Work on the new Formula 1 racing circuit in Abu Dhabi is progressing at high speed. Over 6,000 construction personnel are working in the United Arab Emirates (UAE) to complete the new high-speed circuit and its infrastructure. German contractor Bickhardt-Bau is carrying out the paving work, using a fleet of new Vögele pavers and Hamm compaction rollers.

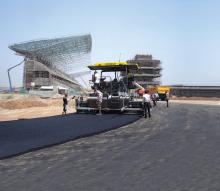

Paving work for the new UAE racetrack has been carried out hot to hot, with two SUPER 1900-2 pavers working together on the straights

Work on the new Formula 1 racing circuit in Abu Dhabi is progressing at high speed. Over 6,000 construction personnel are working in the United Arab Emirates (UAE) to complete the new high-speed circuit and its infrastructure. German contractor 3357 Bickhardt Bau is carrying out the paving work, using a fleet of new 1194 Vögele pavers and 228 Hamm compaction rollers.

The contract has been challenging with 5.5km of paving for the race track, pit lanes, paddocks and emergency roads. As this is a race track and the vehicles using it reach incredibly high speeds, build quality has had to be to the highest possible standards in terms of factors such as structural strength, smoothness and skid resistance. In all, the project in Abu Dhabi has required laying 950,000tonnes of crushed stone for the base course and surfacing 750,000m² with 210,000tonnes of asphalt.

The contractor is using two high-performance SUPER 1900-2 pavers equipped with AB600-2TP2 screeds. The high compaction screeds are proving valuable for laying the different courses to the high standards required. For the base and binder courses, the high compaction exerted by the tamper and twin pressure bars on these screeds has been particularly important. In this configuration, the pavers have delivered pre-compaction of 92% and more.

Contractor Bickhardt Bau met the high requirements in terms of accuracy using the sophisticated Niveltronic Plus control system fitted to the Vögele pavers as this package provides automated grade and slope control. On the racetrack, 20m wide, base and binder courses were paved on most sections and these were installed in four strips of 5m each. When paving the 80mm base course for the straights and wide bends, Bickhardt Bau installed a tensioned wire on the outer side of the first strip. For the adjacent strips, the firm used the slope sensor combined with a multiple sonic sensor tracing the previously paved strip. On the tight bends, a tensioned wire traced by the multiple sonic sensor, was used for all four strips.

The composition of the mix is key to racetrack construction: on a crushed-stone base, 50cm thick and spread by graders, 80mm asphalt base (0/19) was paved. The binder course, laid in a thickness of 40mm, is aggregate with a maximum grain size of 14mm bonded with polymer modified bitumen. For the surface course, a special mix for racing circuits was used, based on aggregate with a grain size distribution of (0/11).

The contract has been challenging with 5.5km of paving for the race track, pit lanes, paddocks and emergency roads. As this is a race track and the vehicles using it reach incredibly high speeds, build quality has had to be to the highest possible standards in terms of factors such as structural strength, smoothness and skid resistance. In all, the project in Abu Dhabi has required laying 950,000tonnes of crushed stone for the base course and surfacing 750,000m² with 210,000tonnes of asphalt.

The contractor is using two high-performance SUPER 1900-2 pavers equipped with AB600-2TP2 screeds. The high compaction screeds are proving valuable for laying the different courses to the high standards required. For the base and binder courses, the high compaction exerted by the tamper and twin pressure bars on these screeds has been particularly important. In this configuration, the pavers have delivered pre-compaction of 92% and more.

Contractor Bickhardt Bau met the high requirements in terms of accuracy using the sophisticated Niveltronic Plus control system fitted to the Vögele pavers as this package provides automated grade and slope control. On the racetrack, 20m wide, base and binder courses were paved on most sections and these were installed in four strips of 5m each. When paving the 80mm base course for the straights and wide bends, Bickhardt Bau installed a tensioned wire on the outer side of the first strip. For the adjacent strips, the firm used the slope sensor combined with a multiple sonic sensor tracing the previously paved strip. On the tight bends, a tensioned wire traced by the multiple sonic sensor, was used for all four strips.

The composition of the mix is key to racetrack construction: on a crushed-stone base, 50cm thick and spread by graders, 80mm asphalt base (0/19) was paved. The binder course, laid in a thickness of 40mm, is aggregate with a maximum grain size of 14mm bonded with polymer modified bitumen. For the surface course, a special mix for racing circuits was used, based on aggregate with a grain size distribution of (0/11).