The company has set out its new strategy toward a more sustainable future, revealing its long-term plan and next steps to transform the group from a power producer to an energy supplier.

The company says the unveiling of this new strategy comes at a momentous time for the engine industry.

Kohler’s strategy incorporates alternative fuels, electrification and hybridisation to reduce engine size or achieve zero emissions during operation, together with introducing hydrogen as a potential ‘green’ fuel.

The manufacturer recently acquired electric vehicle and hybrid applications company Curtis. Kohler says the acquisition expands and diversifies its product portfolio, leveraging Curtis’ expertise in electrification, and solidifying Kohler’s commitment to hybrid and electrified solutions.

Kohler’s road map toward electrification has 2025 as its first goal. The company says its vision is to develop sustainable and technically sound EV system solutions to increase the performance of internal combustion engines by placing full electric solutions alongside them.

Kohler is updating its K-HEM series hybrid unit for the combined electric and mechanical power solution. The range will move from the booster hybrid version, Kohler’s first hybrid alternative solution design that solves the problem of onerous after-treatment for intermittent cycles, to the versatile-hybrid version, which enables electric-only operation.

The new P2 option achieves zero-emissions through full-electric operation while keeping the diesel engine ready to step in to add mechanical power when needed or to recharge the battery.

The new hybrid option will be featured in CELA’s new application, the DT40, a ‘spider’ aerial platform with an electric track. The DT40 is already geared to be an electric machine, in that if the battery is fully charged, crawling can be done in electric. Arm movements can also be done in electric, as the hydraulic pump is assembled on the electric machine and the latter can function as either a generator or a motor.

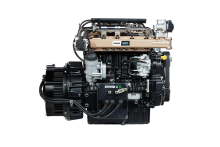

Another cornerstone of Kohler’s strategy is the KSD engine, which has won both the Engine of the Year award from Diesel and the Engine of the Year under 175 hp award at the Diesel Progress Summit. The KSD is in the under-19kW category and features an electronically controlled indirect injection combustion system, as opposed to the standard mechanical indirect injection in this category.

Kohler says this offers advantages such as high low-end torque – 95Nm at 1000rpm for TC/TCA – and better performance at altitude. The KSD enables a low total cost of ownership due to its optimised fuel consumption, extended service intervals and simplified routine maintenance that requires only two tools.

Vincenzo Perrone, president of Kohler Engines, commented, “Kohler sees the future as a multi-energy landscape, with multiple technological solutions to meet future customer needs and requirements. We will continue to invest in engines and expand their production. We will improve engine efficiency, even in the smallest HP, and develop electronic controls on small engines.

“We will pursue the development of hydrogen solutions that have the same performance as diesel units, as well as natural gas and biogas engines. We will continue to bring to market hybrid modules.

“In summary, we are investing in a diversified energy future, in which a wide range of power options and multiple technologies will coexist for many years."