Keestrack Company Profile

Keestrack has a strong reputation for innovative and cost-effective track mobile crushing and screening equipment with a relentless search for the best performance at the lowest cost per produced ton.

Keestrack introduced its hybrid and electric plug-in solutions in mobile processing technology in 2012. At Conexpo Keestrack are presenting an overview of their extensive product range, introducing sustainable full electric plug-in equipment backed up by a drop-off engine/gen-set.

Keestrack, with its Texas based US Headquarters, will be at Conexpo with their American, Canadian and Latin American dealers.

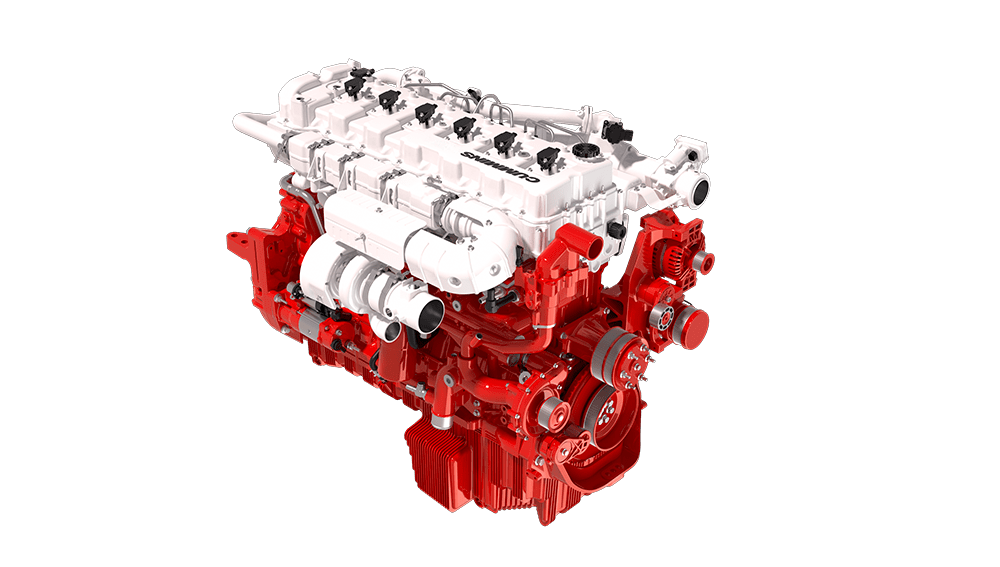

Performance in every detail

The fully electric plug-in R5e impact crusher will be introduced to the American market. The impactor can be powered via mains connection for a zero carbon footprint, or via a gen-set unit, in the event of no available connection to the grid.

The R5e has a drop-off engine/gen-set which can be placed either on the chassis of the machine or besides the machine, connected with a power cable.

Being placed in a less dusty and vibrant environment maintenance is safer and easier when the engine is situated at ground level.

When connecting several machines to a single drop-off engine /gen-set, it results in huge savings as there is only one engine/gen-set to run and maintain.

Also on show: the H4e cone crusher in closed circuit, the award winning R3 impactor, the heavy duty B7 jaw crusher, the most mature and productive scalper on the market, the K6 and the dust suppression cannon W7.

Central Hall, C-31386

Keestrack America

15066 US HWY 380 W

Krum

TX 76249

USA

[email protected]

www.keestrack.com

Matec has decided to strengthen its presence in the American market, where it has been present since 2012 with a sales office and a warehouse in North Carolina.

Matec has decided to strengthen its presence in the American market, where it has been present since 2012 with a sales office and a warehouse in North Carolina.

Our comprehensive portfolio covers crushers, screens, feeders, track-mounted and wheel-mounted units, stationary plants and related digital solutions. Metso Outotec equipment and parts are built to last and are backed by reliable service and support, giving us the unique ability to elevate customers’ business to a whole new level.

Our comprehensive portfolio covers crushers, screens, feeders, track-mounted and wheel-mounted units, stationary plants and related digital solutions. Metso Outotec equipment and parts are built to last and are backed by reliable service and support, giving us the unique ability to elevate customers’ business to a whole new level.

The range includes twelve track-mounted JAWMAX® jaw crushers and REMAX impact crushers between 49,000 and 353,000lbs operating weight (max. output: 250 - 800tph). Their diesel-electric drives enable cost savings of up to 75%, guarantee high availability and improve your environmental footprint. At the booth we will display the JAWMAX 400 jaw crusher.

The range includes twelve track-mounted JAWMAX® jaw crushers and REMAX impact crushers between 49,000 and 353,000lbs operating weight (max. output: 250 - 800tph). Their diesel-electric drives enable cost savings of up to 75%, guarantee high availability and improve your environmental footprint. At the booth we will display the JAWMAX 400 jaw crusher.