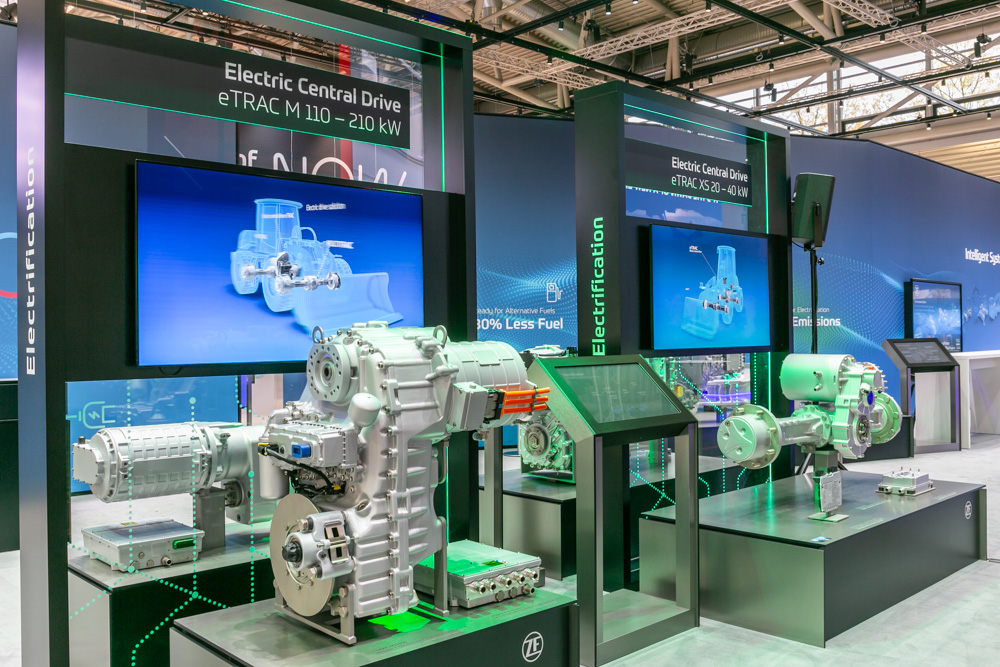

While the firm is already producing its eTRAC eCD20-40 electric drives for compact vehicles, and the first pilot projects are underway for the next larger eCD 50-90 series, the newly-developed eCD160 system will offer solutions for electric construction machinery weighing up to 20tonnes.

The components are matched to a system consisting of an electro-mechanical powershift transmission and one e-motor for traction and ePTO each. An electric drive control unit for overall system performance and power management completes the system. With a 650V operating voltage, the system can be scaled up to 120kW continuous power; the ePTO ranges from 30-70kW continuous power.

Based on the established ERGOPOWER powershift technology, the eTRAC system is not intended to replace the conventional driveline technology. Instead, its modular design that allows a large number of drive concepts to be covered and to react even more flexibly to customer requirements in the future.

The newly developed solution can be integrated into battery-electric vehicles as well as vehicles with fuel cells. At the same time, conventional drives with powershift and power split transmissions will remain, even for alternative fuels such as hydrogen, eFuels, or biodiesel.