New Guatamala City bridge package awarded

Shell and CRH in decarbonisation agreement

Russia ploughs ahead with road expansion

Mobile mapping tool

Vietnam’s Mekong Delta development programme

Wirtgen’s new compact milling machines

All three models offer high productivity and maximum cutting depths of 330mm, with the firm’s sophisticated digital assistance systems; Mill Assist, Wirtgen Performance Tracker (WPT) and Level Pro Active levelling.

In automatic mode, Mill Assist optimises milling performance and operating costs. This increases milling performance while reducing diesel, water, pick consumption and CO₂ emissions. This controls engine speed and provides a wide range of usable milling drum speeds for a range of applications. The low-speed range cuts fuel consumption and pick wear. The upper speed range delivers an optimal milling pattern, even with high performance rates. The operator can also select one of three operating strategies for each milling job: ECO, performance-optimised or milling pattern quality.

Compact dimensions and optimised machine weight make the machines easy to transport. High performance means that the machines can handle a range of applications including surface layer rehabilitation and pavement removal. The machines have the proven LEVEL PRO ACTIVE system offered previously on the large machines, offering automatic features such as automatic lifting for driving over manhole covers.

In addition, these compact mills can also be fitted with the firm’s newly developed operator cab, which is said to offer good visibility of the working area and sophisticated, ergonomic controls.

Recycling

Recycling

Dynapac's remote control paver option

Small, yet powerful, the Dynapac F1250CS suits use where high-quality paving is required with widths of 0.5-3.5m. The remote unit allows users to position themselves where they want.

The F1250CS has a high-end screed available with gas and electric heating. The V2400 has the same quality and performance as its larger stablemates and has an extension box for greater widths. As an added benefit, the Dynapac F1250CS can pave below zero, thus increasing refurbishment job efficiency, since the paver can drive out of the milling cut, allowing the screed to pave a smooth finish.

Multiple adjustments such as for angle of attack and the deep bottom plates allow high pre-compaction and a smooth surface, even with thick layers. The quick coupling means setup and operation are easy to use.

The RC360 remote unit allows operators to control the paver from a point that offers the lowest asphalt fumes while providing maximum visibility and results. The remote comes with a case and charging devices with a mechanical connector for external supply.

Ensuring safety during remote operations is important so when the operator is more than 10m from the paver, it stops automatically. The paver also stops automatically when the remote is tilted higher than a 45° angle.

The F1250C comes with a 54kW Deutz engine in either Tier 3/Stage III or Tier 4/Stage V versions to local emissions requirements.

Asphalt milling, paving & compaction

Asphalt milling, paving & compaction

Big on power, Caterpillar’s 980 loader

The 980 XE, which like all Caterpillar machines is being shown by the company’s Germany-based dealer Zeppelin, meets emission standards without interrupting operation.

It features a continuously variable transmission delivering increased fuel efficiencies up to 35% compared to the M series model. It also has expanded technology platform to increase machine performance.

Meanwhile, for the operator, comfort is paramount. The seat-mounted electro-hydraulic joystick steering system provides precision control and dramatically reduces arm fatigue, resulting in excellent comfort and accuracy. The next generation of ride control works as a shock absorber, improving ride quality over rough terrain.

Outside the cab, inclined steps and convenient grab handles ease accessibility. Extended windows enhance visibility, while convex and spot mirrors extend the driver’s view on the sides and rear.

Earthmoving & soil compaction

Earthmoving & soil compaction

Reduced-temperature asphalt

Amey Group being sold by Ferrovial

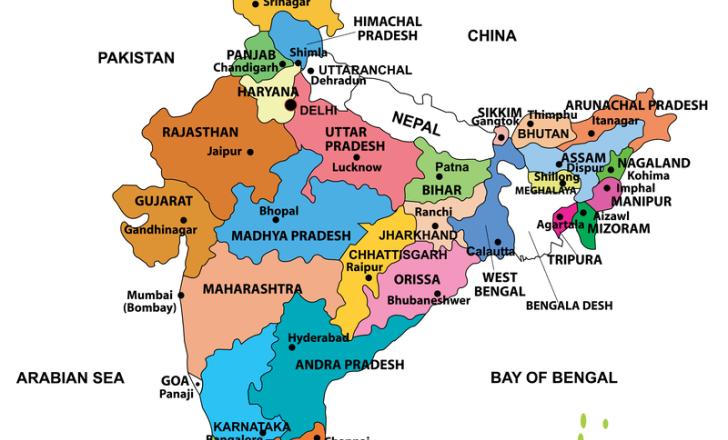

Indian expressway secures funding

Romania’s major road development plans

Sophisticated tooth loss detection system

Signals emitted by the GET sensors are transmitted via antennas and processed by an electronic control unit. A tablet in the machine cabin displays the GET’s live status and alerts the operator in the event of a detachment by visual and acoustic warnings.

The system is the product of a five-year development programme and MTG says that it will help reduce damage to crushers and minimise downtime, delivering major cost savings for operators. Because the system is simple, there is no need for additional training to use it.

Being able to stop the excavator quickly when a tool detaches addresses the risk from these hard components ending up in the crusher, which would otherwise cause extensive and costly damage as well as halting processing operations.

MTG says that the system is available for use on excavators weighing 250tonnes or more in Australia, Europe or the US, but will be available in more markets in due course.

Komatsu’s electric micro

Funding boost for Colombia’s rural roads

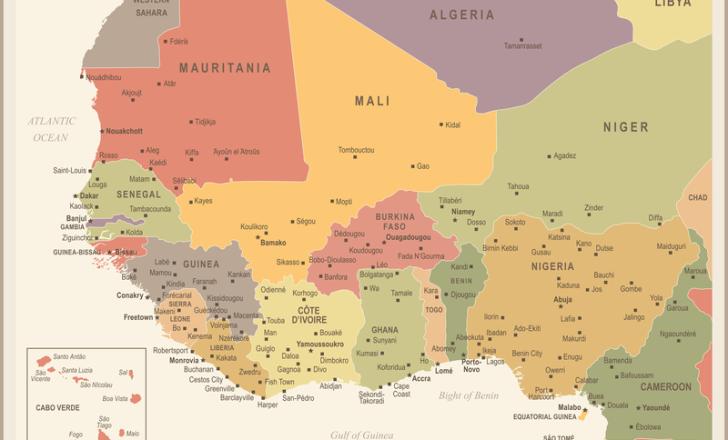

Funding secured for road works in Côte d'Ivoire and Senegal

Liebherr’s new mixing plant generation