The first tunnels are being excavated for the huge bypass tunnel in Sweden’s capital Stockholm – Adrian Greeman writes. After years of preparation and design, blasting and rock moving for Sweden's largest infrastructure project began south of the city this year. It sets in train a decade-long project that will create a new half-ring dual three-lane motorway for the city, 20km long. With most of it deep underground, it will also be one of Europe's largest ever road tunnels. The scheme is aimed at transformin

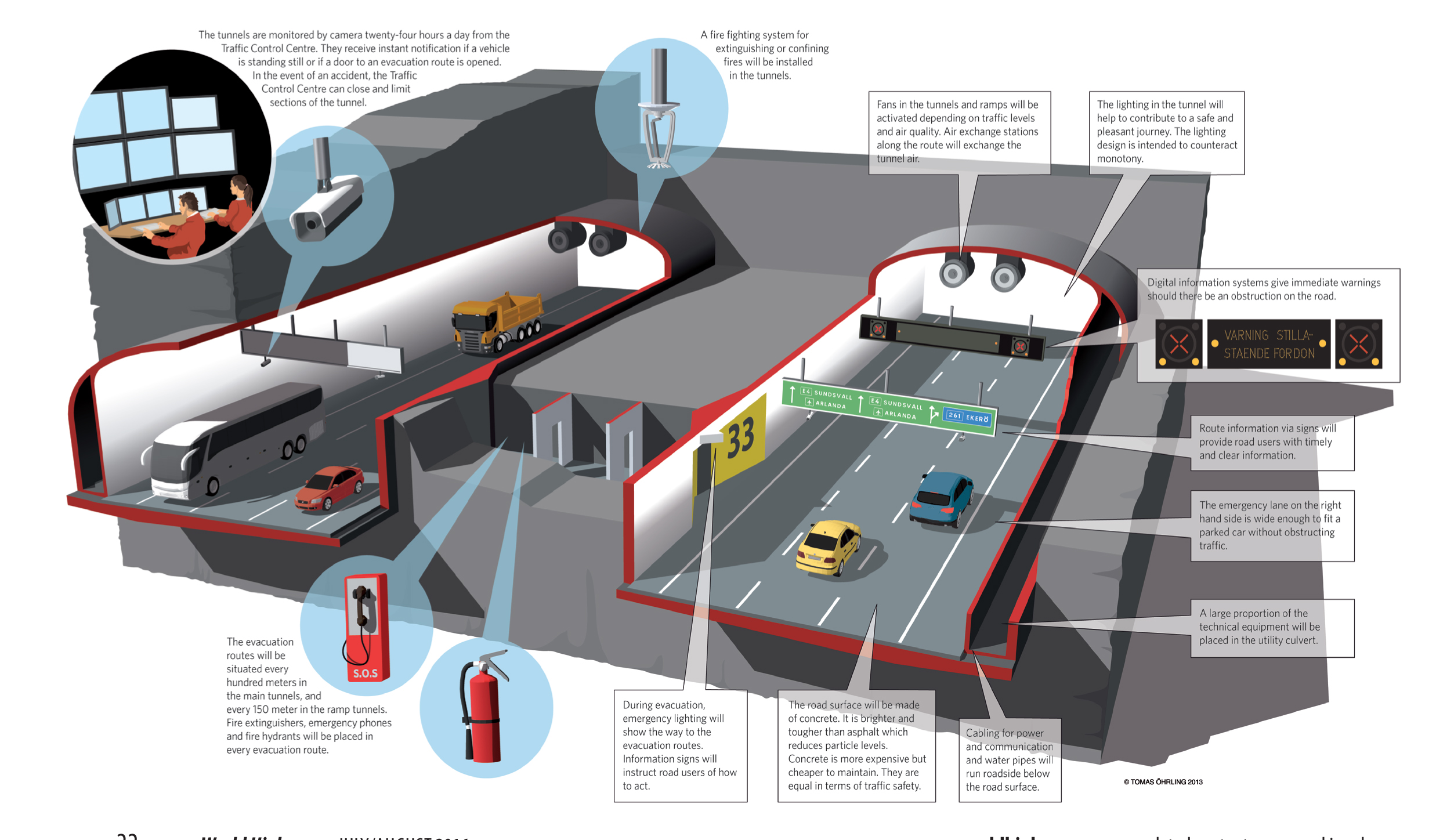

The new tunnel system features a high degree of safety systems

The first tunnels are being excavated for the huge bypass tunnel in Sweden’s capital Stockholm – Adrian Greeman writes

After years of preparation and design, blasting and rock moving for Sweden's largest infrastructure project began south of the city this year. It sets in train a decade-long project that will create a new half-ring dual three-lane motorway for the city, 20km long. With most of it deep underground, it will also be one of Europe's largest ever road tunnels. The scheme is aimed at transforming a growing congestion problem for Sweden's capital which can be a highly frustrating city for residents trying to move around, and especially those in the south wanting to work in the north or, vice versa. "In medieval times the water was a means of movement but nowadays it is an obstacle," said Jesper Niland, technical manager for the project client, the Swedish Road Authority.

"At times it can seem like there are almost two cities and getting from one to the other is a major difficulty" added overall project director, Johan Brantmark. After just a day or two in the city the snarl-ups are obvious with traffic jams almost constant for extended rush hours. It can sometimes take hours to get home by car.

The impact of the congestion is mainly within Stockholm itself, affecting the 2.2 million or so people living in the Stockholm metropolitan area. There is passing traffic heading to the relatively unpopulated north but that is currently fairly limited and some 95% of the traffic is local. "It either starts or finishes in the city or both," said Brantmark.

The introduction of a congestion charge some years ago lowered traffic volumes, but not sufficiently to fully address the congestion problem. Rail links that could help are also overextended, although a new "City Banan" central train line will open next year. But though the new line doubles the current twin-track line capacity of the central station, it will only partially meet demand.

The problem arises from the geography of the city, which sits between the edge of the Baltic archipelago and several large inland lakes and further associated islands. It is a beautiful setting, and makes Stockholm one contender for the perhaps overworked "Venice of the North" designation, with all its waterways. But it also means the city is split in two by a large channel.

"And there are only three links across," said Brantmark. One of these is around the central island of the old city, where "the Sluice" separates the lake and the Baltic, and another on a bridge over the lake. "But the only high-capacity crossing is the E4 route on the west side."

Not only does this restrict traffic, it leaves the transport network vulnerable, he said. "If a bridge is damaged, and we have had some incidents of barge collisions or if repairs are needed, the impact is significant."

The proposed solution is a new motorway link which will essentially reroute the E4 motorway west of the capital, running south to north, and joining to a new northern link running eastwards across the city. Together with an eventual southern section this will make a half ring outer motorway. The eastern half is not needed as that would put it in the Baltic Sea.

The old E4 will remain but redesignated as a local road and with reduced traffic loads. "These are currently about 110,000 vehicles/day," said Brantmark. The new route is expected to see traffic volumes increase up to 140,000 vehicles/day, some 10 years after it opens in 2026.

But passing the road westwards has been fraught with problems, and some political objections, which for a while suspended the project while its go-ahead was debated. Most of these issues are environmental; contesting the overall existence of the road itself and its location.

For many "greens" the new road, which began significant design work in 2011, was seen as encouraging and perhaps stimulating traffic growth. That would be causing unacceptable emissions at a time of global warming; investment should instead go on new metros.

"A new government in 2014 therefore made a reassessment of the project but eventually decided it should go ahead," said Brantmark, "not least because the city is quite rapidly growing."

A second issue is the potential damage to some relatively pristine areas the route must cross, including several lake waterways and a large island, Lovön, which includes a royal palace and is mostly parkland over the rest of its area.

"The result is that, as the decades have gone by, an original proposed scheme mostly above ground has been more and more put underground," said Niland. The central part of the scheme will now be a single underground section 16.5km long with a further 1.8km tunnel section to the north after a junction with an existing motorway. There are short at-grade sections at the end too.

Not only is the scheme very long for an urban tunnel but it will also drop fairly deep, as much as 65m below sea level, to ensure that it can pass beneath the water channels and any cracks and fissures there might be in Sweden's very hard rock.

And it will be huge; a twin bore tunnel for a full motorway of three lanes in each direction and associated safety shoulders. The total width of the two rock bores is 16m. Along with the main tunnel there must also be a large number of approach and leaving ramps for various junctions, including one at each end linking into the existing E4; one at the north end between the two tunnels sections where the E18 route passes east to west; and two intermediate junctions, one on the island of Lovön and another in an urban area north of that. As these junctions will also be partly underground, an additional 14km of ramp tunnel is needed, as well as further work for seven access tunnels.

The junctions are significant projects in themselves, particularly the Häggvik junction in the north and the Kungens Kurva, where the road ties into the existing motorway at the southern end, each having multi-lane sections and major bridge and ramp structures above ground as well as below.

The challenges in carrying through these projects are not simply the design of the structures themselves and their construction but also the need to keep the existing traffic flowing freely, or at least as freely as it can be said to flow at present.

"Safety, and security are the top watchwords for the project," explained Brantmark, "and that includes avoiding any disruption of the circulation or making the network any more vulnerable. Keeping the vehicle users free from extra stress is important."

The junction contracts, currently being let after a long international tendering period, are therefore to be done on a design-build principle. The aim is to encourage innovation from the contractors, particularly with temporary works and traffic management.

"The tunnel works are done differently. As with all tunnels we follow the principle that the ground conditions can be variable and are therefore the responsibility of the client, more or less in line with the British code of practice which evolved after the Heathrow tunnel collapse."

Design will be done by the client, with the contractor responsible for implementation. Extensive geotechnical investigation and coring has been done to assess rock quality.

Sweden has long experience in hard rock tunnelling and this obviously informs the design of the project, which will be carried out by traditional drill and blast methods. The rock is primarily a granitic gneiss, commonplace throughout the ancient rocks of the Baltic Shield.

In Sweden the basic excavation technique always includes extensive pre-grouting of the rock on most projects, ensuring that cracks and fissures are sealed and the rock is "tight" to fairly severe limits of water leakage.

That is especially important on this route where there is a reasonable level of fracturing and cracks in the rock said Niland, not least from the lake bed sections above.

Though it takes longer to do things this way, "…it is usually quite successful and means the requirements for lining the rock tunnel against water ingress are reduced," said Brandt, who holds a doctorate in rock mechanics himself.

A major issue to come will be blasting vibrations particularly in the southern sector and further north where the tunnels pass underneath urban areas and buildings. Rock transmits vibrations rather too well. Some mitigation measures are already underway including the mass double glazing of a housing estate near to one of the sites for a junction.

Not all the tunnelling will be in hard rock however, and there are sections particularly, as ramps approach the surface, which most cope with clays and glacial tills laid down during the Ice Age.

The tunnel itself has some modern features, most notably an inner envelope set around half a metre in from the rock excavation walls. "This is to make an inner seal and also to set a good shape for the tunnel interior," explained Niland. It is made using a flexible membrane supported on rock bolts standing out from the bare rock walls and then coated with layers of shotcrete to form a rigid shell.

"The older method was a drainage mat and shotcrete on the rock but this offers better control of water leaks," said Niland.

He explained that the space outside the shell is inaccessible. But for later maintenance a newly developed semi-robotic scanner is being modified from one used at present for the London Underground, to pick up any changes in the rock profile over the years.

Sweden famously pays a lot of attention to road safety – the Volvo car is known for it, and the design of the tunnel will reflect that. The major feature is a cross-passage system linking the two sides allowing for evacuation in the event of a fire or crash and for the access of emergency services from vehicles in the opposite carriageway. The relatively small passages are sealed with pressure doors and contain communication links, firefighting equipment and water hydrant points.

"The principle is 'self-evacuation' through short but frequent tunnels," said Niland. The cross-passages will be made every 100m which is much above the 300m level common in many modern tunnel systems such as the Gotthard high speed, and even more above the European minimum of 500m.

The cross-passage system is part of a tunnel fire system that includes heat and smoke detectors and emergency radio communications network.

Ventilation is another important aspect of the tunnel safety both in emergencies and during normal operation. With an anticipated 140,000 vehicles/day, keeping the air clean and safe presents a significant challenge.

Surprisingly the design has gone for a longitudinal system using ceiling mounted jet-flow fans, where the fan output drags the rest of the tunnel air along. For very long tunnels over 4km it is more normal to provide a system using under road or ceiling ducts, drawing in or pushing air out through slots.

Such tranverse systems need more structure however and more complex air flow and control.

"We are able to use a longitudinal system because the tunnel has been broken into sections," said Niland. "Every 4km there is an air exchange station which draws fresh air from the surface through a vent and discharges stale air through another. We had a lot of discussion on this and design and modelling studies."

The 8m diameter intake and out-take vents are spaced 100m apart and will require some major raise boring work to reach the surface from the 65m depth of the tunnels. They are fitted with big tranverse fans, some 48 in all, complementing 250 jet fans in the tunnels. Additional smoke extraction-only vents to the surface will be provided near the tunnel entrances.

Taken together, the system and associated air quality, smoke and air temperature detectors, will allow a fairly high level of control over different sections of the tunnel and also a means to isolate smoke and heat from fires.

A water sprinkler system will also come into play in the event of fires, says Brandt.

Another safety aspect for the tunnel will be an architectural interior finish and variated lighting to change the appearance of the tunnel for drivers as they pass through. However, 16km is a long drive underground and ways to keep drivers alert are needed.

That comes later. A more pressing issue is the 19 million tonnes of rock spoil that will emerge from the tunnel network as blasting really gets underway. Though some truck transport will be used, most of the route is environmentally protected.

"So most of the spoil will be removed by water transport," said Niland. Rock spoil inside the tunnel will be moved to crushers sited underground, to limit noise and dust, and then sized spoil will go by conveyor to one of three jetties which are being built for loading bulk transport ships. The client has purchased the sites for those and has also made arrangement with three buyers to sell the spoil. As a hard granite there is no difficulty in finding users for concrete making and other aggregate purposes. Some will go north and some south, said Niland.

"We have taken these measures as the client to ensure a level playing field for the bids," he added, "because the local contractors tend to have arrangements already in place for this kind of disposal."

Some of the earlier works for access tunnels are underway at present with smaller contracts in the US$50 million range, Czech contractor Subterra has one for example. But many of the main bids are still in progress for the major contracts, which are up to $300 million. There are six for the junctions and another half dozen for the main tunnelling works which get underway in earnest next year.

The client split the jobs into these packages to ensure the market could cope said Brantmark, "…though in the event it seems we could have gone bigger – some offers for discounts to take two packages have been received."

There could be some delays for the moment however because several of the big contracts are being contested in the courts at present over award procedures.

These major tunnelling works are expected to continue until 2022. After that comes the mechanical and electrical and ventilation works and installation of the control systems, signalling, lighting and signage.

Possibly by then the technology will have further advanced and it is difficult at this stage to be precise about the details. Current opening schedule is mid-2026.

A key element of the project has been the decision by the Swedish government's Roads Authority to make the project a full Building Information Modelling project (World Highways Software supplement 2012). It is the first major project done this way in the country and a step towards full BIM procedures for the future.

Implementation of the BIM system has been part of a design exercise carried out since 2011 by a consulting joint venture of Sweden's ÅF and international consultant URS, now part of the1397 Aecom group.

The team, together with the Trafikverkert, (Sweden's Road and Rail Authority), has developed a complex set of protocols and procedures for design development and communication, together with a methodology for publishing and passing on information.

A "common data environment" is part of this, where documents are tracked and versioned very carefully.6197 Bentley's ProjectWise server system has been used to implement that along lines used on the London Crossrail project.

At the heart of the new system is full use of 3D models for both design and tendering of the project, and then it is hoped, the development and passing on of models as construction proceeds.

There is still the use of drawings for some early parts, according to Trafikverkert, which added that the electronic model has a priority in the hierarchy of the contract process.

The client does not insist that contractors use the model for their own procedures if they do not wish. Contractors can extract drawings for site work for example. But the client wants the communications carried out using 3D information. It hopes the models will be passed on with added as built information, potentially all the way to the asset management stage of the project.

A key aspect is that any exchange must be software vendor neutral and for the moment that is handled by using the more common file formats like DNG and DWG as well as XML. These are integrated as a common federated model using the I-model system.

Although the system will put Sweden at the forefront in using electronic models it is still only a level two BIM says one of the Aecom engineers involved. But a full common 3D model is the target.

Another continuing aspect of the project as it enters the construction stage is the developing use of simpler apps and systems to extract and use information on site via "Cloud" applications like Navisworks 360. This is likely to evolve as the scheme gets into full swing.

After years of preparation and design, blasting and rock moving for Sweden's largest infrastructure project began south of the city this year. It sets in train a decade-long project that will create a new half-ring dual three-lane motorway for the city, 20km long. With most of it deep underground, it will also be one of Europe's largest ever road tunnels. The scheme is aimed at transforming a growing congestion problem for Sweden's capital which can be a highly frustrating city for residents trying to move around, and especially those in the south wanting to work in the north or, vice versa. "In medieval times the water was a means of movement but nowadays it is an obstacle," said Jesper Niland, technical manager for the project client, the Swedish Road Authority.

"At times it can seem like there are almost two cities and getting from one to the other is a major difficulty" added overall project director, Johan Brantmark. After just a day or two in the city the snarl-ups are obvious with traffic jams almost constant for extended rush hours. It can sometimes take hours to get home by car.

The impact of the congestion is mainly within Stockholm itself, affecting the 2.2 million or so people living in the Stockholm metropolitan area. There is passing traffic heading to the relatively unpopulated north but that is currently fairly limited and some 95% of the traffic is local. "It either starts or finishes in the city or both," said Brantmark.

The introduction of a congestion charge some years ago lowered traffic volumes, but not sufficiently to fully address the congestion problem. Rail links that could help are also overextended, although a new "City Banan" central train line will open next year. But though the new line doubles the current twin-track line capacity of the central station, it will only partially meet demand.

The problem arises from the geography of the city, which sits between the edge of the Baltic archipelago and several large inland lakes and further associated islands. It is a beautiful setting, and makes Stockholm one contender for the perhaps overworked "Venice of the North" designation, with all its waterways. But it also means the city is split in two by a large channel.

"And there are only three links across," said Brantmark. One of these is around the central island of the old city, where "the Sluice" separates the lake and the Baltic, and another on a bridge over the lake. "But the only high-capacity crossing is the E4 route on the west side."

Not only does this restrict traffic, it leaves the transport network vulnerable, he said. "If a bridge is damaged, and we have had some incidents of barge collisions or if repairs are needed, the impact is significant."

The proposed solution is a new motorway link which will essentially reroute the E4 motorway west of the capital, running south to north, and joining to a new northern link running eastwards across the city. Together with an eventual southern section this will make a half ring outer motorway. The eastern half is not needed as that would put it in the Baltic Sea.

The old E4 will remain but redesignated as a local road and with reduced traffic loads. "These are currently about 110,000 vehicles/day," said Brantmark. The new route is expected to see traffic volumes increase up to 140,000 vehicles/day, some 10 years after it opens in 2026.

But passing the road westwards has been fraught with problems, and some political objections, which for a while suspended the project while its go-ahead was debated. Most of these issues are environmental; contesting the overall existence of the road itself and its location.

For many "greens" the new road, which began significant design work in 2011, was seen as encouraging and perhaps stimulating traffic growth. That would be causing unacceptable emissions at a time of global warming; investment should instead go on new metros.

"A new government in 2014 therefore made a reassessment of the project but eventually decided it should go ahead," said Brantmark, "not least because the city is quite rapidly growing."

A second issue is the potential damage to some relatively pristine areas the route must cross, including several lake waterways and a large island, Lovön, which includes a royal palace and is mostly parkland over the rest of its area.

"The result is that, as the decades have gone by, an original proposed scheme mostly above ground has been more and more put underground," said Niland. The central part of the scheme will now be a single underground section 16.5km long with a further 1.8km tunnel section to the north after a junction with an existing motorway. There are short at-grade sections at the end too.

Not only is the scheme very long for an urban tunnel but it will also drop fairly deep, as much as 65m below sea level, to ensure that it can pass beneath the water channels and any cracks and fissures there might be in Sweden's very hard rock.

And it will be huge; a twin bore tunnel for a full motorway of three lanes in each direction and associated safety shoulders. The total width of the two rock bores is 16m. Along with the main tunnel there must also be a large number of approach and leaving ramps for various junctions, including one at each end linking into the existing E4; one at the north end between the two tunnels sections where the E18 route passes east to west; and two intermediate junctions, one on the island of Lovön and another in an urban area north of that. As these junctions will also be partly underground, an additional 14km of ramp tunnel is needed, as well as further work for seven access tunnels.

The junctions are significant projects in themselves, particularly the Häggvik junction in the north and the Kungens Kurva, where the road ties into the existing motorway at the southern end, each having multi-lane sections and major bridge and ramp structures above ground as well as below.

The challenges in carrying through these projects are not simply the design of the structures themselves and their construction but also the need to keep the existing traffic flowing freely, or at least as freely as it can be said to flow at present.

"Safety, and security are the top watchwords for the project," explained Brantmark, "and that includes avoiding any disruption of the circulation or making the network any more vulnerable. Keeping the vehicle users free from extra stress is important."

The junction contracts, currently being let after a long international tendering period, are therefore to be done on a design-build principle. The aim is to encourage innovation from the contractors, particularly with temporary works and traffic management.

"The tunnel works are done differently. As with all tunnels we follow the principle that the ground conditions can be variable and are therefore the responsibility of the client, more or less in line with the British code of practice which evolved after the Heathrow tunnel collapse."

Design will be done by the client, with the contractor responsible for implementation. Extensive geotechnical investigation and coring has been done to assess rock quality.

Sweden has long experience in hard rock tunnelling and this obviously informs the design of the project, which will be carried out by traditional drill and blast methods. The rock is primarily a granitic gneiss, commonplace throughout the ancient rocks of the Baltic Shield.

In Sweden the basic excavation technique always includes extensive pre-grouting of the rock on most projects, ensuring that cracks and fissures are sealed and the rock is "tight" to fairly severe limits of water leakage.

That is especially important on this route where there is a reasonable level of fracturing and cracks in the rock said Niland, not least from the lake bed sections above.

Though it takes longer to do things this way, "…it is usually quite successful and means the requirements for lining the rock tunnel against water ingress are reduced," said Brandt, who holds a doctorate in rock mechanics himself.

A major issue to come will be blasting vibrations particularly in the southern sector and further north where the tunnels pass underneath urban areas and buildings. Rock transmits vibrations rather too well. Some mitigation measures are already underway including the mass double glazing of a housing estate near to one of the sites for a junction.

Not all the tunnelling will be in hard rock however, and there are sections particularly, as ramps approach the surface, which most cope with clays and glacial tills laid down during the Ice Age.

The tunnel itself has some modern features, most notably an inner envelope set around half a metre in from the rock excavation walls. "This is to make an inner seal and also to set a good shape for the tunnel interior," explained Niland. It is made using a flexible membrane supported on rock bolts standing out from the bare rock walls and then coated with layers of shotcrete to form a rigid shell.

"The older method was a drainage mat and shotcrete on the rock but this offers better control of water leaks," said Niland.

He explained that the space outside the shell is inaccessible. But for later maintenance a newly developed semi-robotic scanner is being modified from one used at present for the London Underground, to pick up any changes in the rock profile over the years.

Sweden famously pays a lot of attention to road safety – the Volvo car is known for it, and the design of the tunnel will reflect that. The major feature is a cross-passage system linking the two sides allowing for evacuation in the event of a fire or crash and for the access of emergency services from vehicles in the opposite carriageway. The relatively small passages are sealed with pressure doors and contain communication links, firefighting equipment and water hydrant points.

"The principle is 'self-evacuation' through short but frequent tunnels," said Niland. The cross-passages will be made every 100m which is much above the 300m level common in many modern tunnel systems such as the Gotthard high speed, and even more above the European minimum of 500m.

The cross-passage system is part of a tunnel fire system that includes heat and smoke detectors and emergency radio communications network.

Ventilation is another important aspect of the tunnel safety both in emergencies and during normal operation. With an anticipated 140,000 vehicles/day, keeping the air clean and safe presents a significant challenge.

Surprisingly the design has gone for a longitudinal system using ceiling mounted jet-flow fans, where the fan output drags the rest of the tunnel air along. For very long tunnels over 4km it is more normal to provide a system using under road or ceiling ducts, drawing in or pushing air out through slots.

Such tranverse systems need more structure however and more complex air flow and control.

"We are able to use a longitudinal system because the tunnel has been broken into sections," said Niland. "Every 4km there is an air exchange station which draws fresh air from the surface through a vent and discharges stale air through another. We had a lot of discussion on this and design and modelling studies."

The 8m diameter intake and out-take vents are spaced 100m apart and will require some major raise boring work to reach the surface from the 65m depth of the tunnels. They are fitted with big tranverse fans, some 48 in all, complementing 250 jet fans in the tunnels. Additional smoke extraction-only vents to the surface will be provided near the tunnel entrances.

Taken together, the system and associated air quality, smoke and air temperature detectors, will allow a fairly high level of control over different sections of the tunnel and also a means to isolate smoke and heat from fires.

A water sprinkler system will also come into play in the event of fires, says Brandt.

Another safety aspect for the tunnel will be an architectural interior finish and variated lighting to change the appearance of the tunnel for drivers as they pass through. However, 16km is a long drive underground and ways to keep drivers alert are needed.

That comes later. A more pressing issue is the 19 million tonnes of rock spoil that will emerge from the tunnel network as blasting really gets underway. Though some truck transport will be used, most of the route is environmentally protected.

"So most of the spoil will be removed by water transport," said Niland. Rock spoil inside the tunnel will be moved to crushers sited underground, to limit noise and dust, and then sized spoil will go by conveyor to one of three jetties which are being built for loading bulk transport ships. The client has purchased the sites for those and has also made arrangement with three buyers to sell the spoil. As a hard granite there is no difficulty in finding users for concrete making and other aggregate purposes. Some will go north and some south, said Niland.

"We have taken these measures as the client to ensure a level playing field for the bids," he added, "because the local contractors tend to have arrangements already in place for this kind of disposal."

Some of the earlier works for access tunnels are underway at present with smaller contracts in the US$50 million range, Czech contractor Subterra has one for example. But many of the main bids are still in progress for the major contracts, which are up to $300 million. There are six for the junctions and another half dozen for the main tunnelling works which get underway in earnest next year.

The client split the jobs into these packages to ensure the market could cope said Brantmark, "…though in the event it seems we could have gone bigger – some offers for discounts to take two packages have been received."

There could be some delays for the moment however because several of the big contracts are being contested in the courts at present over award procedures.

These major tunnelling works are expected to continue until 2022. After that comes the mechanical and electrical and ventilation works and installation of the control systems, signalling, lighting and signage.

Possibly by then the technology will have further advanced and it is difficult at this stage to be precise about the details. Current opening schedule is mid-2026.

A key element of the project has been the decision by the Swedish government's Roads Authority to make the project a full Building Information Modelling project (World Highways Software supplement 2012). It is the first major project done this way in the country and a step towards full BIM procedures for the future.

Implementation of the BIM system has been part of a design exercise carried out since 2011 by a consulting joint venture of Sweden's ÅF and international consultant URS, now part of the

The team, together with the Trafikverkert, (Sweden's Road and Rail Authority), has developed a complex set of protocols and procedures for design development and communication, together with a methodology for publishing and passing on information.

A "common data environment" is part of this, where documents are tracked and versioned very carefully.

At the heart of the new system is full use of 3D models for both design and tendering of the project, and then it is hoped, the development and passing on of models as construction proceeds.

There is still the use of drawings for some early parts, according to Trafikverkert, which added that the electronic model has a priority in the hierarchy of the contract process.

The client does not insist that contractors use the model for their own procedures if they do not wish. Contractors can extract drawings for site work for example. But the client wants the communications carried out using 3D information. It hopes the models will be passed on with added as built information, potentially all the way to the asset management stage of the project.

A key aspect is that any exchange must be software vendor neutral and for the moment that is handled by using the more common file formats like DNG and DWG as well as XML. These are integrated as a common federated model using the I-model system.

Although the system will put Sweden at the forefront in using electronic models it is still only a level two BIM says one of the Aecom engineers involved. But a full common 3D model is the target.

Another continuing aspect of the project as it enters the construction stage is the developing use of simpler apps and systems to extract and use information on site via "Cloud" applications like Navisworks 360. This is likely to evolve as the scheme gets into full swing.