Japan’s roads need maintenance and repairs

Using technology to reduce the carbon footprint in asphalt production

Rokbak RA30 & RA40 set to impress

The Scottish articulated hauler manufacturer is making its North American tradeshow debut with its RA30 and RA40 machines.

“We cannot wait to give the RA30 and RA40 pride of place on our stand,” says Paul Douglas, managing director of Rokbak. “We’re looking forward to getting as many attendees interacting with what we’ve got lined up as possible, as well as introducing people to our knowledgeable team who are keen to show off our robust and hardworking haulers.”

“Rokbak is seeing huge demand for its RA30 and RA40 articulated haulers in the US,” says Robert Franklin, Rokbak’s director of sales – Americas. “The US is leading articulated hauler demand globally with huge infrastructure spend. There is a lot of construction activity at the moment around house and road building, so we are keen to meet with customers and potential customers at CONEXPO and discuss how the RA30 and RA40 can help with these projects.”

Rokbak will be showcasing its haulers and aftermarket offer alongside fellow Volvo Group companies Volvo Construction Equipment and Volvo Penta.

With sustainability in mind, the Rokbak event booth materials are all recycled or reusable. Two 40ft customised shipping containers, adorned in the recognisable Rokbak aesthetic, will be used for meeting rooms and product information displays. Following the event, these will be shipped back to Motherwell for reuse at future events.

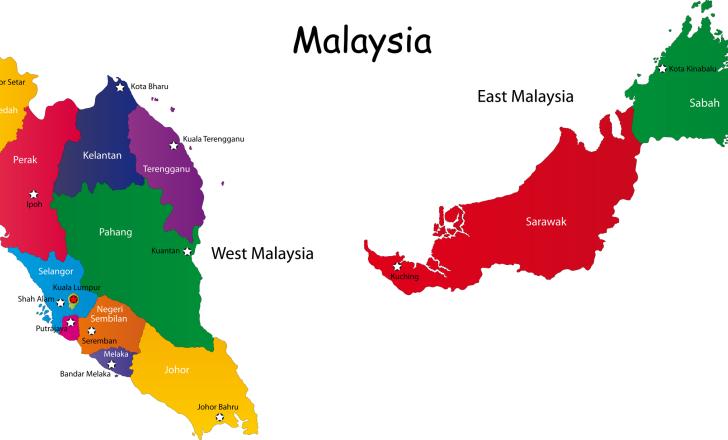

Malaysian highway project on track

Kistler WiM for Caltrans

Cable works starts on Gordie Howe Bridge

Romania road tender reopening

German construction machinery manufacturers bullish

LA1 bridge project faces construction delay

IRF Announces winners of 2022 Global Road Achievement Awards

UK hosts world’s first zero-emissions Portland cement industrial trial

Simex Srl Company Profile

Hydraulic attachments for earthmoving machines

Over 120 models to provide solutions to the most challenging application fields: road maintenance, utilities, trenching, construction and infrastructure, tunnelling, profiling works, demolition and recycling.

Simex attachments are designed and engineered to be exceptionally durable and high-performing. Our product range includes: cold planers, screening buckets, wheel saws, drum cutters, crusher buckets, granulator buckets, asphalt floats & compactors - for excavators, loaders and skid steers.

Simex is the technological partner of choice for countless applications

Since 1991, Simex has designed and manufactured hydraulic attachments for the earthmoving industry. With a range of 30 products and over 120 models providing solutions to the most challenging applications:road maintenance and underground utilities; construction and infrastructure; tunnelling and demolition; recycling and waste material recovery; and agriculture and forestry.

Since 1991, Simex has designed and manufactured hydraulic attachments for the earthmoving industry. With a range of 30 products and over 120 models providing solutions to the most challenging applications:road maintenance and underground utilities; construction and infrastructure; tunnelling and demolition; recycling and waste material recovery; and agriculture and forestry.

With continuous investment and a global vision proudly rooted in its history, today the company’s production plant in Italy covers a total area of 54,000m², ensuring increased stock capacity and shorter delivery times. A large amount of space is dedicated to testing equipment so as to ensure the highest quality standards. A vast demo area allows the R&D office to develop new products, simulating the various fields of application.

This is all complemented by a prompt customer and after-sales service and an extensive sales network covering over 80 countries, with a branch office in Russia and, from 2021, in the US.

West Hall, W43273

Simex Srl

Via Newton, 31-33 - 40017 San Giovanni in Persiceto

BO - Italy

+39 051 6810609

[email protected]

[email protected]

simex.it

simex-na.com

simex-buckets.com

Wirtgen Group Company Profile

Company Information

The WIRTGEN GROUP is an internationally operating group of companies in the construction equipment industry. We owe our strength to the five traditional product brands WIRTGEN, VÖGELE, HAMM, KLEEMANN and BENNINGHOVEN.

As technological leader, we can offer our customers mobile machine solutions for road construction and road rehabilitation, plants for mining and processing minerals or recycling material and for the production of asphalt.

The WIRTGEN GROUP at Conexpo 2023

SMART. SAFE. SUSTAINABLE.

The WIRTGEN GROUP, represented through Wirtgen America, is showcasing its latest developments in all three aspects of smart, safe, sustainable at the joint appearance with John Deere in Vegas. Come to Conexpo-Con/Agg, experience the fascination of our innovative solutions and join us in celebrating the roads we have built together to date. Discover our impressive new products and technologies at first hand.

With 68 machines for road construction, materials processing, earthmoving, and earthworks, we will be demonstrating the enormous expertise and experience you can benefit from when you join forces with one of the world’s leading manufacturers. The four production systems featured in the booth include Aggregates, Site Development, Roadbuilding, and Underground, highlighting core customer business areas. Each production system will showcase key components, equipment, and features, presented first-hand by John Deere and Wirtgen Group brand representatives.

For more information about WIRTGEN GROUP visit www.wirtgen-group.com/conexpo

Silver Lot S5020

WIRTGEN GROUP

www.wirtgen-group.com/conexpo

Innovative technology from Caterpillar at CONEXPO-CON/AGG 2023

Caterpillar customers can ensure equipment uptime by using these tools as well as extended protection packages to help secure investments.

In addition, the firm is unveiling a range of new and upgraded Cat technologies – VisionLink, Cat Command, VisionLink Productivity, Cat Detect, Cat Grade and Cat Payload. These are intended to offers scalable solutions designed to fit varying business needs and budgets. Significant gains in productivity and efficiency are claimed with the use of these tools.

Booth F9127

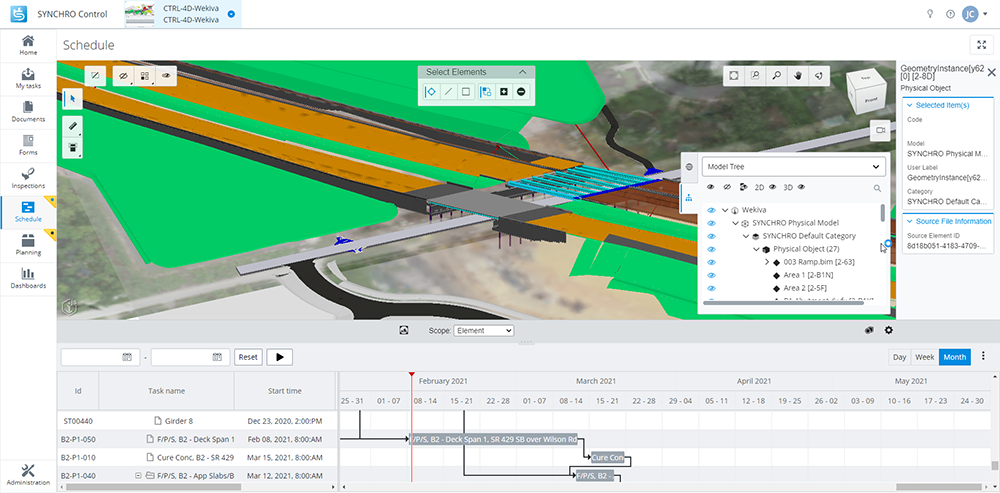

Efficient construction management technology from Bentley

Bentley is able to deliver 4D/5D modelling services to help construction firms and owners generate digital twins for digital project delivery workflows. SYNCHRO’s 4D/5D model capabilities offer advanced construction modelling tools that make it easier to turn design and reality models into 4D construction models. These models can simulate construction operations, deliver model-based quantity take offs (QTO), and leverage the model as context for project task management and collaboration.

Booth N11865

McCloskey is widening its product line

Another new model is the I4C impact crusher, bringing the power and productivity of an 1125mm impactor to a compact footprint for maximum manoeuvrability. The new I54Rv3 offers high quality and high-production capacity for mobile impactor applications. The new ESS-300 tracked primary shredder capable of effectively and reliably shredding a wide range and type of material.

Sister firm MWS Equipment is partnering with Metso Outotec's pump and cyclone division to bring new levels of efficiency to its washing equipment, offering units such as the MR200E Pump and the 650 Cyclone for the North American market.

The company is also introducing a new brand colour scheme that is said to offer a unified and more contemporary look across the product range.

Booth S5411

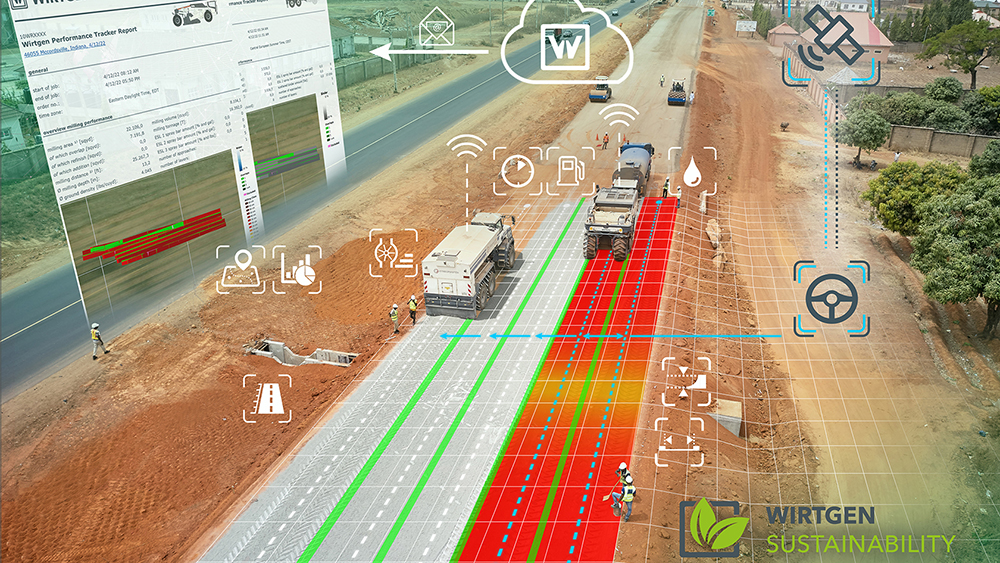

Smart road recycling from Wirtgen

The WR-series machines are also available with the Wirtgen Performance Tracker. The system registers location-specific working parameters to provide a database for site analysis and documentation. For soil stabilisers, data includes working width and depth, area and distance worked and fuel consumption.

The technology is available for the firm’s latest WR series wheeled recycler/stabilisers. The WR-series recyclers have all-wheel drive and have working widths of up to 2.4m and high milling and mixing performances.

Meanwhile, the top-of-the-recycler -range W 380 Cri is a tracked rear loader with a mixing capacity of up to 800tonnes/hour and can be used for both cold in-place recycling (CIR) and full-depth reclamation (FDR) for the rehabilitation of wide roadways.

Booth's S5020 & W40844

Ammann’s compact and productive soil compactor

The ARS 30 and ARS 50 are aimed at road construction firms and rental fleets that need small, durable and powerful machines. The rollers can compact a wide range of materials and have the option of smooth or padfoot drums. The ARS 30 and ARS 50 are powered by Kubota V2403-CR-T diesel engines with EGR+DOC+DPF (without SCR) after-treatment technology and rated at 43.2kW, meeting the Tier 4 Final Stage V emissions requirements.

A combination of an efficient engine, hydrostatic drive system and control deliver economical fuel consumption of 5litres/hour. That efficiency and a large fuel tank of 98litres mean that the rollers need only be fuelled once every three working shifts

The ARS 30 drum has a working width of 1200mm. The single-stage vibratory system and two different frequencies supply compaction power of 37kN and 68kN. The working width of the ARS 50 is 1400mm with a boosted single-stage vibratory system with two frequencies. It provides compaction power of 53kN and 85kN.

A smooth drum is standard on both machines. The ARS 30 has a drum thickness of 15mm, while the ARS 50 drum is 18mm thick. To improve versatility and profitability, the rollers are available with a padfoot (PD) drum (with a smooth shell kit) and a dozer blade.

The drums are designed to be maintenance-free as part of Ammann’s ECOdrop philosophy. The innovative no-rear-axle concept makes the rollers compact and allows a low engine location that improves the centre of gravity for stability.

Also available is the ACEforce system, which enables operators to monitor compaction progress. The Intelligent Compaction system shows the actual kB value on the display, significantly reducing the time required to achieve maximum compaction.

An optional telematics system can help monitor the machine’s position, assist with control and provide other important jobsite information. All the data can be monitored via the web.

Booth S5455

New crushing and screening plant from Powerscreen unveiled

The Gladiator range consists of wheeled, electric-drive, closed-circuit cone crushing and screening plants that are easy to operate and move. The Titan screening plant range operates as a secondary scalper while providing a cost-effective solution in high-volume applications.

Booth S5435