Concrete technology addition for Wacker Neuson

Expanded and branded

Stonehenge Bypass contract awarded to consortium

UK’s road safety statistics

CIFA’s latest concrete pump

Concrete paving in Iceland

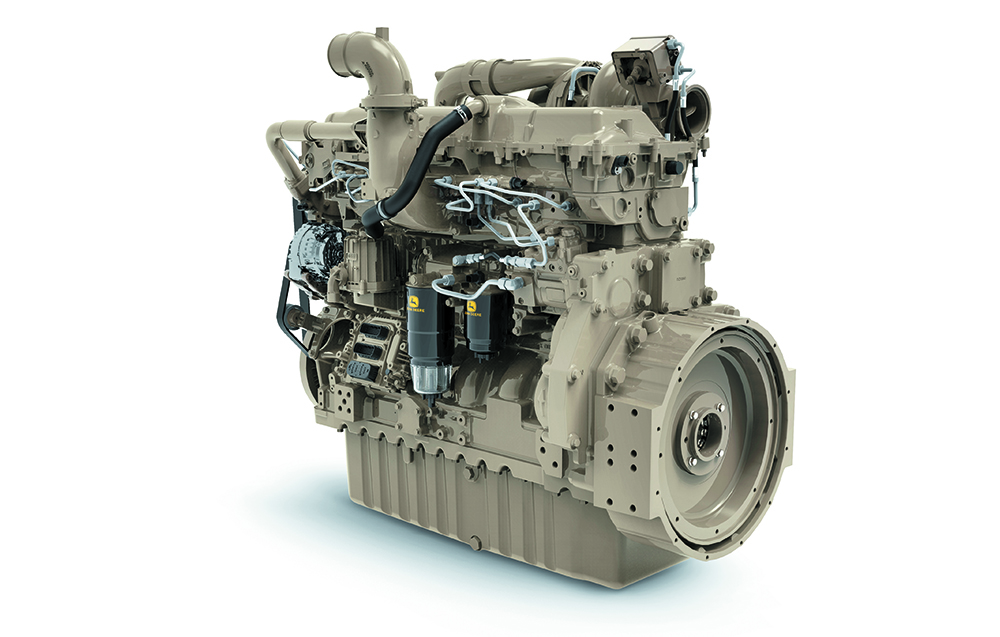

Future-Forward Power Solutions from John Deere

Sweco Nederland - 3D modeling software streamlines road design projects

Efficient road maintenance with Simex

Simex at Bauma Munich from 24 to 30 October, Hall C5, Booth 325.

Bauma Munich – the most anticipated trade fair event in terms of strategic importance, turnout, new product launches and media impact for the earthmoving sector – has always been an opportunity for Simex to show to its partners and users its technical quality. The ability to innovate and do research, combining the new models in the range with new technological concepts, it’s the Simex way to outline the paths to be followed in the future.

bauma China 2022 construction machinery exhibition cancelled

South Sudan road link project

BIM for US bridge building

Volvo CE moves on carbon reduction

US bridge deal to be handled by Tutor Perini

High-accuracy receiver

A new Malaysia-Indonesia link

Efficient binder and chipsealing machine innovation

According to Secmair, the machine can be adapted to a range of jobsites and for duties such as surface dressing, tack coating before the hot asphalt mix, coating and priming and localised treatments. The chip application rate is optimised to ensure that there is no waste and the system is said to ensure accuracy and quality during application, providing the same level of quality as for conventional surface dressing equipment.

The machine is controlled by a single operator who sits in the cab, with high visibility of the worksite and optimised safety. A camera at the front of the vehicle provides visibility of the working area.

The CHIPSEALER CT is equipped with a proven conveyor belt discharge system while the telescopic spraybar allows maximum spreading widths of up to 4.4m. Tank capacities can range from 4,000-9,000litres, depending on the customer requirements.

The cab features joystick controls with a screen showing all key parameters, while the unit has automatically controlled application. Other key features include an exclusive valve block to manage the binder, precise dosing and transversal distribution. The controls ensure that the unit will apply the correct quantities of materials. Other important features include thermal insulation and heating, a system that minimise fuel consumption and an efficient purging control that is 100% automatic and ensures that there is no waste left on the ground.

The CHIPSEALER CT can be equipped with the firm’s new pilot system, which allows a more precise patch application without overconsumption of materials. For patching, the DUOSPRAY option is said to ensure optimal dosage on all the application width, while enriching jets ensure that the chips adhere to the sides of the area being repaired.

Asphalt milling, paving & compaction

Asphalt milling, paving & compaction

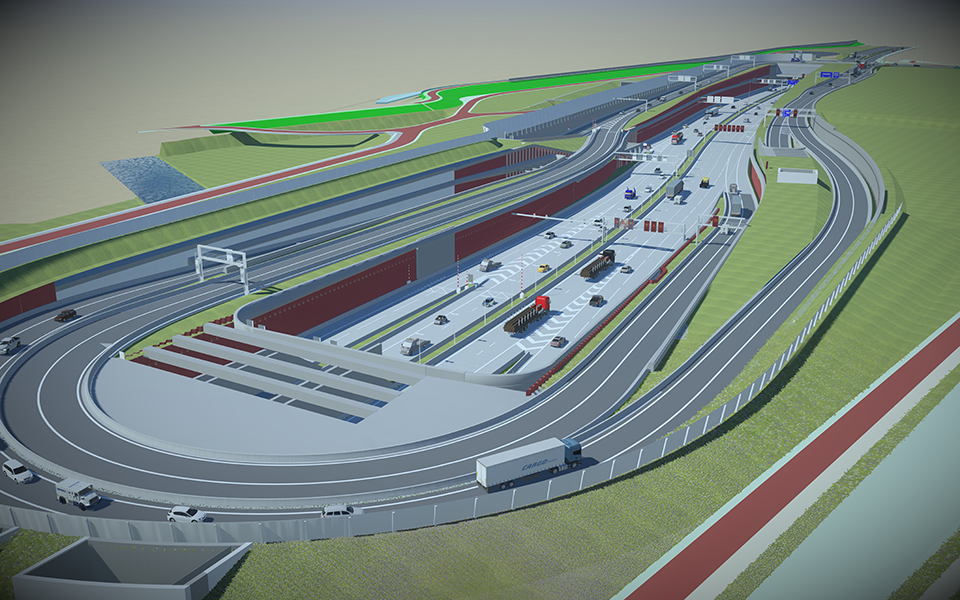

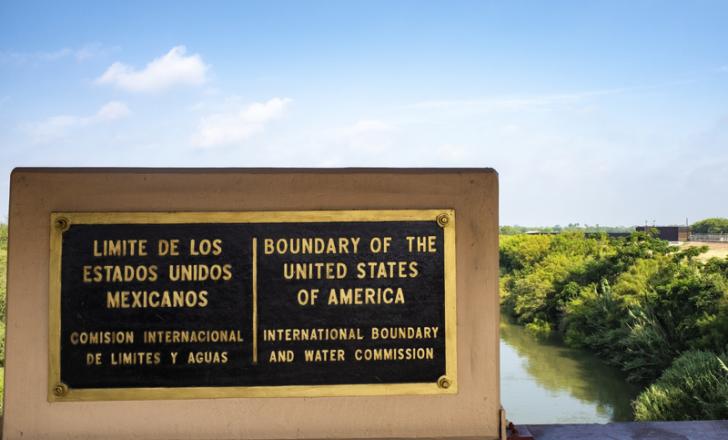

US-Mexico border crossing upgrade planned

Changes possible for Lake Mjøsa Bridge

DUI dangers in the US