All change: get ready to rethink everything

Trimble Dimensions 2022 underway

Berco Aftermarket gears up for business

Berco, a global producer and supplier of undercarriage components for many of the world’s main manufacturers of tracked earthmoving machinery, has launched Berco Aftermarket.

Berco says the new company exclusively serves the aftermarket requirements of construction machinery worldwide, except for North America. This region will be covered by Berco of America, a standalone company 100 per cent owned by Berco.

Piero Bruno, chief executive of Berco, says the quality and performance of the company’s many components found in original equipment machinery will now be available for the replacement parts industry.

At the same time, Berco Aftermarket plans a significant extension of its current product portfolio – far beyond the existing Service Line – to include additional many other undercarriage-related components.

As part of this strategy, the new company is running its recently opened own 12,000m² warehouse in the northern Italian city of Bologna. There, Berco Aftermarket will be partnering with Gruber Logistics, a transport company with expertise in moving heavy loads and special cargo worldwide.

Diego Buffoni, managing director of Berco Aftermarket, noted that the new warehouse will serve as a buffer between the world's largest undercarriage plant and the company’s dealers who require flexibility and short lead-times when purchasing from Berco’s extensive product range.

Berco has been part of the thyssenkrupp group since 1999 and joined the group’s Forged Technologies business, a supplier of components and systems, in 2018.

Earthmoving & soil compaction

Earthmoving & soil compaction

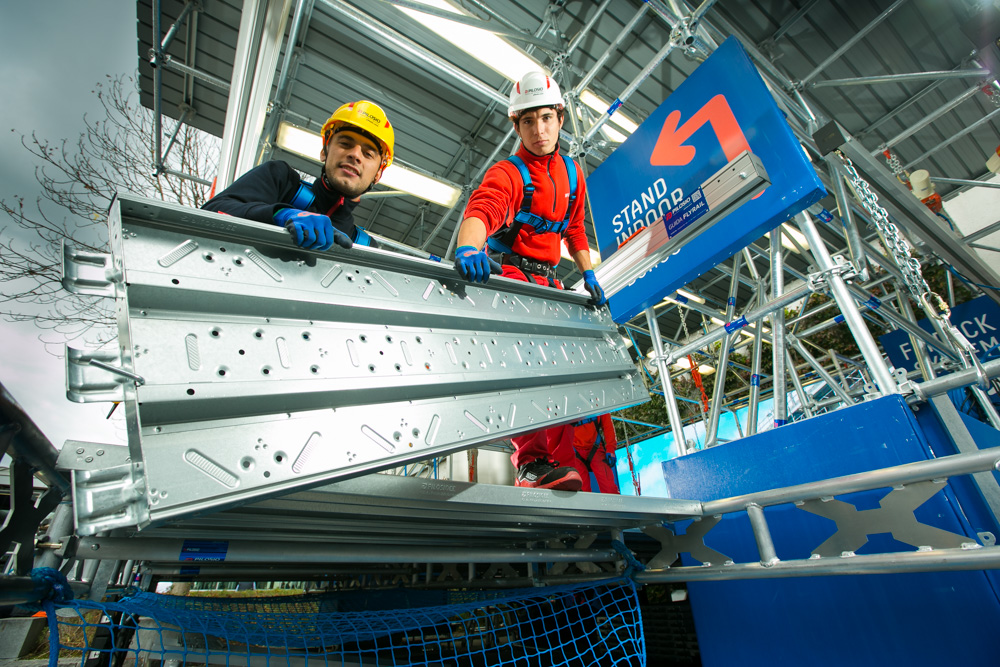

Hanging out with Pilosio's Flydeck

The Flydeck system from Pilosio simplifies and speeds up the assembly of suspended scaffolding and structures safer. Importantly, because it is an under-bridge suspended system, there is no need to stop bridge traffic or close lanes.

The system consists of 25-cm or 45-cm aluminium or steel lattice girders connected by patented pins and spring pins. The girders are installed using the FLYRAIL rail. The Flyrail rail supports the cantilevered girders of the Flydeck surface while the operator arranges the surface and anchors it in full safety.

Loading capacity is up to 150kg/m² with tie-rods every 6m² and loading capacity up to 300kg/m² with tie-rods every 4m².

The result is a perfectly horizontal plane for workers in any situation where a suspended solution is needed. Furthermore, with the use of the Flyrail beam for mounting the Flydeck table, you can work without any difficulty and in complete safety. With this solution, Pilosia says that pillars and pier-caps can be encircled and continued in the next span.

Importantly, there is no limitation in width, length or load capacity. The system is modular and uses beams and scaffolding decks of any make, model, shape and size.

Maintenance

Maintenance

South African route upgrade planned

Mongolia road project underway

Temporary bridge set for Tretten in Norway

Indonesian elevated road project

Estonia road bypass projects delayed

Connectivity is key for contractors

Vietnam bridge project planned

Final Lower Thames Crossing approval awaited

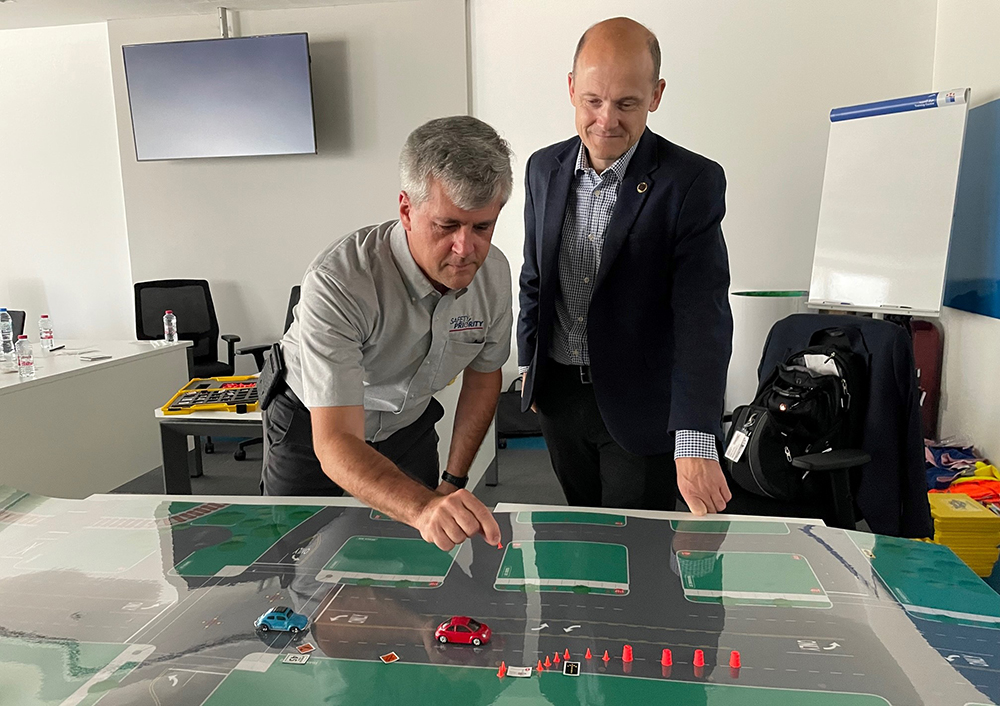

Raising global safety standards for road work zones

Australian transport infrastructure development

IRF’s 2022 GRAA winners announced

New South Wales road refurbishment project planned

Plantworx 2023 is UK gaining momentum

Increasing quarry efficiency in Senegal

Wider application range for mobile crusher