The unit is a steel mini-silo with a capacity of 3m3 and is intended to speed up the cement loading process and ensure accuracy for the mix design. The machine includes a load-cell container that weighs the quantity of materials loaded, helping to ensure precise quantities are used in the mix. As a result, normal sized cement bags and large bags can be used. After loading, a feed screw carries the content into a

Its design is said to help boost productivity and lower operating costs, according to the firm. The Carmix Bagger can be carried by a forklift and its compact size helps to minimise shipping costs.

The use of large cement bags is said to reduce dust, while also cutting the costs for bag disposal. In addition, loading big bags helps to reduce material costs and raises productivity. The Carmix Bagger can contain up to three 1m3 bags/cycle.

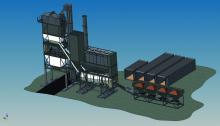

Versatile mixing from Metalgalante

Metalgalante says that its new Carmix Bagger offers high productivity, while reducing environmental impact at the worksite. The firm’s new Carmix Bagger is compatible with all of the Carmix machines and is said to help increase their productivity at the worksite.

The unit is a steel mini-silo with a capacity of 3m3 and is intended to speed up the cement loading process and ensure accuracy for the mix design. The machine includes a load-cell container that weighs the quantity of materials loaded, helping t

Metalgalante says that its new Carmix Bagger offers high productivity, while reducing environmental impact at the worksite. The firm’s new Carmix Bagger is compatible with all of the Carmix machines and is said to help increase their productivity at the worksite.