Sophisticated driveline developments are being seen right across the engine and drivetrain segment, with new low emission technologies being unveiled. High performance and extended service intervals are claimed, while tailpipe emissions have been reduced to meet the coming EU Stage V and latest US Tier 4 Final requirements. But different firms are taking different routes to delivering cleaner tailpipe diesel technologies, with an array of aftertreatment solutions being utilised. Manufacturers have managed to reduce maintenance requirements, with some eliminating diesel particulate filters (DPF) and others ensuring that these units require less attention.

Some companies are preparing electric drive options as alternatives to diesel power, with

Caterpillar has now developed a ‘proof of concept’ version of one of its R1300G underground loaders that features electric drive to its axles, using battery power. This model would suit tunnelling applications while also pointing the way ahead for construction machines for surface applications. It is of note that the project has also included the development of a ruggedised charging system, which would also suit construction or quarry duties.

Cummins is working on all-electric powertrains for use in off-highway applications following its acquisition of the electric drive specialist

Deutz too is investing in hybrid systems and alternative fuels, while also developing advanced low emission packages. The company purchased Torqeedo, a firm supplying electric power units for the marine sector and is using this division to develop power systems for off-highway machines. Deutz has a prototype hybrid powertrain, aimed at use in compact equipment such as small wheeled loaders or telehandlers. It uses a small diesel that runs continuously and also charges the battery, with an electric motor for peak torque requirements. This does away with the need for a larger and more costly diesel, which would also use more fuel.

Meanwhile Volvo CE’s first prototype all-electric machines, a mini excavator and a hauler, have been unveiled and are now undergoing testing. Production models may be some years away but development work is ongoing.

Many companies are also looking at alternative fuel options, most notably gas, with new models due shortly. Cummins, Deutz, FPT and Kubota are amongst those firms with engines either available now or due shortly that can run on gas or other fuels.

But meeting the Tier 4 Final requirements for the US and the new Stage V requirements for Europe have been the focus for research and development budgets in recent times. All the firms have new diesel models, using different methods to meet the lower emission levels.

Benefits include increased performance, improved fuel consumption and starting capability in cold climates, while the aftertreatment system is 39% smaller than the package being replaced.

Meanwhile the C13B is a 12.5litre engine designed to meet Stage V and Tier 4 Final emissions standards, that offers power from 340-430kW and up to 2640Nm of torque, while being 30% lighter than previous models. The engine offers increased performance and efficient aftertreatment regeneration, maximising uptime and fuel efficiency while minimising running costs.

Caterpillar will also certify its existing Stage IV, Tier 4 Final engines in its C13, C15 and C18 product range to meet Stage V emissions standards. Dual label certification – Stage V and Tier 4 Final - will be offered for its range of 9-18litre diesels from 250-597kW.

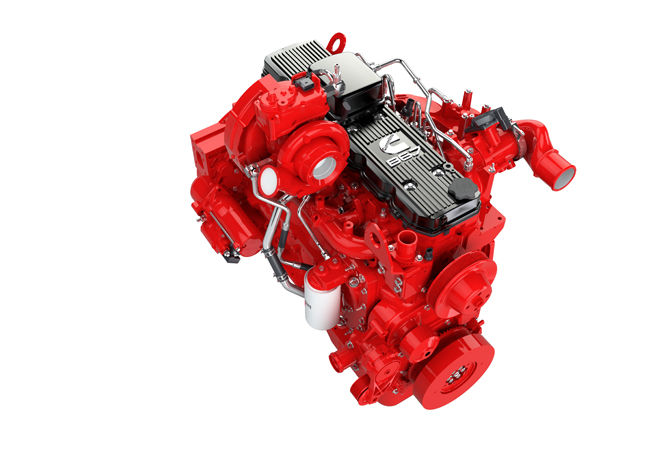

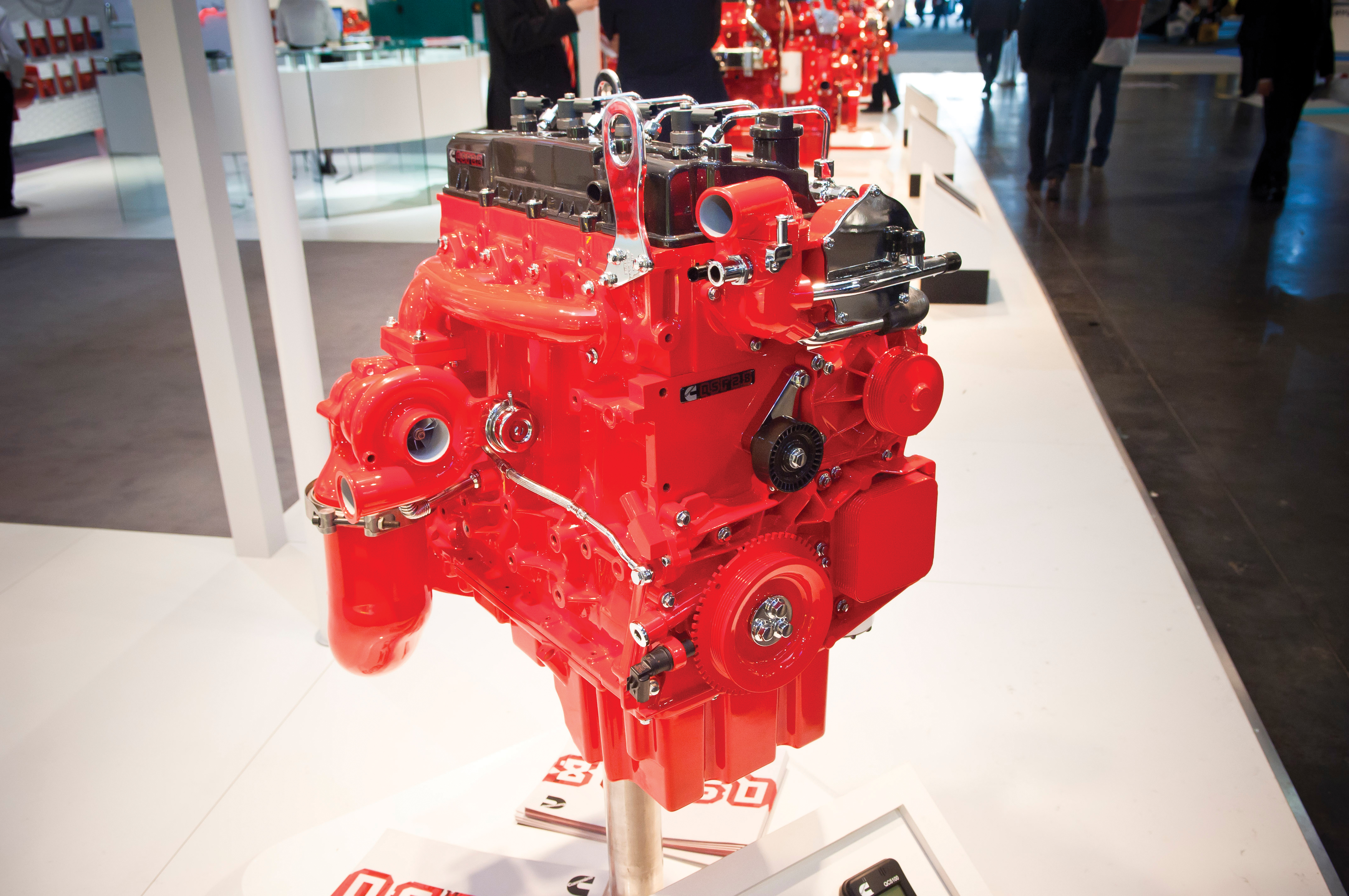

Cummins is proceeding on track with its plan to meet the Stage V European emissions requirements. The firm is now offering Stage V engines with power outputs from 74-503kW and claims the units offer higher performance, more reliability, better productivity, improved fuel efficiency and extended service intervals. The engines are said to be more compact as well as being lighter and easier to install and service.

The single module aftertreatment and its higher NOx conversion capability has supported the removal of EGR from engines in the 3.8-9litre range. Cummins B6.7 and L9 Stage V engines both offer higher power output and torque. The Stage V B6.7 can now deliver up to 243kW, with a 30% increase in peak torque to 1375Nm. The L9’s maximum power has been increased by 23kW to 321kW for Stage V, as well as a 13% increase in peak torque to 1,846Nm.

The F3.8 and B4.5 engines will also be Stage V ready, with substantial gains in power and the 3.8litre unit now delivering 129kW and the 4.5litre engine offering 149kW. A key benefit of its new Stage V engines is that they are more tolerant of high sulphur fuels than the earlier low emission diesels.

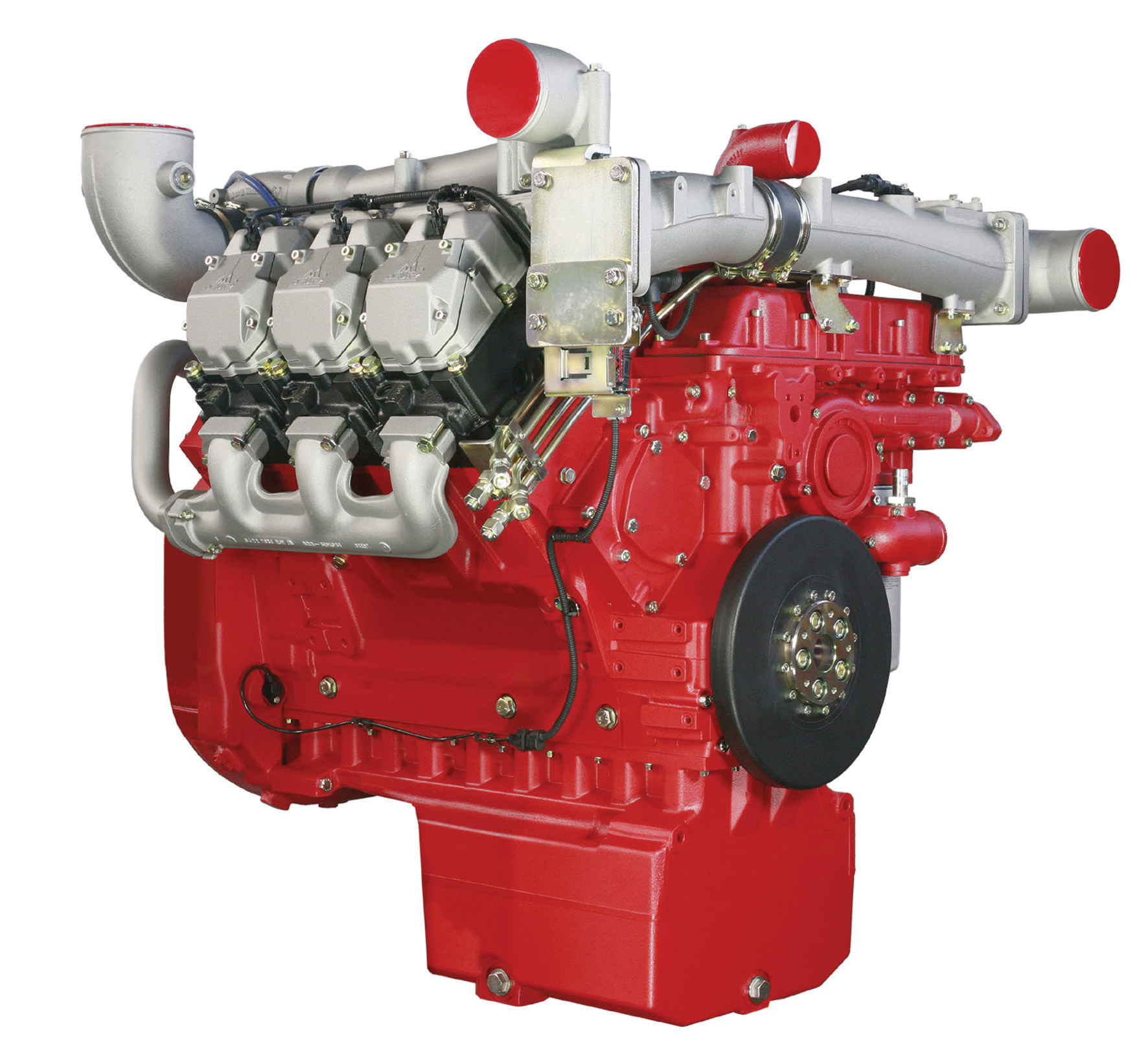

Deutz is broadening its range of low emission engine solutions, with new engines while also boosting the line-up. The 6.1litre TTCD6.1 is the first engine from the firm to have met the Stage V emissions requirements. New too are the latest versions of the TCD3.6, TCD4.1, (T)TCD61 and (T)TCD7.8 engines, which also meet the Stage V requirements.

Deutz’s TCD9, TCD12 and TCD13.5 engines have capacities of 9, 12 and 13litres respectively. These diesels have been added to the range through the partnership with

FPT Industrial is introducing a new low emissions package that will allow the engines to meet the European Stage V requirements. Called the Hi-eSCR2, this patented emissions solution will be used for all engines over 56kW and uses a modular design. A key feature is that the HI-eSCR2 package integrates the filtration system into the SCR module. The patented design simplifies installation and also cuts maintenance needs. According to FPT, the HI-eSCR2 occupies the same space as the previous HI-eSCR aftertreatment used for Tier 4 Final/Stage IV.

FPT is rolling out new low emission engines for the off-highway sector that meet the Stage V and Tier 4 Final requirements. These diesels benefit from proven technology that the firm has already utilised in the on-highway sector in the engines for sister company

The 1.5litre engine competes in the class for under 19kW units and extends the product range of H-series engines, offering a maximum torque output of 130Nm. The Hatz 3H50T achieves its output without an intercooler. It has a compact design without diesel particulate filter (DPF) gives significant benefits particularly for use in compact machines. The Hatz 3H50T engine satisfies current and future emissions regulations, including Stage V and Tier 4 Final.

John Deere Power Systems (JDPS) says that its new engine range will be ready for the Stage V emissions requirements. This also includes the all-new 13.6litre engine, which was designed from a clean sheet.

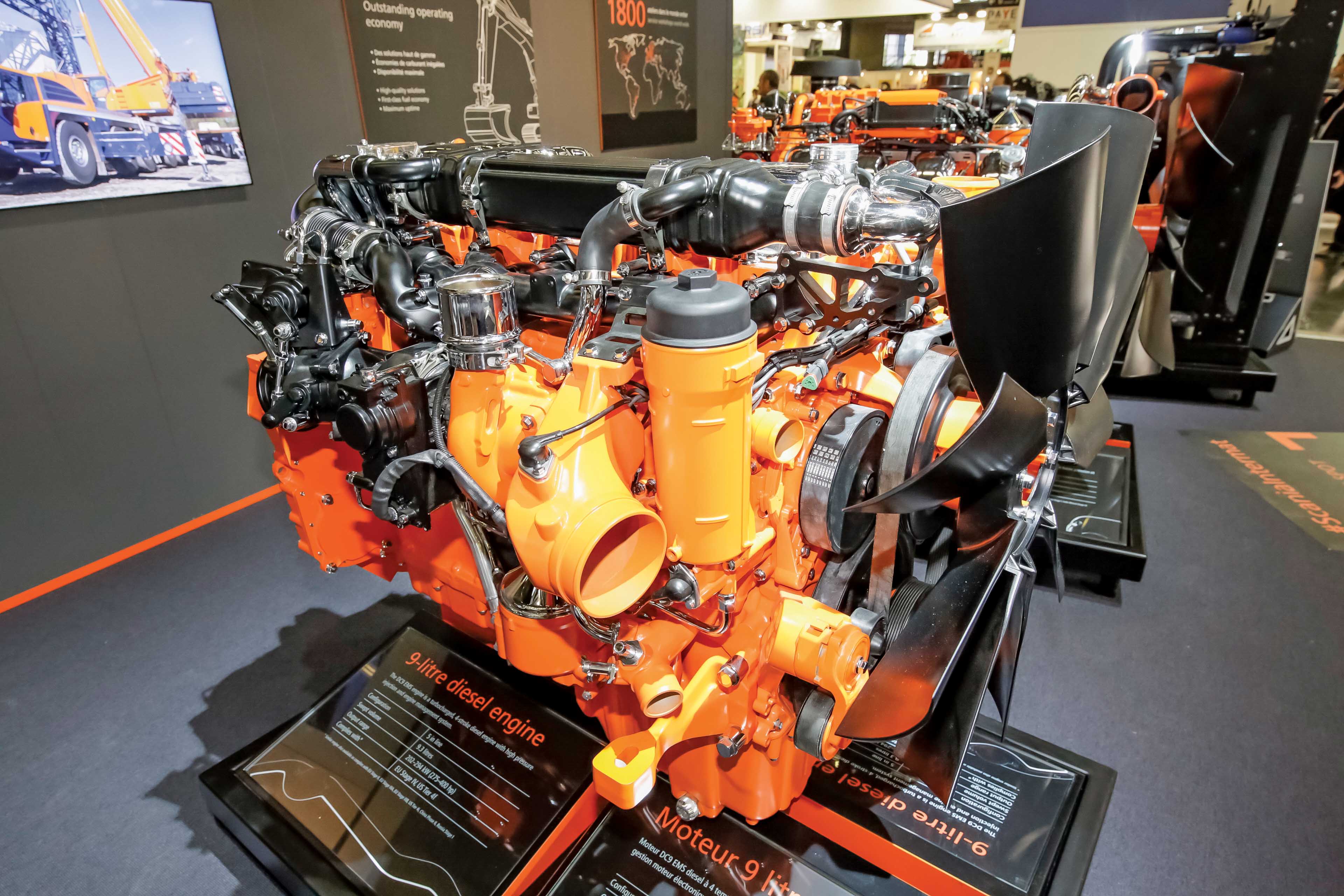

Key features of the new engines are high torque at low rpm, good fuel efficiency and a strong torque response. The Stage V-compliant engines also deliver reliable performance at high altitudes and have capacities of 2.9litres, 4.5litres, 6.8litres, 9litres and 13.6litres, with power outputs ranging from 36 up to 500kW.

The 13.6litre engine is also said to feature an optimised design, which makes it easier to install. Other advantages of this engine include a high power density and high working efficiency, as well as low maintenance requirements.

An improved range of diesel engines has been developed by

The novel DPF smart regeneration system has been developed through extensive use of advanced simulation tools and testing. KOHLER Flex is a range of solutions for emission control and its clean combustion design allows the use of a compact DPF to meet the Stage V emissions standard. KOHLER Flex combines the clean in-cylinder combustion of KDI engines, using high-pressure common rail, four valve head, turbocharger and cooled EGR, and compact aftertreatment devices (DOC, DPF and SCR) to comply with all emissions requirements.

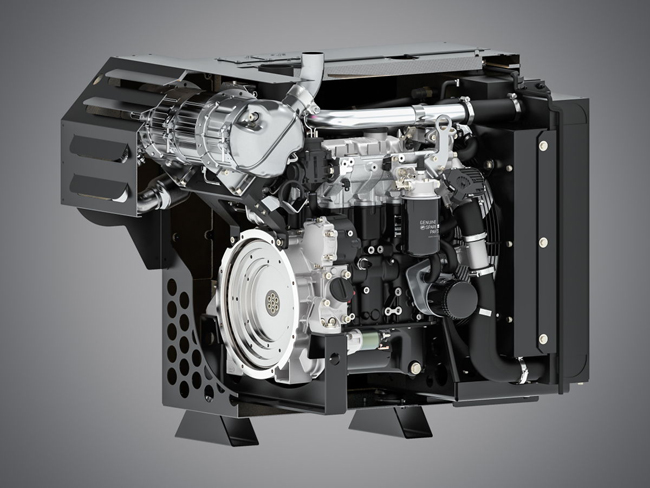

Rolls-Royce’s MTU Series 1000, 1100, 1300 and 1500 engines have been awarded Stage V compliance certificates from the German Federal Motor Vehicle Authority (KBA). The engines have been specially designed for industrial applications and cover the 115-480kW range.

The EU Stage V engines are going into series production and will be available to customers from June 2018, a full seven months before the new directive goes onto the statute books. Customers will continue to be able to source the EU Stage IV engines which will be available alongside the new models.

Volvo Penta is offering new 5litre and 13litre engines that meet the tough European Stage V requirements. The engines benefit from advanced aftertreatment systems and are said to feature the latest technology. High fuel efficiency, low emissions, high productivity and reliability are claimed.

Both engines are part of the firm’s Stage V engine range – D5, D8, D11, D13 and D16, with a power range from 105-565kW. Through its Stage V platform, Volvo Penta offers options for a wide range of off-highway applications.

The new 13litre EU Stage V engine is the TAD1381-1385VE and is said to be powerful, reliable and fuel efficient. This six-cylinder unit has a maximum output of 405kW at 1900rpm.

Meanwhile the new 5litre EU Stage V engine is the TAD580-582VE and is a four-cylinder unit. This is also said to be reliable and fuel efficient, with a maximum output of 160kW at 2200rpm.

Both are designed to deliver maximum power and torque at low rpm, with optimised performance, smooth operation, low noise, and high fuel efficiency. And the two engines feature

The new engines and complementary exhaust aftertreatment system (EATS) comply with the Stage V emissions standards. The EATS includes the following components: Diesel Oxidation Catalyst (DOC); Diesel Particulate Filter (DPF); Selective Catalytic Reduction (SCR); and Ammonia Slip Catalyst (ASC).

Both engines feature a common rail injection system, full authority electronics and after-cooled turbocharging (with a two-stage turbo on the 4TN107 upper ratings).

Both engine families will be Stage V-certified and, says Yanmar, share the same design target of reducing the total cost of ownership. Reducing lubrication oil use was another key design target.

The aftertreatment system consists of EGR and separate DPF and SCR to safeguard durability and ensure exhaust gas cleaning performance. Smaller, separate after-treatment modules also allow for easier installation.