The major engine makers are now working on a range of solutions to provide customers with cleaner power options for the future. The need to reduce global carbon emissions is driving the engine manufacturers to invest in new technologies. Internal combustion engines do have a future with various fuels offering options and the diesel is being transformed, while other power sources, most notably electric, are being made available. Many of the newest internal combustion engines from the key engine firms are designed to be fuel-agnostic. This will allow the use of different fuels as required.

Caterpillar claims that its new C13D diesel offers the highest power density for its class, replacing the previous C13B engine. Because of its high power output, the new C13D unit will be able to replace the firm’s own 15litre engine and even the 18litre diesel for some installations.

Development of the engine has utilised some of the latest digital technology, with the firm assessing assembly and servicing to optimise these processes, even before the unit was in the metal. Designed to meet future requirements, the engine is already able to use HVO and is being tested on B100 biofuels. It has the potential also to be modified to run on propane or even hydrogen.

There are eight power ratings for the six-cylinder engine, which meets the current Tier 4 Final and Stage V emissions requirements. However, the unit has also been designed with the capacity to be able to meet the Tier 5 and Stage VI requirements, if and when these are introduced.

The new engine platform is 10% more efficient and offers an increase in power of up to 20% and up to 25% more low-speed torque than the previous generation Cat engines in its class. It is designed to perform at altitudes of up to 3,700m and in extremes of ambient temperatures as high as 60°C and as low as -40°C. Engine oil and service schedules have been extended due to the engine’s high efficiency and clean running. Engine life is likely to be long, with key components able to be reworked for reuse.

So far, Caterpillar has carried out around 12,000hours of engine testing, with the C13D now being used in the field to further prove the design. And Caterpillar is confident that the unit will meet customer demands when it is ready for market. Scheduled for production in 2026, the Cat C13D will be equipped with Cat Digital Services, an integrated suite of software and hardware solutions supplying the information equipment owners need to secure the health of equipment and minimise downtime

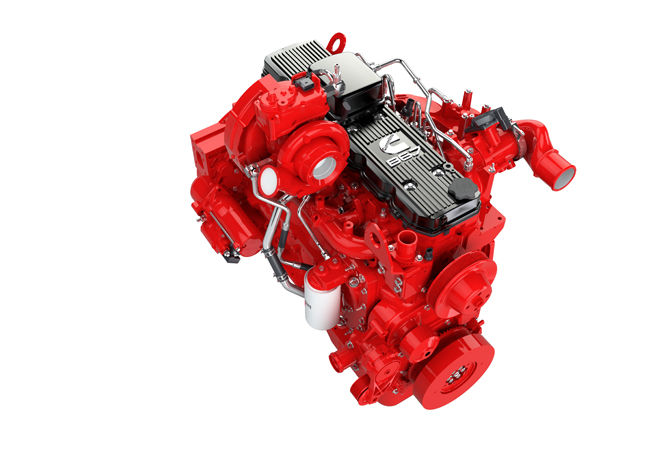

Cummins is introducing a fuel-agnostic engine platform able to run on hydrogen, biogas and diesel. This innovative 15litre engine is said to offer OEMs the opportunity to accelerate the decarbonisation of heavy-duty off-highway applications.

The new platform is designed for the next level of emissions controls and offers a significant increase in power density with a compact installation envelope. This allows OEMs to increase machine capability and productivity with no impact on running cost.

The fuel-agnostic architecture of the engine uses a common base engine with cylinder heads and fuel systems specifically tailored for hydrogen, natural gas, diesel and biofuels including HVO.

The 15litre hydrogen engine will be available with ratings from 300-400kW and a peak torque of 2,600Nm. For applications powered by renewable biogas, this engine will offer slightly lower power ratings with a peak torque of 2,500Nm available. The diesel version will offer a broad power range of 335-485kW, with a 3,200Nm peak torque.

The firm has also invested in developing its portfolio of electric power solutions, buying a number of specialist motor and battery businesses. In addition, the company has extended its range of hydrogen solutions with technologies for producing green hydrogen as a fuel and for fuel cell systems.

Deutz believes electric motors will become more common in the future but is extending its range of internal combustion units. The firm believes 100kW is the threshold for electric power and says that electric motors provide an effective solution for smaller machines requiring less power.

The new Deutz TCD 3.9 engine has been developed in partnership with John Deere and can be fuelled by diesel or lower-emission alternatives such as hydrogen and HVO. It provides 130kW. Deutz has also developed the TCG 7.8 H2 hydrogen engine, a six-cylinder unit based on an existing design that can produce 220kW.

FPT Industrial has released two compact engines, which benefit from its research in SCR technology and the firm holds a number of patents on the technology. The company’s engines require only 7% EGR, reducing the size of the radiator and this has resulted in the new F34 and F36 Tier 4 Final/Stage V engines being compact and light.

The F34 powerpack offers low operating costs and easy maintenance in a compact layout, making it easy to install on machines for OEMs. The Tier 4 Final compliant unit has no DPF, minimising engine downtime and operating costs with a 600-hour service interval. Engine displacement of the F34 is 3.4litres. Maximum power is 55kW and torque is 318Nm.

However, FPT is also exploring hybrid, battery, biodiesel, methane, hydrogen fuel cells, combustible hydrogen, e-axles and e-transmissions.

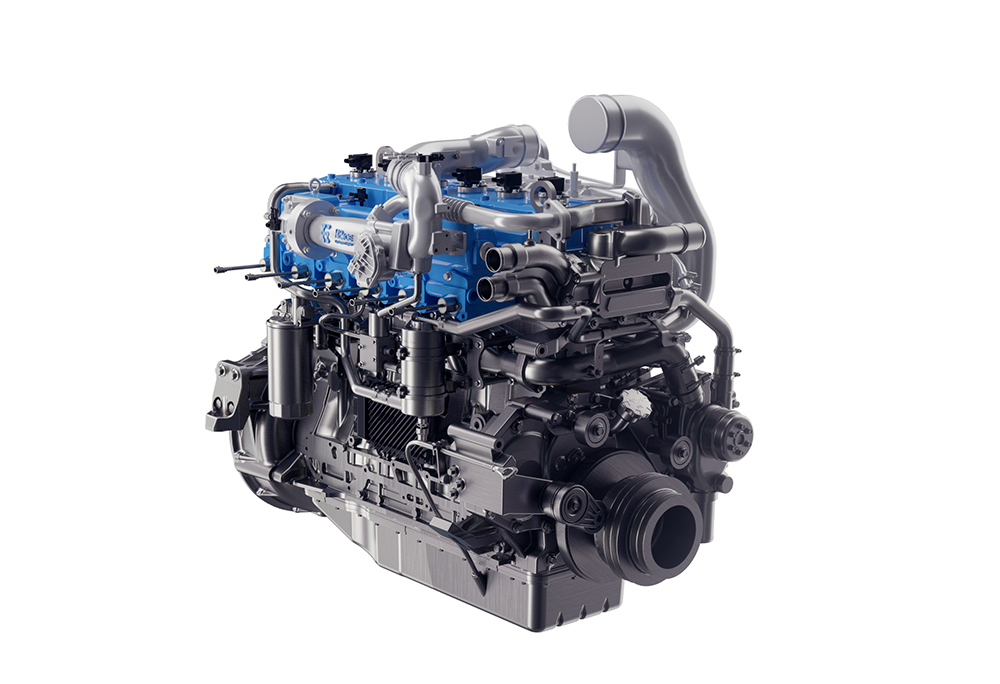

Hyundai Doosan Infracore (HDI) is aiming to mass produce internal combustion engines (ICE). The firm will start full-scale testing of its prototype ICE unit that runs on hydrogen in 2024, to be followed by mass production in 2025.

The firm has completed the design of its hydrogen ICE unit, an 11litre class engine that produces a power output of 300kW and a torque of 1700Nm at 2000RPM. It meets the Tier 5/Stage 5/Euro 7 regulations which require the emissions to be 90% reduced to the current level to meet Zero CO2 (below 1g/kWh) and Zero Impact Emission (Zero Emission in EU).

Refuelling takes 10 minutes and enables a distance of up to 500km, and HDI says that the units are 25-30% more economical than fuel cells or battery packs when vehicle price and maintenance costs are considered. HDI is also introducing EV battery packs and plug-in full hybrid powertrains so that customers will have power options.

John Deere Power Systems (JDPS) has a Next Generation engine line-up that includes the JD4, JD14 and JD18. The engines are said to provide maximum power for a compact size and enable the use of diesel or alternative fuels. The 3.9litre JD4 provides up to 120kW and fills a gap in the range beneath the current 4.5litre model. All the JDPS Next Generation engines can integrate alternative fuels such as renewable options, a key future benefit in moving toward a low-carbon future. The company is also offering a portfolio of electric power options, with its sister firm John Deere already unveiling compact construction machines featuring all-electric power.

The Kohler Small Displacement (KSD) engine is a state-of-the-art unit for the under 19kW class. Benefiting from an innovative electronically-controlled indirect injection combustion system, performance is said to be maximised in every operating condition. High low-end torque values allow operation at low engine speeds, saving fuel. The electronic injection system results in no visible black smoke, while noise and vibrations are minimised.

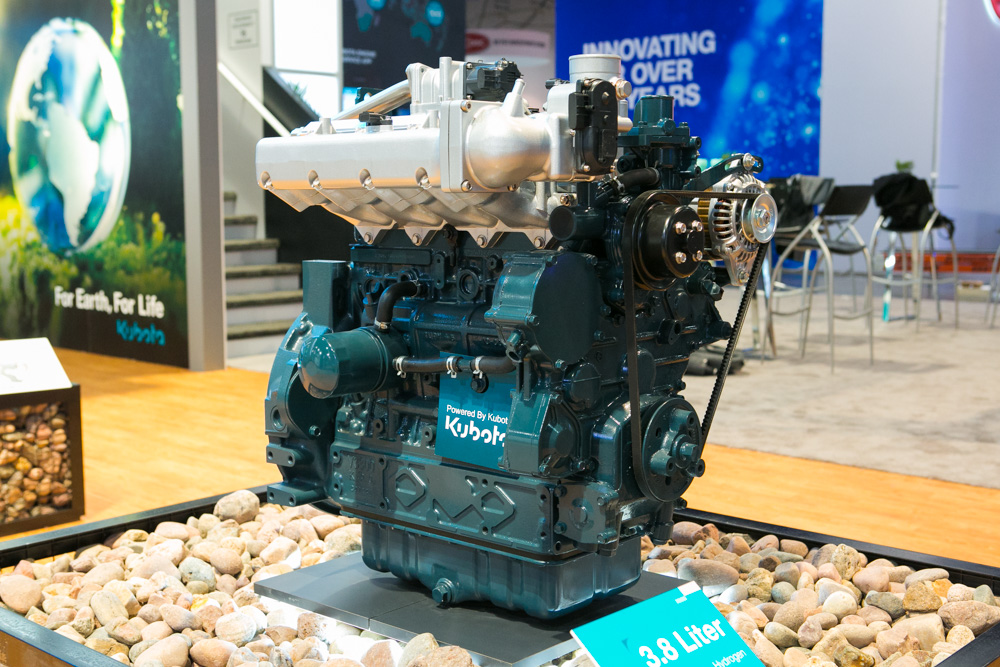

Kubota is introducing a new 3.8litre internal combustion (IC) engine that runs on hydrogen. This four-cylinder power unit features a similar design to petrol/gasoline engines and uses spark ignition, delivering 85kW. The power output suits a number of duties such as a 45kVA generator.

The firm also says that it offers diesel engines able to run on gas to liquid (GTL) and hydrotreated vegetable oil (HVO) fuels complying with the appropriate quality standards, enabling a reduction in CO2 emissions of up to 90% with no engine modifications needed. Kubota believes that a hybrid system combining engine and electrical power is effective for reducing CO2 from industrial engines.

The D1803 P1 Hybrid engine is compact and robust with an integrated motor generator embedded within the flywheel housing. With the P1 Hybrid engine, the motor only assists for the brief periods in which high output is required.

The switch between engine and electric motor drive will be offered with the D1105 P2 Hybrid engine, which offers a rated output of 18.5kW at 3000 rpm. This D1105 P2 Hybrid model also offers the ability to transition between diesel engine drive and electric motor drive while in operation. The advantage here is that in areas where emissions or noise are a concern, the engine can be stopped and switched to the electric motor. Production of the new D1105 P2 Hybrid is scheduled to start in 2025.

In another development, Kubota says that its V3307 Micro-Hybrid engine offers a straightforward design with three main components: a DC converter, a lithium-ion battery and a motor generator attached to the existing engine model. Kubota’s electronically-controlled diesel engine is a three-cylinder diesel engine with a displacement of 0.898litres and an output of 18.5kW at a rated speed of 3600 rpm. Because of the new TVCR combustion system, black smoke emissions have been reduced to an invisible level during startup, acceleration and sudden load.