Cummins reports strong performance for 2022

LagoonHull project put on hold

Mini pavers from Vӧgele

New Italian highway project commencing

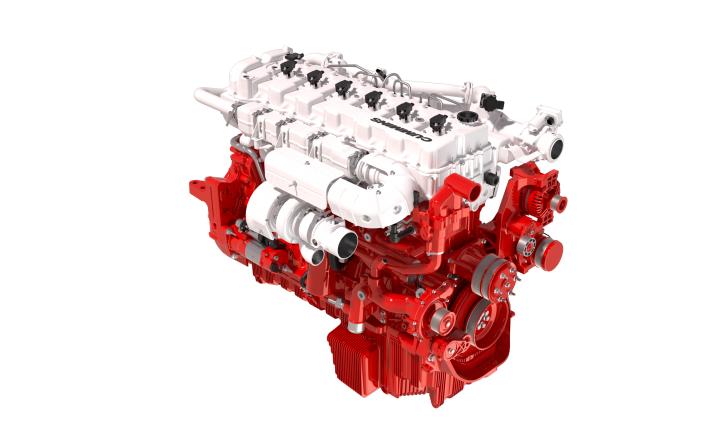

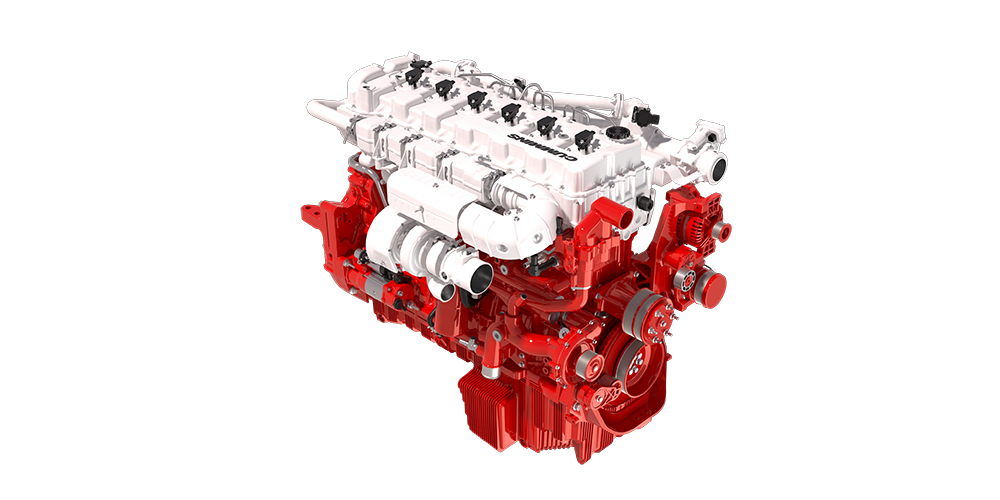

A clean running engine from Cummins

The new platform is designed for the next level of emissions controls and offers a significant increase in power density with a more compact installation envelope. This allows OEMs to increase machine capability and productivity with no impact on running cost.

The fuel-agnostic architecture of the engine from Cummins uses a common base engine with cylinder heads and fuel systems specifically tailored for hydrogen, natural gas, diesel and biofuels including HVO.

The 15litre hydrogen engine will be available with ratings from 300-400kW and a peak torque of 2,600Nm. For applications powered by renewable biogas, this engine will offer slightly lower power ratings with a peak torque of 2,500Nm available. The diesel version will offer a broad power range of 335-485kW, with a 3,200Nm peak torque.

Booth S84615

Novel saw attachments from Simex

The unit suits use for the removal of predefined sections of asphalt for subsequent restoration or for the opening of new road manholes. It can also be used to make sharp cuts for laying fiber optic cables. The clean and burr-free cut produces minimal quantities of waste material and avoids trench deformation, facilitating the filling phase and the quality of the restoration.

Simex now offers for the US market 15 models of wheel saws specifically designed for reduced set-section trenches. The attachments are included into four product ranges: RW, T and D-BLADE for loaders and skid steers, RWE for excavator boom mounting.

Booth W43273

SBM showcasing JAWMAX 400 & giving REMAX 600 update

The JAWMAX 400 on show at the Las Vegas Convention Center is said to feature one of the most advanced diesel-electric drive concepts on the market. A combination of fuel-efficient onboard diesel and performance-tuned generator powers the plant’s materials processing.

SBM’s mobile plant range comprises 12 track-mounted JAWMAX jaw crushers and REMAX impact crushers, capable of 250 – 800tph production. The plant range shares the same innovative drive concept, with fewer hydraulics ensuring less risk of failure, lower maintenance and parts inventory costs, and thus higher availability, says SBM. Overall savings from running the plants can, says the OEM, be 40% to 75%.

All SBM plants provide intelligent integrated ‘Crush Control’ controls that noticeably relieve the operator in set-up and operation. The company stresses that even inexperienced machine operators can safely operate and access the full performance of the JAWMAX and REMAX models, which can be equipped with numerous pre-screening and post-screening options.

At CONEXPO/CON-AGG 2023, SBM will also update showground attendees about the brand-new REMAX 600. Based on the SBM hybrid concept, the new 600tph impact crusher will soon pave the way for "autonomous crushing", says the manufacturer. Extensive sensor technology, including cameras, records and evaluates the feed material as well as intermediate and end products. In real-time, those values reach centralised digital labs at SBM, where they are further analysed. Necessary adjustments are then made on the ‘digital twin’ of the working machine and re-transmitted directly to the REMAX 600 in the field. The REMAX 600 – known as ‘Crusher 4.0- - developed together with the University of Leoben was presented at the recent bauma 2022 Munich exhibition. Large-scale field tests are currently being carried out at selected partner sites.

SBM is planning a sustainable expansion of its sales and service activities in North and South America as well as in the Anglo-Pacific region. So far, the company is represented in Canada with its own spare parts centre and two supra-regional dealers (AMACO Equipment and ProTrack Equipment). SBM is particularly focused on the US market and is there in all relevant industry segments, from raw materials to the construction industry to qualified recycling. During CONEXPO/CON-AGG 2023, SBM will be presenting new trade partners and is keen to receive enquiries from interested companies.

SBM Mineral Processing will be at Silver Lot, Booth: S5600

Deadline soon for AfPA abstract submissions

SWARCO milestone in Reading

FM Conway wins UK contract with National Highways

Improving compact equipment efficiency with machine control

More Norway wooden bridges to open

Doka completes takeover of AT-PAC

Australian road surveying plan

Win a roller model with Ammann

Caterpillar is gearing up for CONEXPO-CON/AGG 2023

Loan for new road in Honduras