With the Stage V emissions requirements being introduced in Europe, a number of engine manufacturers have already announced their plans. Leading engine makers such as

The new standard introduces the particulate particle count (PN) and applies to all diesel engines above 19kW for off-road applications.

To meet the requirements, firms are using a combination of technologies including: high-pressure, common rail injection; diesel particulate filters (DPF); exhaust gas recirculation (EGR); diesel exhaust fluid (DEF) and selective catalytic reduction (SCR). The various engine suppliers are using different variations (and combinations) of these technologies to best fit their requirements.

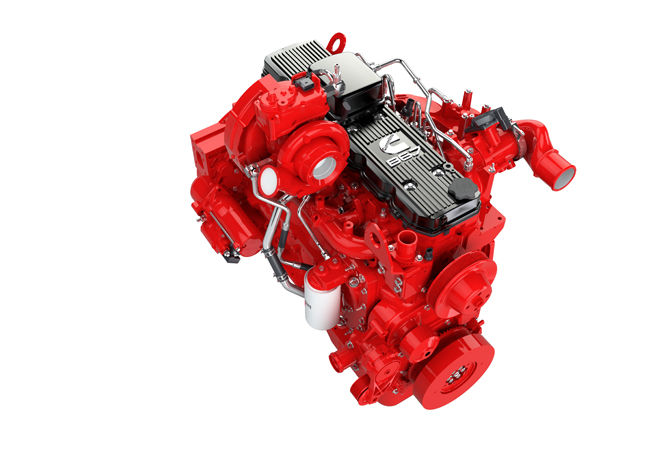

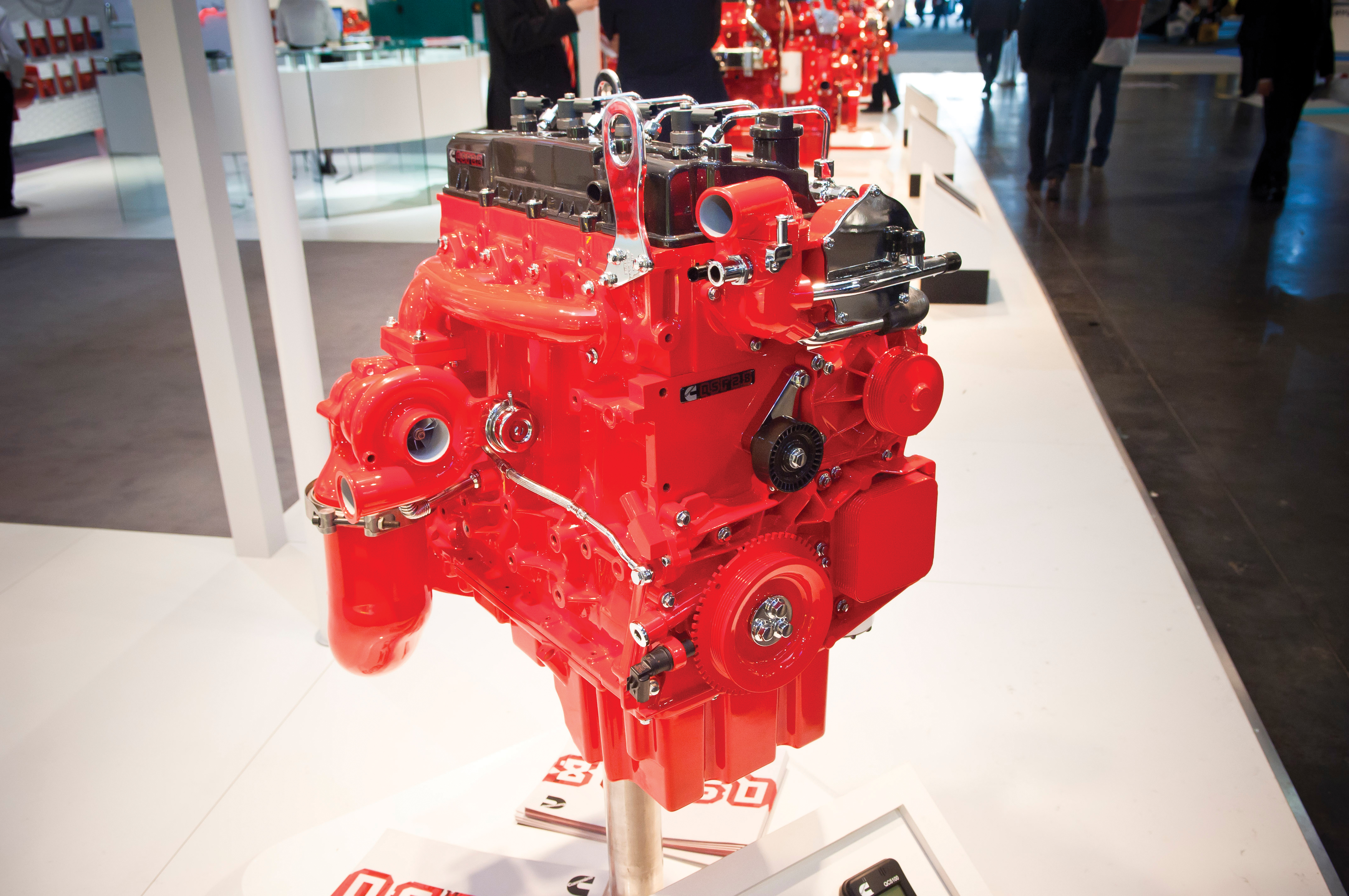

In the market for compact engines,

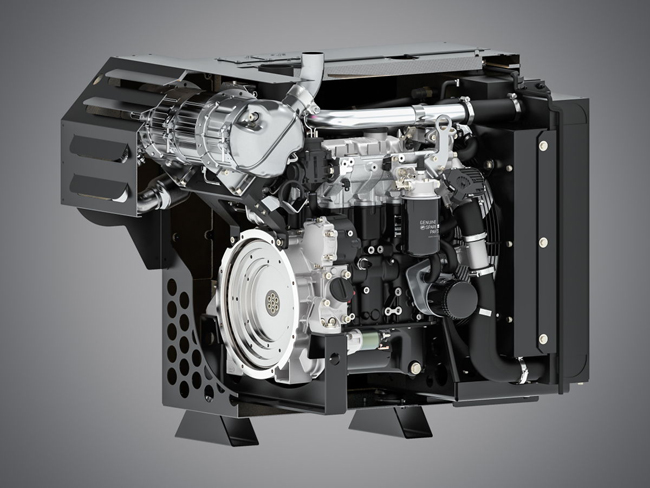

The modular New Silent Pack for the H-series engines from Hatz is claimed to reduce noise emissions, offer optimum protection and require minimum installation space. The New Silent Pack is for the firm’s H-series of three and four-cylinder engines. It is based on open power unit (OPU) engines and can therefore be ordered as complete and ready-to-install variants ex-works. The New Silent Pack can also be used to retrofit existing machines.

The New Silent Pack has a modular structure and is suitable for the Hatz H-series engines 3H50TI, 3H50TIC, 3H50TICD, 4H50TI, 4H50TIC, 4H50TICD. It is said to be easy for machine manufacturers to install, while virtually all parts are identical for all H-series engine variations. A suitable cover for the diesel particulate filter (DPF) is available for the EU Stage V-compliant Hatz TICD models. The maintenance hoods are adapted to the dimensions of the three- and four-cylinder engines.

The low weight of less than 100kg assists manufacturers who need to keep their machines as light as possible. In the three-cylinder TI and TIC model versions, the encapsulation weighs only 91kg, while the largest version, the Hatz 4H50TICD, weighs 98kg.

Similarly, Kohler has achieved Stage V certification for its KDI units and for all the firm’s engines in the 19-56kW power range.

Kohler is building on its experience with the KDI range of engines. The firm is introducing the KOHLER Flex range of solutions for filtering emissions. Designed by Kohler, this is said to allow any KDI engine configuration to be compliant with all the standards and regulations on emissions anywhere in the world.

The engines retain the compact footprint of the KDI range, making the units easy to install for OEMs. The units are said to benefit from an effective regeneration stage that also has no impact on productivity and efficiency for the machine.

Another development from Kohler is said to be its K-HEM (KOHLER Hybrid Energy Module), a hybrid electrical and mechanical combined power generation unit.

The K-HEM unit generates power using a combination of a KDW 1003 18kW diesel engine, compliant with Stage V standards and without DPF, and a 48V electric motor that provides 15kW of peak power and 9kW of continuous power. This allows the unit to provide over 30kW without the need for aftertreatment systems. In addition, the K-HEM unit can operate as a generator for energy accumulation systems.

The diesel provides the power base while the electric motor helps with peak demand for power. This system complies with the Stage 5 standards and makes it possible for machines to avoid derating, while ensuring high productivity. It features a built-in master control that allows users to monitor and manage working modes and transitions.

Integrating and internal combustion engine with an electric motor actually helps to reduce complexity as there is no aftertreatment and the combined system can also store and use excess energy due to the built-in alternator; energy recovery during braking and exhaust phases. It also offers the ability to manage operations using the master control, better fuel economy, a reduction in noise and exhaust emissions and improved performance.

The diesel unit provides power continuously while the electric motor functions as a generator for energy recovery during braking or low power requirements. It also functions as an additional drive for peak power requirements exceeding the 18kW output of the diesel, allowing a maximum of 33kW from the combined system.

Because the diesel and electric motor are integrated, the combined package can be installed just as easily into a machine as a conventional diesel power units. The package is governed by a master control unit to ensure efficiency.

In the compact engine sector, Yanmar has also achieved certification for EU Stage V emissions standards. Yanmar has a list of diesel engines that are certified for compliance with the European Stage V off-road emissions standards. Yanmar has acquired certification not only for the stricter NOx and PM/PN standards on the 19kW and over range, but also for the newly imposed emissions standards for the under 19kW range.

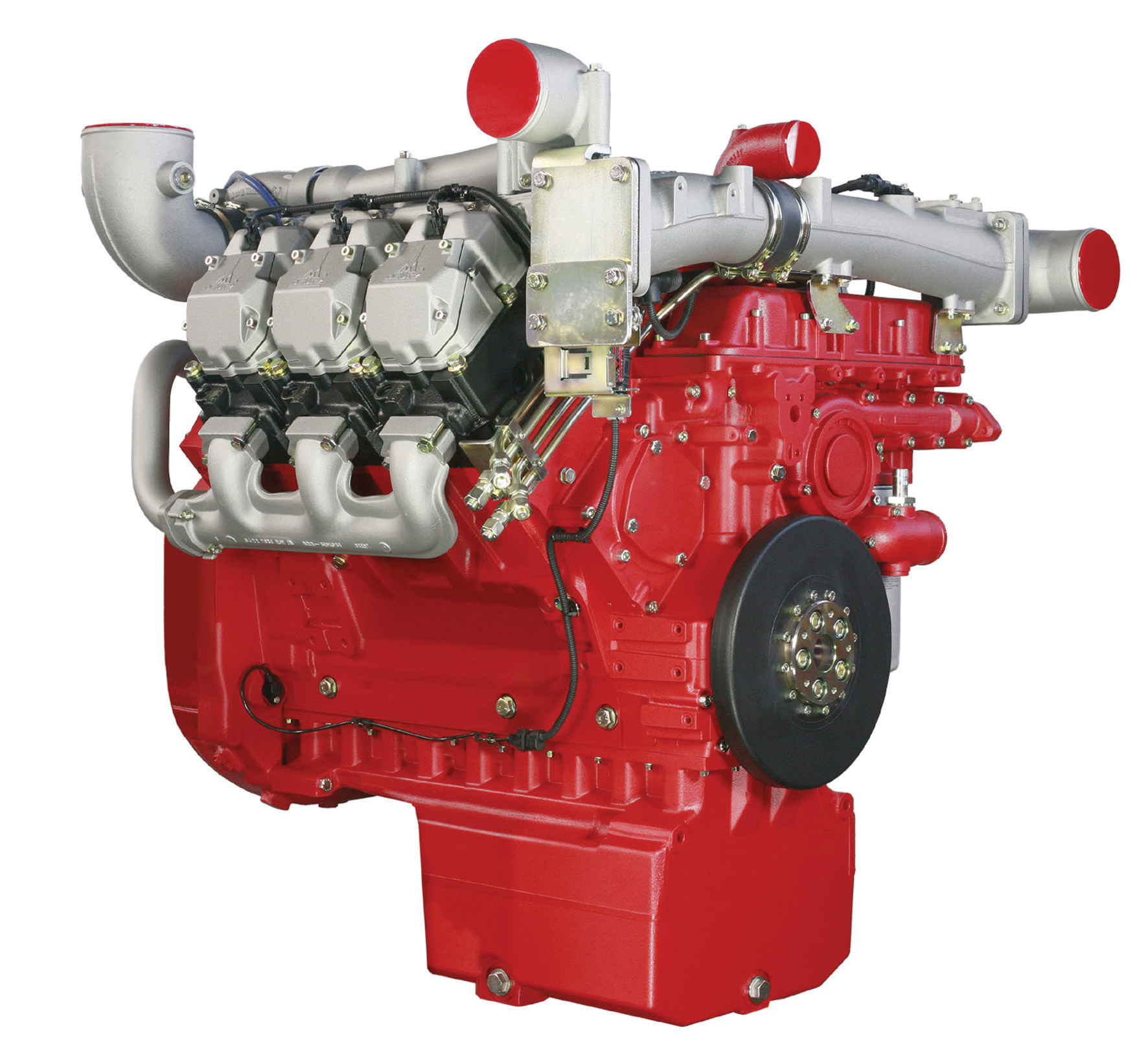

Moving up a size, the industrial Stage V lineup from John Deere is offering ratings of 36kW to more than 500kW, with engine displacements of 2.9litres to 13.6litres.

Because the technologies are built on the same engine platform as current Stage IV DPF solutions, the need for OEM's to re-engineer due to hardware or mounting changes is reduced. Meanwhile, the latest 13.6litre engine is said to offer versatility for installation due to its compact design.

And Volvo Penta says it has prepared its engine offering to meet the challenges of the EU Stage V emissions legislation. Volvo Penta is offering a range of solutions for its engines, such as its exhaust aftertreatment system (EATS) to reduce emissions, as well as an electric driveline.

The EATS system is said to perform well in tough off-road applications and the firm says that its Stage V engines are easy to install, operate and maintain, with power outputs from 105-565kW. The firm is also working on an offering for electric drivelines across its range, by 2021. Advances in electric-drive technology and improved battery capacity are underpinning developments.

A buzz for electrics

There is certainly a buzz in the industry about electric drives. Batteries are gradually improving in performance and reducing in cost. The economics will become positive for electric machines in an increasing number of industry niches. This change will be gradual and many predict that it will play out over a period of 20-30 years.

Perkins has a number of research initiatives in electric and hybrid vehicles, but believes that it is not necessary to wait to improve sustainability, operating costs, noise and local air quality. The latest generation of Stage V diesel engines already have a greater than 95% reduction in NOx and particulates compared to engines prior to emissions regulations. The fuel consumption is also better, partly through engine improvements but also through better integration with other components such as hydraulics, transmission, controls and automation.

There is however potential for further innovation in liquid fuels as part of a long-term shift away from fossil fuels. One example is the latest generation of biofuels, such as hydro-treated vegetable oil (HVO) perform very well with little or no change to engine systems.

But the logistics of refuelling construction machines with gaseous fuels are problematic, whether fuels are burned in internal combustion engines or feed fuel cells. And for construction machines there is no economic or workable solution to these logistic issues for most applications.