Slovakian highway deal for Budimex

The future is green: Don’t get left behind says bauma 2022

Think electric, smart tech, and road re-surfacing with no new material needed. The future work site is going to be a greener, quieter, and nicer place to be.

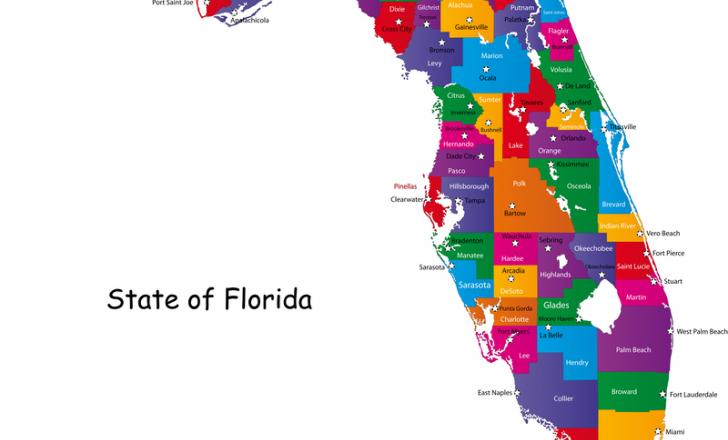

Emergency repairs for Florida infrastructure

E+ Screed Heating paves the way

Hanwha on the Pedemontana Veneta

UK road service contract awarded to Atkins

Buoyant bauma booms

Haul truck developments

REBLOC barriers for Antwerp’s Oosterweel Link

Cambodian expressway proves popular with drivers

John Deere ploughs significant resources into electric future

To demonstrate strides made toward low- and near-zero carbon propulsion systems, the company is showcasing a suite of electric systems, including batteries, drives and converters.

A key talking point, explained Collin Krantz, John Deere Power Systems’ OEM implementation manager, is the Kreisel Battery Pack 63 (KBP63), which utilises Kreisel Electric’s patented immersion cooling technology for efficient thermal management.

This ensures that all cells are stressed equally, prolonging battery life while meeting high safety standards. The technology offers a low temperature spread of <1°C throughout the module, thus increasing service life and reliability.

“The modules in the battery pack are interchangeable, allowing the battery to serve multiple applications with just one platform solution,” said Krantz. “The same module is adaptable for use in the automotive and commercial vehicle, off-highway, transportation and marine markets. It can be connected in parallel as well as in series (400V or 800V). This offers high flexibility in combination with different possible installation positions.”

In addition, the company is showcasing a series of inverters based on a modular concept that supports single or dual configurations with a variety of other hardware options. The high-voltage, high-power, liquid-cooled modules are designed to work at maximum efficiency with complete monitoring capabilities.

The common control architecture enables advanced software features for control under all conditions and supports a variety of different motor types.

Doka lists CO2 emissions data for its products

Doka has pledged that it will be climate-neutral by 2040 as it addresses one of the most pressing issues in the global construction industry. By focusing on decarbonisation and the circular economy, the company says it has already made an important first step towards achieving this goal.

Last summer, Doka introduced the Product Carbon Footprint to help customers make more environmentally responsible purchasing decisions, explained Robert Hauser, the company’s chief executive.

"Sustainability and digitalisation are two of the most powerful market influences and important pillars of our global growth strategy,” he said. “With the calculation of the Product Carbon Footprint, we empower our sector to make environmentally conscious product selection decisions.”

The Product Carbon Footprint details each product’s CO2 emissions. The company reviewed the composition and raw material requirements for each item’s manufacturing, plus delivery methods to the worldwide distribution centres and branch offices, repair and cleaning processes, as well as end-of-life recycling. This cradle-to-grave approach allows Doka to detail each product's carbon footprint over its entire life-cycle.

For example, the Doka floor prop Eurex 20 top 300 generates 38kg CO2-equvalent, while the Doka floor prop Eurex LW 300 accounts for 27kg CO2-eq. Thanks to high-strength steel and state-of-the-art production, the latter weighs significantly less than standard tubular steel props, delivers the same performance and service life, but with fewer CO2 emissions.

Sinoboom’s SPA33HJ hybrid spider lift makes European debut

The model was developed in collaboration with spider lift specialist manufacturer, Falcon Lifts. The arrival of the SPA33HJ in Europe follows the conclusion of a wide-ranging partnership agreement between the two companies.

The partnership follows extensive research and cooperation during the past 12 months, during which time Sinoboom launched own-branded spider lifts built by Falcon into the Chinese market.

“The agreement is part of Sinoboom’s commitment to providing its global customer base with a complete range of MEWPs,” said Sinoboom CEO, Susan Xu.

“We expect the combination of Falcon’s high-quality design with Sinoboom’s worldwide customer base and after-sales support to make this a great success.”

Zoomlion R220-10S and R90-5RE tower cranes debut in Europe

The R220-10S is a star flat-head tower crane based around Zoomlion’s future-oriented digital, green, and high-performance technology, in combination with the demands of the European market.

The crane was jointly developed by the Chinese and German teams of Zoomlion Construction Hoisting Machinery.

As a tailor-made product for the European market, the R220-10S can provide 15 different arm length options to meet the demands of various working conditions.

It is equipped with intelligent functions such as one-button super-lifting, on-load speed, zero-speed hovering and one-button debugging as standard features.

Zoomlion says it has used a narrow boom structure and rotary mechanisms to make the unit easier to transport.

The R90-5RE is a flat-head tower crane fitted with a round-tenon tower body for lower wind resistance and easier assembly and disassembly. It will be a popular option for small housing construction projects, says the manufacturer.

MTG launches digital safety system

Spain-based MTG produces a range of teeth systems for use with excavator and wheeled loader buckets in quarries, construction sites and mines.

The company says the GET Detection Series provides its customers with increased safety by preventing a crusher – for example, being used in a quarry – from being damaged if a GET (ground engagement tool such as excavator bucket teeth) becomes detached.

“Based on extensive laboratory bench testing and field tests, we can state that MTG’s solution detects a possible GET detachment in less than three seconds, with a very high level of reliability, preventing a subsequent fall into the crusher,” the company says.

The system uses visual and sound alerts via the display screen on a tablet in the cab, to alert excavator drivers to any teeth detachments from the bucket.

The GET Detection series includes a suite of devices compatible with MTG’s Terra cast lips, Twinmet and new Veemet tooth systems as well as Promet shrouds. The GET design of these product families enables the addition of sensors and activators to allow digital monitoring of the entire cast lip configuration.

The signals emitted by the GET sensors are transmitted via antennas and processed by an electronic control unit. A tablet in the machine’s cabin displays the GET’s live status and alerts the operator in the event of an incident.

GET Detection has especially been developed for hydraulic excavators with an operating weight of more than 250tonnes and is so far available in Australia, Europe, and the USA. More markets will follow shortly, and new GET Systems will be compatible with the GET Detection System.

Also new from MTG is the Comet fully hammerless solution for small construction machines. This new tooth system has been especially developed for digging applications of excavators <15tonnes, mini loaders, and backhoe loaders.

Available in sizes 5, 8, 10 and 15, the new Comet’s features are designed to give users higher productivity, maximum reliability and a longer operational life.

The third new launch from MTG is the Veemet tooth system suitable for wheeled loaders and excavators between 20-150tonnes operating in quarries, construction sites and small mines.

John Deere’s strategic investments in alternative fuel solutions

This includes renewable fuel solutions that can address customers’ pain points and give them a competitive edge in the off-highway market.

Collin Krantz, John Deere Power Systems OEM implementation manager, said the company is committed to bringing “the most advanced, affordable and effective renewable fuel solutions” to its customers, so they know the equipment they are using is setting them up for future success.

“Petroleum-based fuels have been the industry standard for years, primarily due to the lack of acceptable, cost-effective and reliable alternatives,” said Krantz.

“However, with growing interest in sustainable energy, renewable fuels are becoming more widely adopted and readily available. Within the variety of available renewable fuels, we believe biodiesel and renewable diesel fuel will integrate most effectively within the heavy equipment industry.”

The company has made significant progress in testing engine compatibility with renewable diesel fuel such as hydrogenated vegetable oil (HVO), which is a biofuel made from hydrocracking or hydrogenation of vegetable oil.

Ethanol, a renewable fuel made from corn and other plant materials, is another option of interest. Ethanol is widely used in the industry, with the most common blend being E10 (10% ethanol, 90% gasoline). The use of biofuels such as ethanol, biodiesel and renewable diesel, said Krantz, has contributed to significant reductions in carbon emissions for existing vehicles in the past decade.

Biodiesel is a renewable, oxygenated fuel made from a variety of agricultural resources such as soybeans or rapeseeds. It contains no petroleum but can be blended at any level with petroleum diesel to create a biodiesel blend. As a renewable, domestic energy source, biodiesel can help reduce dependence on petroleum imports.

To support this goal of providing differentiated powertrain solutions, John Deere has made an equity investment in ClearFlame Engine Technologies, a growing start-up dedicated to the development of clean engine technology.

ClearFlame’s solutions enable low-carbon fuels such as ethanol to be easily integrated into compression ignition engines, offering a more sustainable solution without compromising engine performance.

“The John Deere investment is in line with its strategic vision to accelerate and lead the industry in low- and near-zero-carbon powertrain technology,” concluded Krantz.

Kohler gears up for sustainable power growth in 150th year

The company has set out its new strategy toward a more sustainable future, revealing its long-term plan and next steps to transform the group from a power producer to an energy supplier.

The company says the unveiling of this new strategy comes at a momentous time for the engine industry.

Kohler’s strategy incorporates alternative fuels, electrification and hybridisation to reduce engine size or achieve zero emissions during operation, together with introducing hydrogen as a potential ‘green’ fuel.

The manufacturer recently acquired electric vehicle and hybrid applications company Curtis. Kohler says the acquisition expands and diversifies its product portfolio, leveraging Curtis’ expertise in electrification, and solidifying Kohler’s commitment to hybrid and electrified solutions.

Kohler’s road map toward electrification has 2025 as its first goal. The company says its vision is to develop sustainable and technically sound EV system solutions to increase the performance of internal combustion engines by placing full electric solutions alongside them.

Kohler is updating its K-HEM series hybrid unit for the combined electric and mechanical power solution. The range will move from the booster hybrid version, Kohler’s first hybrid alternative solution design that solves the problem of onerous after-treatment for intermittent cycles, to the versatile-hybrid version, which enables electric-only operation.

The new P2 option achieves zero-emissions through full-electric operation while keeping the diesel engine ready to step in to add mechanical power when needed or to recharge the battery.

The new hybrid option will be featured in CELA’s new application, the DT40, a ‘spider’ aerial platform with an electric track. The DT40 is already geared to be an electric machine, in that if the battery is fully charged, crawling can be done in electric. Arm movements can also be done in electric, as the hydraulic pump is assembled on the electric machine and the latter can function as either a generator or a motor.

Another cornerstone of Kohler’s strategy is the KSD engine, which has won both the Engine of the Year award from Diesel and the Engine of the Year under 175 hp award at the Diesel Progress Summit. The KSD is in the under-19kW category and features an electronically controlled indirect injection combustion system, as opposed to the standard mechanical indirect injection in this category.

Kohler says this offers advantages such as high low-end torque – 95Nm at 1000rpm for TC/TCA – and better performance at altitude. The KSD enables a low total cost of ownership due to its optimised fuel consumption, extended service intervals and simplified routine maintenance that requires only two tools.

Vincenzo Perrone, president of Kohler Engines, commented, “Kohler sees the future as a multi-energy landscape, with multiple technological solutions to meet future customer needs and requirements. We will continue to invest in engines and expand their production. We will improve engine efficiency, even in the smallest HP, and develop electronic controls on small engines.

“We will pursue the development of hydrogen solutions that have the same performance as diesel units, as well as natural gas and biogas engines. We will continue to bring to market hybrid modules.

“In summary, we are investing in a diversified energy future, in which a wide range of power options and multiple technologies will coexist for many years."