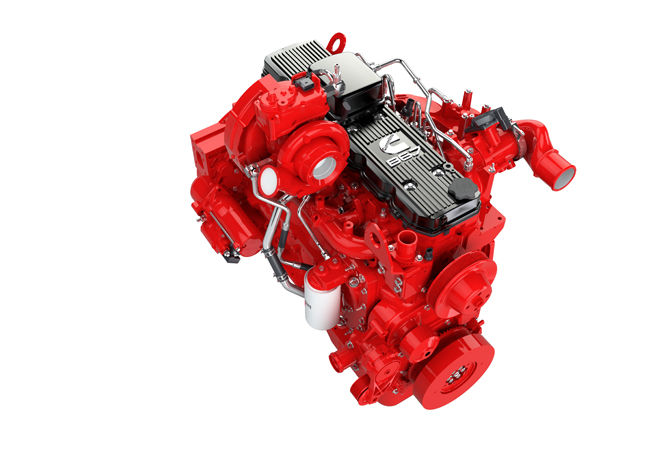

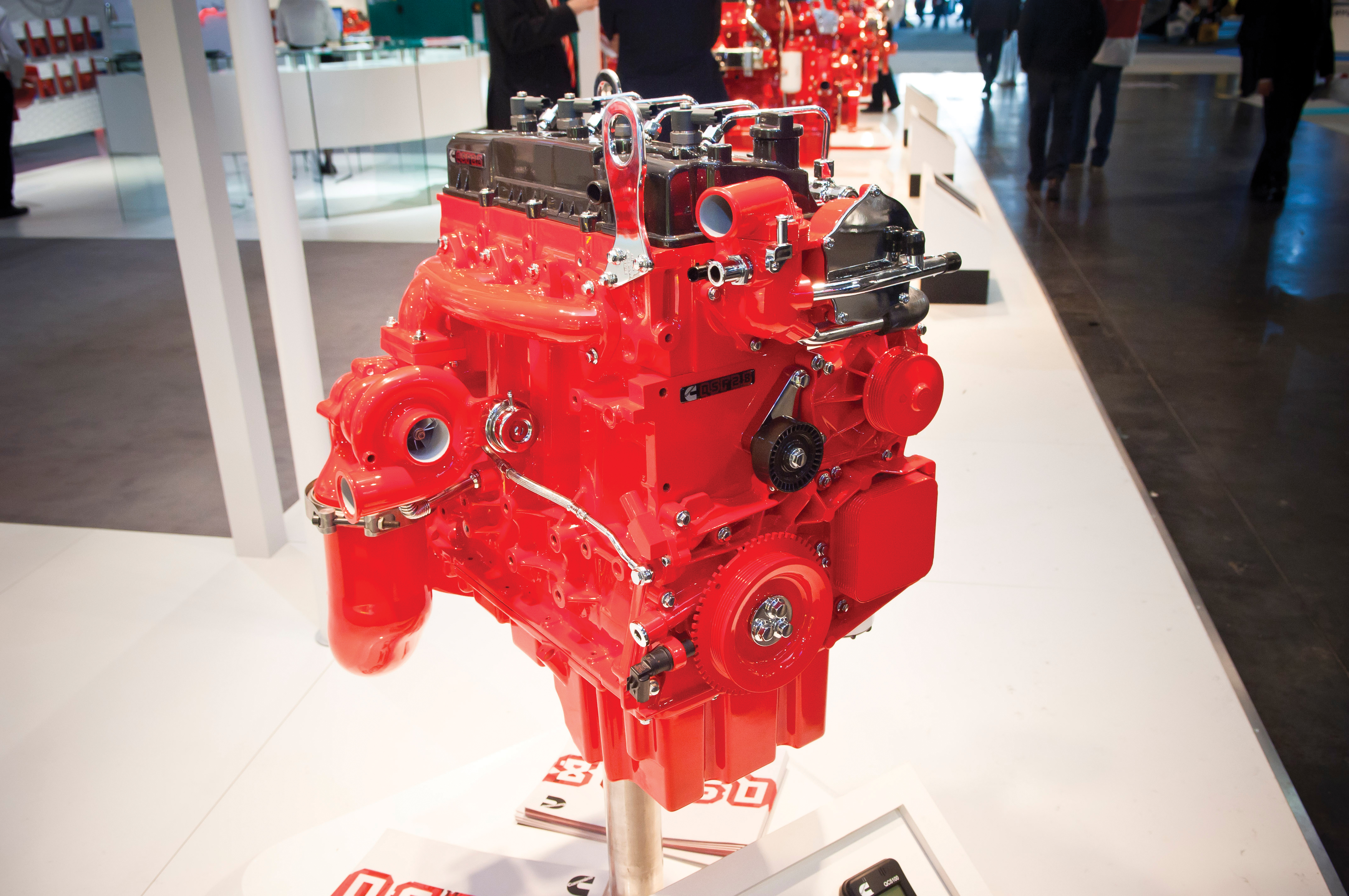

New advances in engine technology are delivering major gains in performance. Maintenance intervals have been extended and the latest emission control systems are more compact and require less attention than previously. Meanwhile, other power options for off-highway machines are being explored: gas engines, hybrids and electric drives are all under consideration for certain working applications.

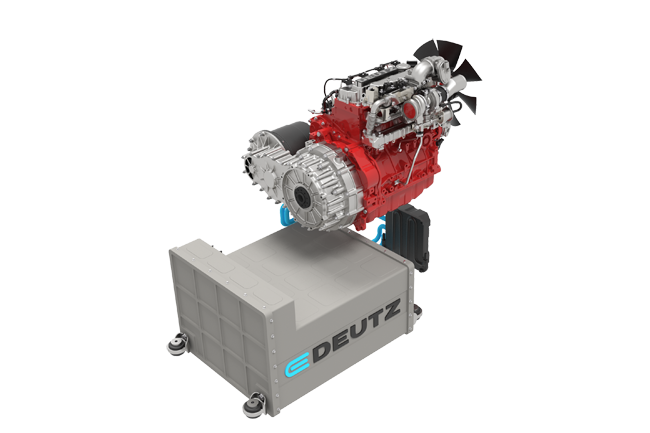

For example, Cummins and Deutz in particular have invested in expanding their portfolios for the electric drive segments.

FPT Industrial has made key advances with its gas engine systems, which are well proven in the on-highway segment and give the firm the knowledge to use its technology in off-highway machines. In addition, John Deere Power Systems has developed a proven diesel electric drive system for heavy machine applications, while Kohler now offers a sophisticated hybrid package and MTU and Volvo Penta have further refined their low emission diesels.

A radical move from Cummins is its signing of a partnership deal with Hyundai Motor Company. This will combine the fuel cell systems developed by Hyundai with the electric powertrain, battery and control technology in the Cummins Group.

The initial focus of this programme will be for the on-highway segment for North America. However, it is clear that the on-highway segment will provide a good proving ground for the technology in the off-highway segment. Fuel cells offer a way ahead for the off-highway machine segment, combining the low noise and clean operation of electric drives with extended range capability.

The companies have stated that they will also explore ways to work together to develop next generation fuel cell systems, and have each committed to assign a team to investigate and pursue other areas of collaboration. The partnership will help Cummins to enhance its electrified power product portfolio by adding Hyundai’s advanced fuel cell technologies.

The MOU comes at a time of heightened demand for fuel cell technology. Hydrogen can be produced from renewable sources, stored economically, and deployed for a diverse range of industrial and residential energy-generation applications. Energy experts predict hydrogen will become increasingly important in meeting fast-growing global energy demand, while also supporting efforts to drive down carbon emissions from energy generation.

Of note too is that Cummins recently unveiled a zero-emission class 8 truck with fuel cell and battery electric power. The hydrogen fuel cell truck is ideal for vocational applications such as urban delivery operations. It features a proton exchange membrane (PEM) fuel cell from Hydrogenics, which was recently acquired by Cummins. The truck features a 90kW fuel cell and is scalable up to 180kW. It comes with a 100kWh lithium-ion battery capacity.

John Deere says that its innovative diesel electric drive technology for wheeled loaders is now extremely well-proven. By early 2019, the firm had clocked over 1 million operating hours with its novel drive system as fitted to its 644K and 944K wheeled loaders. John Deere Power Systems now says it can leverage its expertise to help OEMs adopt electric drivetrain components.

While off-highway equipment manufacturers continue to research hybrid and electrification solutions, the demands of the end customer for reliability and productivity continue to increase. According to JDPS, it now has technologies to reduce emissions, improve fuel economy, and boost machine performance and reliability.

The OEM electrification approach of JDPS can offer integrated solutions that address the interfaces between the electrical generator and/or motors, power electronics, and mechanical interfaces.

Meanwhile, the firm also claims Stage V compliance for key models in its engine range. This includes its variable speed engine families below 56kW and above 130kW as well as its constant speed engine families. The Industrial Stage V line-up from John Deere now offers ratings from 36kW to more than 500kW, with displacements of 2.9litres up to the new 13.6litre unit.

The company says key features include increased uptime and low operating costs. The firm’s new Stage V aftertreatment technologies are said to be optimised for flexible integration.

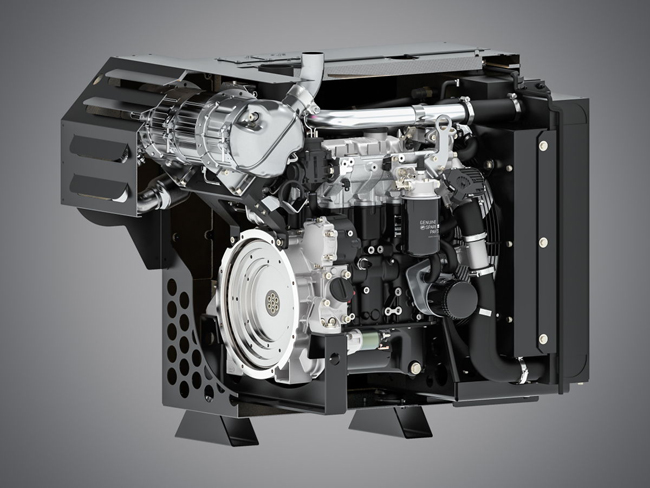

Kohler says that its hybrid electrical and mechanical power generation unit is compliant with Stage V standards but does not require a DPF.

Called K-HEM (Kohler Hybrid Energy Module), the unit features a KDW 1003 18kW diesel and a 48V electric motor. This package can offer more than 30kW without the need for exhaust gas aftertreatment systems. It can also operate as a generator for energy accumulation systems.

The dual function of the electric component works as a generator and auxiliary engine, allowing users to recover energy from the transmission system during the machine’s braking and exhaust phases and from the combustion engine during phases with low energy demands. The energy stored in the battery is available when the machine requires more power.

Both the hydraulic or electrical systems can manage each actuator depending on specific requirements and controlled by the master unit. The firm says that this novel hybrid unit can be integrated into a hydraulic system or a mechanical transmission to ease installation.

According to MTU, its Series 2000 industrial engines can achieve Tier 4 Final and Stage V emissions requirements without aftertreatment. At the same time, the firm says that engine performance, fuel efficiency and durability have been boosted while the cost of ownership has been reduced.

The Series 2000 engines are 12- and 16-cylinder units with power ratings from 567-1,163kW. The firm says that the new Series 2000 engines deliver up to 10% better fuel economy and have extended exchange intervals for major components, such as injectors and high-pressure pumps, allowing 8% lower life cycle costs than the previous generation.

To meet the requirements without external aftertreatment, MTU has used four key engine technologies: cooled high-pressure exhaust gas recirculation (EGR); regulated two-stage turbocharging; common rail fuel injection; advanced diesel engine controller (ADEC).

MTU claims it has overcome the PM-NOX trade-off. The solution is keeping the maximum combustion temperature low for low NOX emissions, while ensuring a sufficient air-fuel ratio (AFR) for low particulate emissions.

The firm says that the key function of EGR is to increase the thermal inertia of the cylinder charge. At a given engine operating point, which corresponds to a given injected fuel mass, there is also heat produced during combustion, raising the temperature of the cylinder charge. The recirculated exhaust gas provides an additional thermal inertia, leading to lower maximum combustion temperatures.

MTU has patented donor cylinder EGR: a cooled, high-pressure system, featuring donor cylinders. Only four cylinders on the 12-cylinder models supply exhaust gas to the EGR system. The 16-cylinder engines use five donor cylinders. At maximum EGR rate, they provide 100% of their exhaust gas for EGR, while the remaining cylinders supply the turbochargers. The advantage is that only the donor cylinders have to work against high backpressure, pumping exhaust gas into the intake.

MTU’s advanced EGR system is also said to avoid problems such as lower fuel efficiency, visible black smoke, intake systems and intercoolers clogged with soot, and heavy soot-in-oil issues.

Another important feature is the two-stage turbo system, which has a high-pressure stage with one turbo connected in series to a low-pressure stage with another two turbos. A bypass valve for the high-pressure turbine regulates turbo pressure. Charge air cooling is comprised of two stages: an intercooler between the low- and high-pressure stages, and an aftercooler between the high-pressure stage and cylinder inlet. The two-stage turbocharging system also ensures low soot combustion.

Volvo Penta has managed to increase uptime in its latest D5 to D13 off-road engines by minimising active regeneration. The Stage V emissions legislation requires engines to have a diesel particulate filter (DPF), which captures and stores soot. This soot needs to be burned off periodically to regenerate the DPF and this has previously been done while the machine is at a standstill.

But the firm has focussed on minimising the need for active regeneration as much as possible, to keep machines operational. The firm has carried out extensive testing to address the issue of regeneration and part of this involves deliberately installing unsuitable engines in some machines to stress the system and find problems.

Research has also investigated synergies between the base engine and the aftertreatment system so that the diesel and software work together to minimise the need for active regeneration.

For the Stage V off-road platform, the firm developed the engine and aftertreatment system hand in hand, and it has been an ongoing optimisation project for all engines in the range, which share a common architecture.

The firm has installed new water pumps, new oil coolers, new piston rings and new thermostats, which combine to make significant improvements. In addition, the firm has improved fuel efficiency figures.