In addition, using the Flyrail rail to set up the Flydeck surface allows the work to become easy and fully safe. With this solution, it is possible to create wraparounds for columns, piles, dosserets and any other element.

The Flydeck surface must be anchored to the back side of the deck, such as roads, highways or railways, without blocking traffic. Also, there are no width, length or capacity limitations since it is a modular system and can be combined with beams and scaffolding steel planks of any brand, model, shape and size.

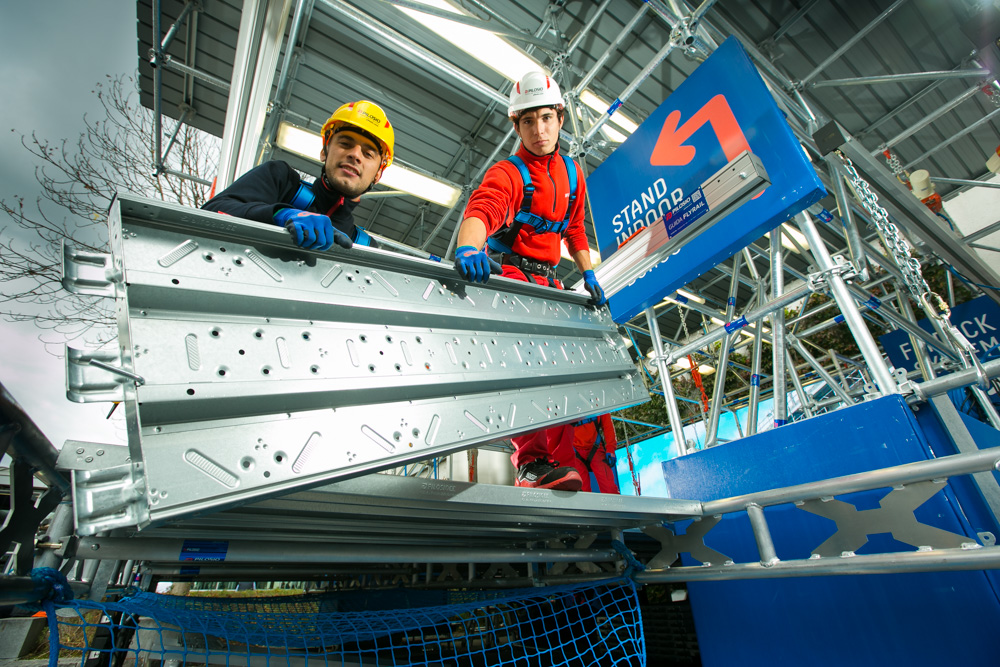

The system consists of 25cm or 45cm aluminium or steel lattice girders connected by patented pins and spring pins. The girders are installed using the Flydeck rail that guarantees, in addition to high safety, a significant reduction in assembly and disassembly time for each stage. Time savings can by about one-third compared to traditional systems and about one-half compared to multi-directional scaffolding systems.

The Flydeck system can be assembled by accessing it from an abutment or a column without using the by-bridge or negative surface platforms. This solution greatly reduces the assembly and disassembly time of suspended structures by halving their cost and greatly reduces costs in case of rental, halving the storage overall dimensions and costs for handling and transportation.

In addition, 25cm aluminium or steel girders offer more maneuverability than the 45cm ones. Joining the beams is very fast and safe thanks to spring pins that simplify assembly/disassembly and ensure perfect co-planarity of the work surface.