and we are proud to be the first to establish such a project at the industry association level,” Viaggi added.

The association is also continuing to develop its involvement with the EU’s InfraROB highway safety initiative. This “aims to reduce workers’ exposure to live traffic and road construction machines, to increase the availability of the transport network, to reduce the cost of repetitive tasks, and to increase the safety of road users by promoting significant advances in automating, robotising and modularising the construction, upgrade and maintenance of the road infrastructure.”

CECE hopes that work being done could be a game-changer, not least because “there are many health and safety risks when it comes to using and working on roads.

“InfraROB will focus on automating, robotising and modularising road construction and maintenance work.” It is focusing on “autonomous robotised systems and machinery to carry out line marking, repaving, and the repair of cracks and potholes.

“It will also develop collaborative robotised safety systems for construction workers and road users … the project further aims to integrate pavement management system and traffic management system solutions for a holistic, unified management of road infrastructure and live traffic.”

CECE is an association of trade associations. It represents the interests of national construction equipment manufacturer associations across Europe, looking after the interests of around 1,200 companies and 300,000 workers.

It has added three new members this month, its first expansion in many years. They are MGF, the machinery importers’ association of Norway; Soima, a Portuguese tower crane manufacturer; and Trackunit, a Danish data telematics company.