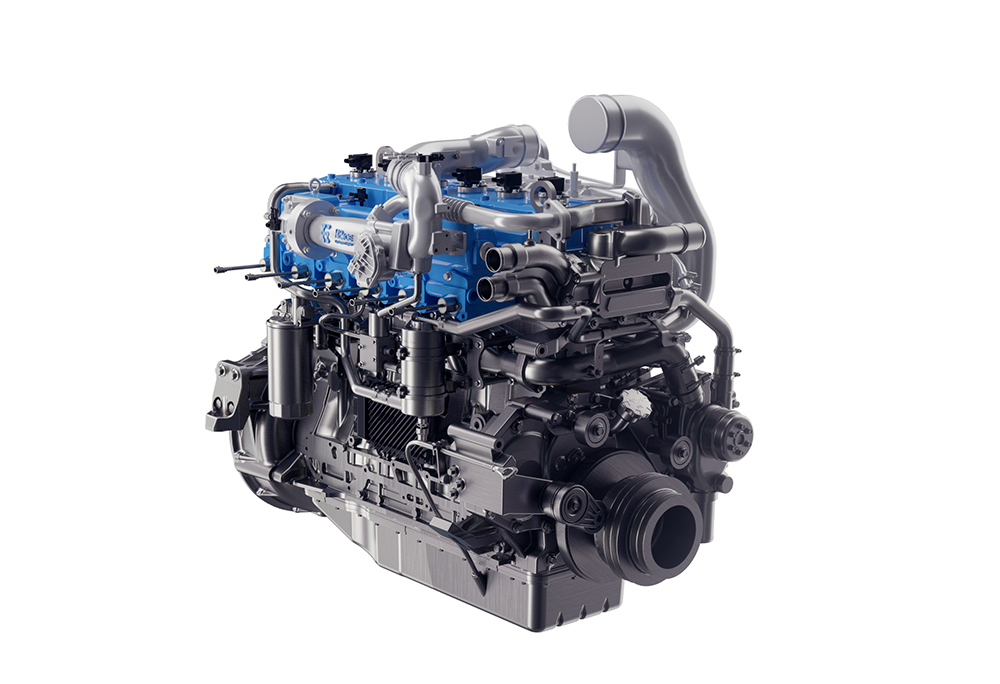

The firm has completed the design of its hydrogen ICE unit, an 11litre class engine that produces a power output of 300kW and a torque of 1700Nm at 2000RPM. It meets the Tier 5/Stage 5/Euro 7 regulations which require the emission to be 90% reduced to the current level to meet Zero CO2 (below 1g/kwh) and Zero Impact Emission (Zero Emission in EU).

Hydrogen engines are powered by low-purity hydrogen, making them durable, economical and energy-dense, which makes them the most suitable engine system for mid-to-large-sized vehicles and vehicles for long distances. A single charge of 10 minutes enables a distance of up to 500km, and HDI says that the units are 25-30% more economical than fuel cells or battery packs when vehicle price and maintenance costs are considered.

HDI plans to leverage its existing engine technology and facilities to reduce costs and accelerate commercialisation. The new hydrogen engines will be installed on commercial vehicles such as trucks and large buses, and construction equipment for validation by 2024, and full-scale mass production is planned for 2025.

HDI is also introducing EV battery packs and plug-in full hybrid powertrains so that customers will have power options.

Booth S84044