Profit boost for Rolls-Royce Power Systems

Efficient cold mixing plant developed by Wirtgen

The machine features innovative double trough technology that the firm says doubles the speed of the production of mix from various different construction materials. The system allows precise, reliable and automatic addition of large amounts of hydraulic binding agents. As a result, the mix production process achieves high efficiency and quality.

The KMA 240(i) can process a variety of non-cohesive base materials. The double trough system has automatic self-calibration and precision weighing, allowing the addition of binding agents during the continuous mixing process. Depending on requirements, either small or large amounts of binding agents can be added. Milled RAP or other granular material from old road surface layers and other materials from RC processing can be used as environmentally friendly construction materials.

This plant can also produce mixes for cement-stabilised base layers (CTB) and roller compacted concrete (RCC) at rates of up to 240tonnes/hour. These construction materials are integrated in the road construction cycle as high-quality mixes. They can be used for applications ranging from motorway, road and path construction to the construction of vehicle parking areas.

The 100% recycling rate enables considerable CO2 reductions and energy savings, while simultaneously minimising project costs and working time. The plant is mounted on a low-loader semi-trailer, allowing it to be transported easily and also has its own engine.

High performing asphalt pavers launched by Vӧgele

Flexible, modular systems are featured that meet needs for process automation and sustainability, as well as user-friendliness and economy.

User requirements have been a key focus during the development of these machines according to the firm. For the paving crew, this allows simple machine handling, maximum operating convenience and safety on the job site.

Reduced setup times, improved logistics and greater machine availability are said to deliver ensure fuel economy and reduce material wastage, helping address increasing fuel and materials costs. New automation and control technology provides operator assistance and has been optimised to prevent errors and to increase efficiency and paving quality according to Vӧgele.

Reducing the noise emissions and fuel consumption of Dash 5 pavers while maintaining the same performance helps meet sustainability targets for contractors, while also lowering fuel costs and CO₂ emissions.

China is improving the road network

Accurate machine control with Trimble

The system can actually steer the machine, with the operator only having to select forward or reverse. In dozer operation, high efficiency is claimed as the package can make significant reductions in fuel consumption, while delivering high productivity.

For soil compaction duties the machine will steer accurately into position, ensuring that each pass has an optimum overlap. Using the package also allows an optimum number of passes to be carried out, ensuring target values are met and without risking over compaction.

Topcon ties systems together

“Now that the machine guidance and control technology is pretty much standard, we see a lot more adoption,” said John Downey, senior director sales, EMEA at Topcon Europe Positioning.

The company’s systems can show which machine is productive and whether a job a job is on schedule – for example, where all the haul trucks are lined up, or where more excavators are needed. “Now we can see this digitally. This is something we didn’t know in the past,” said Downey.

“Now you can get a report every hour, every day, every week, from every part of a project. Every machine becomes a sensor on site. You can see if someone is getting behind schedule.”

“Now we want to connect all the machines and start bringing the data and get real-time information from the machines, so we can weigh each bucket from the excavator, for example.

“Margins are small these days. Everyone wants to see where their money is going.”

Kleemann GmbH Company Profile

Kleemann GmbH has been developing and building innovative crushing and screening plants for rock processing for roughly 100 years and is a member of the internationally active Wirtgen Group.

As part of the Wirtgen Group, Kleemann is ideally positioned to offer on-site service and assistance worldwide. This enables the best possible customer support and, as a result, outstanding performance and availability of the plants over the long term.

Kleemann machines are in operation worldwide: Cost-effective. Sustainable. Intuitive.

Kleemann machines are in operation worldwide: Cost-effective. Sustainable. Intuitive.

Kleemann crushing and screening plants excel thanks to their high performance, low consumption and well-engineered machine concept. The mobile plants are used all over the world: for natural stone processing in quarries or in road and tunnel construction, in recycling to process construction waste or in mining plants for raw material processing. As all-rounders, the EVO Line plants stand out with their versatility, easy transport and short set-up times. They are especially suitable for the contractor sector.

The PRO Line plants distinguish themselves with their extremely robust construction, their ability to handle large feed sizes and their very high performance. They demonstrate their strengths particularly in quarry applications.

All machines offer simple operation, high cost-effectiveness and efficient, sustainable drive concepts for the respective application.

All machines offer simple operation, high cost-effectiveness and efficient, sustainable drive concepts for the respective application.

At this year’s Bauma show, new machines from the EVO and PRO lines as well as innovative technologies and environmentally friendly solutions will be presented.

Booth FS.1011

KLEEMANN GmbH

Manfred-Wörner-Straße 130

73037 Göppingen | Deutschland

T: +49 7161 206 0

[email protected]

www.kleemann.info

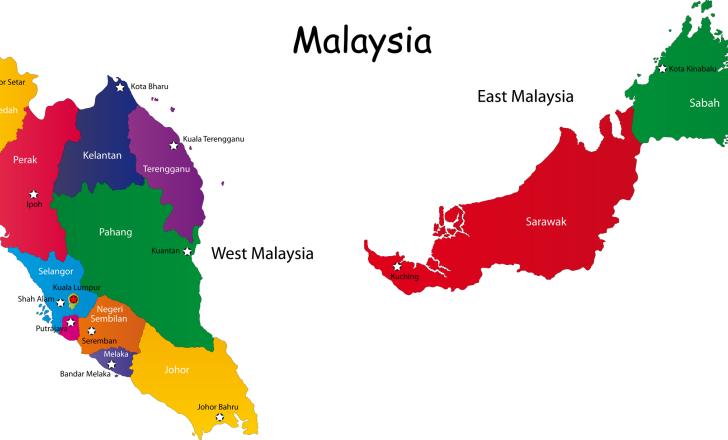

Malaysian highway works planned

Compaction machine innovations available

On the fly with Pilosio’s Flydeck

In addition, using the Flyrail rail to set up the Flydeck surface allows the work to become easy and fully safe. With this solution, it is possible to create wraparounds for columns, piles, dosserets and any other element.

The Flydeck surface must be anchored to the back side of the deck, such as roads, highways or railways, without blocking traffic. Also, there are no width, length or capacity limitations since it is a modular system and can be combined with beams and scaffolding steel planks of any brand, model, shape and size.

The system consists of 25cm or 45cm aluminium or steel lattice girders connected by patented pins and spring pins. The girders are installed using the Flydeck rail that guarantees, in addition to high safety, a significant reduction in assembly and disassembly time for each stage. Time savings can by about one-third compared to traditional systems and about one-half compared to multi-directional scaffolding systems.

The Flydeck system can be assembled by accessing it from an abutment or a column without using the by-bridge or negative surface platforms. This solution greatly reduces the assembly and disassembly time of suspended structures by halving their cost and greatly reduces costs in case of rental, halving the storage overall dimensions and costs for handling and transportation.

In addition, 25cm aluminium or steel girders offer more maneuverability than the 45cm ones. Joining the beams is very fast and safe thanks to spring pins that simplify assembly/disassembly and ensure perfect co-planarity of the work surface.

CIFA’s rugged new concrete pump

The K50L pump is a versatile, heavy-duty machine and suits duties on large construction sites, while being tough and easy to maintain. The K56L is available with a choice of pumping units to suit customer needs.

A key feature is the electronic management system, called Smartronic. This is said to make operations safe and easy and offers smart management of the various functions. The Steeltech K50L has a boom that features the firm’s proven RZ configuration, allowing high vertical extension without complex placing operations. The new upperstructure and external piping is said to make maintenance easier, as well as being more compact.

The CIFA Vista telemetry system is available as an option and allows users to manage and monitor the equipment fleet. The system can be used to manage maintenance intervals, store performance parameters and report any fault or error message.

The X-type stabiliser system has been simplified and improved. The chassis of the K50L is said to offer easy access for maintenance and the structure is said to provide good weight distribution, meeting axle load requirements.

Texas road improvement works for Webber

Cummins reports strong Q2 results for 2022

Edeva makes Actibump available globally

TRL and Experion develop Indian joint venture

IRF 2022 Annual Conference to be hosted in Marrakech

Lower asphalt plant emissions

While reclaimed asphalt can be added to the production process with reliable cold and hot recycling technologies, this does can result in higher emissions of total carbon (Ctot, volatile organic compounds (VOC)). When reclaimed asphalt is heated, part of the Ctot concentrations evaporate from the bitumen contained in the recycling material. These have a higher greenhouse potential than CO2 and are hazardous to health in higher concentrations.

The REVOC system is a solution for reducing emissions from asphalt production by making the existing mixing plants more efficient. The option of adding up to 60% recycling material can reduce emissions to comply with legal limits. At the same time, the higher recycling content also increases cost effectiveness of existing plants.

The REVOC system extracts the emissions where they are generated, primarily from the mixer. The generated vapours have increased Ctot concentrations and are moved to the REVOC system for thermal processing. This step uses the energy generated for drying and heating the virgin mineral and is therefore extremely energy-efficient. Most importantly, however, the technology can reduce Ctot emissions by up to 50%.

Recycling

Recycling

New highway works are planned for Thailand

Romanian road deals