The system, which is still in development, visualises formwork and scaffolding projects in 3D and takes the industry to the next level, says Peri. It optimises communication, safety, and efficiency on the construction site.

Ono-site workers, using an app on their phone or tablet, request information from another employee sitting in a central office where they have access to assembly knowledge.

The onsite workers the pan their tablet’s camera around on site, in the area where the formwork will be assembled.

Meanwhile, the office worker, seeing this image and wearing their 3D goggles, can assemble the required system. Simultaneously, back on site, the team can see this being done on their screen. They then have all they need to finish the job.

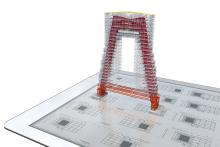

Using augmented and virtual reality, 3D designs can be walked through virtually … or projected into the physical environment. Due to the different visualisation options, the respective models are optimally integrated into the planning and construction process.

Importantly, for clients, the XR Ecosystem allows integration of 3D and BIM models (building information modelling) in the planning and construction process, thanks to different visualisation options.

Peri also points out that the system could be especially useful in remote areas where in-person assistance is not immediately available. It also could be used to train people.