Among the forests and lakes of Finland, one of Europe's newest motorway links is being built as a Green highway linking Europe to Russia - Adrian Greeman reports

The road eastwards from Finland's capital Helsinki, along the north coast of the Gulf of Finland, has not carried heavy traffic volumes, at least until recent times. Highway seven as it is designated locally, or E18 in European nomenclature, is partly motorway but in some sections still dual carriageway or even just a single lane each way, finishing at the border with Russia. The Cold War did not encourage a high frequency of vehicles.But things have been changing since the end of the Soviet Union. Trade is increasing, and if an anticipated change in visa regulation takes place, relaxing currently still stringent requirements, tourism and other traffic could grow very substantially.

"We already have sometime significant traffic jams and tailbacks of many trucks if there is blockage or restriction at the border customs" said Jaakko Kouvalainen, managing director for Tieyhtiö Valtatie 7, a concession consortium currently financing and building an upgrade to the road. "The worst one stretched back for 60km and there has often been 30km of congestion."

There are also a number of fatalities on the road each year he said, perhaps three or four and many more non-fatal accidents. It needs upgrading.

On top of these factors, the road is also increasingly important both for Finland and for the European Union which designates it as the E18, part of a triangular network linking all the Scandinavian capitals, Oslo, Stockholm, Copenhagen and Helsinki. Western extensions reach as far as the Atlantic coast in Ireland, and down through Germany. Within Finland it connects the important port of Turku and most of the important airports and ports in most populated southern part of the country.

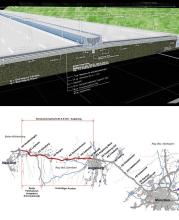

A section of road further eastwards near Hamina and to the near-border town of Valimaa, is already motorway but there is a 53km section which needs upgrading, closer to Helsinki. It starts just before the town of Loviisa, along to Kotka. Some 17km of this is dual carriageway which is to be widened and brought to motorway standard, and the rest will be new motorway.

It will follow the alignment of the existing road in the first part and then a new roughly parallel alignment further on through green field, or rather, green forest ground.

The road design and construction has to tread sensitively for both ecological and perhaps political reasons. It is being built under only the second private-public partnership arrangement that the country has used for highway work and the consortium running it is keen to make sure it goes well and without causing any upsets.

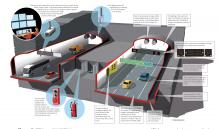

A key aspect of the road is to reduce congestion and noise for the various towns along the route but needs to do this without causing any new problems of its own. For this sensitive project therefore a number of environmental initiatives have been taken, both during construction and in the permanent design to make the road a green highway.

"It is a kind of experimental concept," said Kouvalainen. The consortium has worked with local businesses, municipalities and the regional government to develop the ideas.

There are a variety of measures to create this green status. Some are more obvious such as extensive sound barriers and noise reduction in the built-up and suburban housing areas along the road. "None of the affected houses will have a noise exposure greater than 55 decibels" said Kouvalainen.

There are both bicycle and pedestrian ways alongside the road, which have been welcomed by the local community populations and there is protection for the ground water in some sensitive sections. "We are lining the sub-base of the road with protective membranes in some 20 different locations," he said, explaining that in these areas there are sensitive aquifers used for community water extraction. Some 4km of highway in total will get the lining treatment to contain any diesel or other spills that might happen.

"During construction too there are special locations for the refuelling of drills, earthmovers and other equipment too," he added.

Perhaps more high tech and modern are measures to reduce road energy consumption, especially in lighting, which will be controlled by a smart computer system linked to light level detection.

In the far northern latitudes the quotidian reduction and increase in daylight hours is unusually pronounced as the seasons change, and precise tracking of the light levels to avoid switching lights on at the wrong moment, offers substantial savings, additionally if weather is taken in to account.

"We will also be using modern LED lights, though these will only be for the service areas," he added. Service stations will also have solar panels for electricity generation and will use heat pump systems for the heating and cooling requirements with a network of buried pipes to extract and return ground energy. It is another important measure in a country which sees winter temperatures of around -30°.

Along the highway a full VMS virtual messaging system is to be installed with telematic control also being extended back as far at the town of Porvoo nearer Helsinki, covering over 80km of road. It will provide speed limits, accident and emergency warnings, weather information and road closure announcements. Again in a region of heavy snow and ice this is even more important than usual.

Structures on the highway will also provide a green message. Architecturally this will be done with various green sensitive finishes for concrete pillars and structures, most prominent of which is an unusual timber overbridge. This large bridge with two 31m long spans either side of a central column will be a double bowstring arch superstructure in specially treated laminated wood. It is impregnated with safe anti-rot chemicals to give a long lifespan.

There are also a number of wildlife green bridges on the route, overpasses specifically tailored for use by the forest animals which include reindeer, moose, and many other species. The bridges will provide vegetated green corridors which the animals will accept as just part of the forest. Along with five locations for these, there are to be another four animal underpasses.

A total of 68 bridges are needed for local road crossings, waterways and as part of six new interchanges along the route. Most of the remaining structures are relatively small and of standard construction said Kouvalainen.

The only really significant structures lie at the centre of the project where it crosses a major river outlet. First there is a twin tube tunnel 400m long through a rock bluff overlooking the river and then the road will pass immediately onto two fairly significant bridges.

The first is a concrete span structure across the first part of the river and the second has an unusual central steel arch supporting the decks more or less as cantilevers either side. The total crossing is 272m long.

Construction of these is the major complication of the work which is being done at present by a consortium comprising two major Finnish firms, Yit Rakennus and

The majority of the work is straightforward said Kouvalainen, comprising cutting and embankment. The major complication is that like virtually all of Finland much of the alignment is across hard pinkish granite, part of the ancient rocks making up the billion year old Baltic Shield. The work requires considerable drill and blast and there are constraints on when and how often it can be done. "We have to keep traffic hold ups to just eight minutes in the sections where work is underway adjacent to the existing highway," said Kouvalainen.

Around 3.6 million tonnes of rock has to be shifted for cuttings. Most of this, around 2.7 million tonnes, is being reused in fill and embankment areas. Some of this is being crushed for road bed material but surprisingly not all of it requires crushing. "For the sub-base the broken rock spoil can be placed directly," said Kouvalainen. "Then any irregular or oversize pieces are broken down using a hydraulic hammer on an excavator. The largest stone is not allowed to be greater than half the thickness of the layer."

The contractor has been using the locally produced

Not all the ground is hard however and there has been a need for both soil stabilisation and even piled slab support in some soft ground areas. Altogether some 200,000m of bored piles have been needed. Soil mixing has also been used to consolidate around 350,000m3 of ground.

But this work has been conventional said Kouvalainen. The challenge in the work is keeping to a very tight schedule he says, with first sections due to open in 2013 despite starting only after the concession was signed at the very end of 2011. Getting traffic running is important for the operating consortium which is paid for the road over the next 12 years on an "availability" formula by Finland's Road Transport Authority.

The Markkinamäki tunnel and the big bridges across the Pyhtää branch of the Kymijoki River are the most complex parts of the physical construction.

As might be expected, the tunnel drives through the same pinkish granite and is being done by the drill and blast method which is almost universal in Scandinavia. A small surprise is the Swedish

The semi-automatic underground drill is used for both of the parallel tunnel drives from west to east which will each carry one of the twin-lane sides of the motorway, with room for an emergency lane. It switches over from one to the other as required said YIT tunnel supervisor Oleg Sanatsin.

The large 122m2 face of each tunnel, 9m high by 14m wide, is being drilled and blasted in sections, two for the northern side and three on the southern drive.

Sanatsin said, "For design reasons it is not allowed to do a full face blast and anyway it works better with the two sections, because the rock is blasted forwards from the first section."

Each drill round works 6m deep which is substantial. "We did start with 3m and worked up" said Sanatsin. The blast is done with an emulsion explosive, "…which is more powerful than the cartridges."

The second tunnel works with three sections to the blasting sequence he says. It is not quite as fast as the two section face but offers additional flexibility and allows the logistics of mucking out and drilling to be adjusted to keep the drill machine and

"We try to do two blasts a day," said Sanatsin, "with the drill and loading taking around five to six hours for a half face and perhaps three hours for the smaller area in the other tunnel. Mucking out and anchoring is around 10 hours.

Support in the sound rock is not excessive, comprising mostly rock anchoring in the crown and top sides of the tunnels, 4m long in the roof and 3m for the sides, followed by a thin 60mm thick shotcreting. The Atlas Copco machine does all this drilling too, "…and quite fast," he said.

The tunnel will be fitted out later with big heavy concrete side panels, for both vehicle impact protection and insulation, a major requirement in the very cold winter air of the north. For the same reason the tunnel entrance blast was done only on one side to restrict the passage of cold air and when the breakthrough point was reached in December the rock was left unblasted so that icy air will not come through.

"We will finish the breakthrough in March," said Kouvalainen.

Icy conditions have also had their effect on the bridge work during foundation installation last year, which was done partly from cofferdams in the river. The bridges cross the river just downstream from a medium sized hydroelectric plant and it can let out water suddenly when the generators start up.

"This was bringing ice blocks downstream towards our works," said Susanna Poutanen, a site engineer for the bridge with the joint venture contractor. "We had to build platforms around them to carry an excavator which pushed the ice blocks away."

Timber cofferdams were used on the longer concrete bridge which carried the road directly as it emerges from the tunnel. It has four spans, the first of 36m and the others each 45m and the piers for the first two are in the water which is about 5m deep. The others are on an island which separates two channels of the river.

The cofferdams were made onshore and pushed into the river bed before plugging the base with concrete. Foundations are 1.5m diameter bored piles through a 6m alluvial layer above the granite bedrock. Reinforcement within the piles is drilled and grouted 3m into the rock layer beneath. Piers above are concrete and about 5m high.

"We could do the foundations in the dry on the island for the other piers and an abutment structure which is shared by the second bridge," she explained.

"The supports for the ends of the arch bridge are also on land though there is an old stone river wall we had to deal with in the water."

This second bridge, which runs continuously with the first, is slightly shorter with two side spans of 22.5m long and a central arch supported span of 90m. Its steel arch is designed to echo an existing steel bowstring arch bridge on the old road which will remain in use.

But for what will be a signature structure the designers have chosen an unusual single plane bowstring running along the centre of the deck and supporting the deck either side. At the abutments the arch itself is supported by a short row of three piles at either end with an "outrigger" pile at either side which prevents twisting actions in the road deck.

Steel for the bridge is being fabricated by Finnish company

Work on this section of the road is due to conclude at the end of 2014, because it has the greatest technical challenges. A linking section of 11km of new motorway on the western side also finishes in in 2014. But the remaining sections of the project, which has been divided into six work packages, must complete this year.

It is a tight schedule said Kouvalainen and this has really been the greatest challenge of the project in the main, rather than complex technicalities. It has meant designers

The need for a timely opening is accentuated by the nature of the concession for the project. Unusually for a design, build, finance and operate scheme, the concession has a relatively short run, ending in 2026. There is some experience of PPP work in Finland said Kouvalainen but only on the Turku section of the E18. So caution prevails.

The Valtatie Group will be paid therefore on an daily availability basis for each of the six sections.

The overall contract totals €623 million covering construction into 2015 and maintenance until 2026. The largest part of the funding comes from major partners in the Valtatie group, Paris-based

KEY FACTS

Measures to reduce road energy consumption, especially in lighting, which will be controlled by a smart computer system linked to light level detection

There are both bicycle and pedestrian ways alongside the road, which have been welcomed by the local community populations

Along the highway a full VMS virtual messaging system is to be installed with telematic control covering over 80km of road

Service stations will have solar panels for electricity generation and will use heat pump systems for the heating and cooling requirements with a network of buried pipes to extract and return ground energy

Wildlife green bridges on the route will provide vegetated green corridors which the animals will accept as just part of the forest. Along with five locations for these, there are to be another four animal underpasses