First, we report on a trial to combine in-situ cold recycling of structural pavement layers with graphene in a bid to improve flexibility and longevity. Then, there is a story about the use of porous asphalt in the UK; it has a bad reputation there, but in this case, it is being used at an airport to counter surface water and improve safety.

Rubber modification has been around for many years, but Tarmac has just got approval for a product which gives the green light for its wider use in the UK. And finally, the Australian Flexible Pavement Association is trying to phase out the use of hydrocarbons to cut back hot binders for spray seal, looking to countries including Germany, France and South Africa for inspiration.

Cold recycled road base gets boost with graphene

English road authority National Highways has trialled the use of graphene in the structural layers of a section of the A1 in North East England.

The base course and binder layers, to a depth of 160-180mm, were recycled in situ, with graphene added to improve the sub-base’s strength and durability.

Recycling in situ produces huge carbon savings: around 50% according to Stabilised Pavements which carried out the work, with 90.5% of material recycled. It also removed the need for 1,400 lorry movements. National Highways hopes that the graphene will increase the pavement life, leading to further carbon savings.

Once the failing surface layer had been planed off, Stabilised Pavements, working for framework contractor Galliford Try, used a Wirtgen W 380 CRi recycling machine to rip up the structural layers. The Wirtgen then pulverises the material and mixes in foamed bitumen, cement and pulverised fuel ash (PFA) before it is transferred to a paving machine to be laid and then compacted.

National Highways, formerly Highways England, began looking at how graphene could be used in its road networks around two years ago, having seen Iterchimica’s GiPave technology, according to Graeme Watt, National Highways’ asset needs manager for Yorkshire & North East.

“We started to look at how graphene’s properties could be exploited to improve the technologies we had to change the way materials perform and to improve asset life,” said Watt. National Highways looked at potential applications with the Graphene Engineering Innovation Centre (GEIC) at The University of Manchester, selecting the recycled sub-base as the first one to go ‘live’ onsite.

In Yorkshire and the North East of England, National Highways has been using cold recycling to reconstruct base and binder layers since 2016. “Cold recycling ticks multiple boxes, in terms of cost, carbon savings and customer experience: it reduces the length of schemes so that there is less disruption,” said Watt.

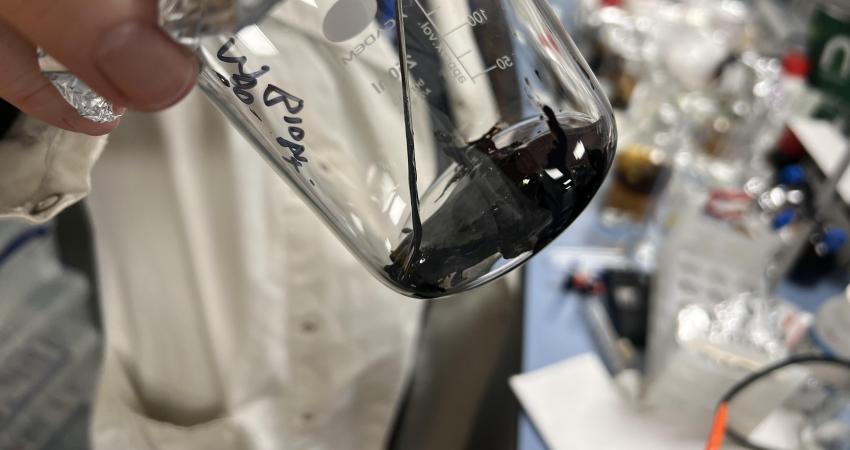

One of the challenges in deploying graphene in the sub-base was working out how to disperse the graphene, explains Stabilised Pavements’ head of commercial and business development Andy Jones, a task which specialist Cemblend helped with: “They had to work out whether they could effectively distribute such a small amount of graphene powder into around 28tonnes of (cement and PFA) powder,” said Jones.

Stabilised Pavements carried out the work on a two-lane, 5.2km stretch of the A1 between Newton-on-the-Moor and West Cawledge in September 2021. The crew achieved an average of 1,184tonnes/shift, working over 12 shifts.

“The second-generation Wirtgen machine allows us to control the gradation of the material which is key because it increases the durability of the product,” said Jones. “The machine travels at a constant speed but you can change the speed of the drum and retain material in the drum longer if you need to.”

Adding PFA to the mix will also increase the longevity of the road base, explained Jones. “The PFA reduces the void content. Particularly with foam, it’s important to have fines because the bitumen clings to the fine end of the material rather than to the aggregates.”

As for the effect of the graphene, laboratory trials carried out by Pavement Testing Services show that it increases the material’s strength without increasing the likelihood of it cracking, said Watt. Early tests at the onsite lab where the trial was carried out showed the graphene had an immediate effect.

“There was a very evident increase in the early strength which is likely to be due to the interaction between the graphene and the cement,” said Watt. “The next step will be that the graphene starts to interact with the bitumen.”

Now National Highways and GEIC will be looking at other applications for graphene such as in pavement preservation, coatings for crash barriers and road markings. One limiting factor to graphene’s wider use currently, however, is its cost. “It’s a frighteningly expensive addition,” said Jones.

Next gen porous asphalt for UK airport

A new hard-wearing porous asphalt has been laid on the runway of RAF Odiham in Hampshire, UK, for the Defence Infrastructure Organisation (DIO). FM Conway developed the mix for contractor Toppesfield which was working for UK infrastructure services supplier Amey.

Porous asphalt contains voids which allow water to drain through it. It is used extensively in countries including the Netherlands, Japan and some parts of the US. In the UK, it is not widely used on the road network, although its use is now increasing for commercial and residential applications where the designers have to incorporate sustainable urban drainage systems (SUDS) to deal with rainwater at source.

Although porous asphalt was used on airfields historically in the UK, SMA (stone mastic asphalt) has become the traditional choice, explained Mark Flint, FM Conway’s technical manager for aggregates and asphalt. But with climate change leading to more intense bouts of rainfall, porous asphalt is on the agenda.

“The DIO is revisiting porous asphalt to see how it performs compared to traditional surfaces,” said Flint.

With both aircraft and materials science having evolved significantly since its last porous asphalt specification was written, the DIO produced a tough, new specification. Rather than a soft grade bitumen called for in the old specification, the new one demanded polymer modified bitumen (PMB). “Aircraft have changed quite a lot in the past 30-40 years, and materials have moved on too,” said Flint.

The first step in the design of the porous asphalt was finding a suitable PMB and gaining approval of it from the DIO. FM Conway used its SurePol HD PMB, which it modified slightly to meet the performance requirements.

“That was quite a tough process,” said Flint. “They were very, very specific on what they wanted, with low temperature properties being paramount.” The behaviour of bitumen at low temperatures is a good predictor of its resilience to reflective cracking.

“A lot of airfields were built at speed, during the war, which means that they can have poor subgrade,” said Flint. “Climate change, with more water and warmer weather means that the subgrade suffers even more.”

Having pinned down the PMB’s performance. FM Conway then had to design a mix which would provide the right volume of pores to allow the required draining rates, without the structure being too loose to hold together. Ensuring the mix was easy to work with was another priority, said Flint.

“You can make something in the laboratory and prove it meets a specification, but you have to make sure that it's layable, that it can be installed and compacted,” he says. Once laid, the porous asphalt was tested almost immediately to ensure that it drained at the required rate.

FM Conway was able to supply all of the 8,500tonnes of porous asphalt required from its Theale plant. And it devoted the plant to making material for the airfield, producing 600 tonnes a day.

“The material is safety critical, you have to make sure it’s consistently compliant,” said Flint. “By dedicating a plant, we could calibrate it to run that material only.” It took around a day to calibrate the plant to produce the porous asphalt, and the same plant operator oversaw production on each day, Flint adds.

The next steps for the DIO will be to monitor how the runway at Odiham performs, with tests carried out on a regular basis. If it does behave as expected, there will be a case to use it on other airfields, depending on ground conditions.

Rubber modification gains accreditation

Tarmac’s ULTIPAVE R has been approved under the British Board of Agrement (BBA) Highway Authority Product Approval Scheme (HAPAS), the first rubber-modified bitumen to do so, according to Tarmac.

The approval removes the need for individual authorities to carry out their own assessments and means it can be laid on the national highways network without needing to apply for a departure from specification.

Following on from the BBA approval in April 2021, Bradford Council’s Highway Maintenance North team laid around 700 tonnes of ULTIPAVE R on a section of Otley Road in the village of Eldwick in West Yorkshire, UK. By combining the rubber modified asphalt with Tarmac’s ULTILOW warm mix technology, further carbon savings are made – on average 3.5kg CO2e per tonne, according to Tarmac.

Councillor Alex Ross-Shaw, portfolio holder for regeneration, planning and transport, Bradford Council, said: “Using this innovative new product from Tarmac is a positive step in terms of decarbonising our operations. We will continue to work with suppliers and contractors to ensure that using materials like this becomes standard practice.”

Tarmac now can supply two rubber modified asphalts: rubber modified SMA which has 0.67% rubber and ULTIPAVE R which has 1% rubber. In getting ULTIPAVE R to a BBA accreditation standard, which was a two-year process, there were several hurdles to clear, said Tarmac’s national technical director Brian Kent.

“"Historically, attempts to use rubber in surface course asphalts were less successful due to the rubber absorbing the bitumen and the material becoming too dry, leading to surface fretting,” explained Kent. “This was overcome through R&D development and working with our rubber supply partner to carefully assess which rubbers would work best in asphalt,and fine milling this rubber to a typical 0.5-1mm particle size, which minimises any subsequent absorption.”

It is also necessary to use a slightly softer bitumen, said Kent, so that the final mix binder complies with the final mix target.

The rubber, which is end-of-life (ELT) car tyres, is supplied by Murfitts Industries who process it at their Suffolk plant. The material is produced using a dry mix process where the rubber is added directly to the mixer. “Modifications were required at operational plant level in terms of delivery and software upgrades to ensure rubber was added at the correct dosage,” commented Kent.

Both Tarmac’s ULTILOW R and Rubber Modified SMA have been used on several roads around the UK to date. The most heavily used section paved with ULTILOW R is a section of the slow lane on the M1 near junction 23 at East Midlands Airport.

Australia to phase out hydrocarbon cutters

The Australia Flexible Pavement Association (AfPA) is running a campaign to reduce the use of hydrocarbon cutters in spray sealing operations. Standard practice in Australia is to use kerosene to cut back hot binders for spray seals, whereas many developed countries have switched to alternative technologies.

The reason why AfPA wants to see this change is that using kerosene comes with a raft of problems: it has a low flash point; it contributes to air pollution; and it produces greenhouse gases. “AfPA has created a road map to incrementally introduce or develop alternative technologies and products to bring Australia in line with procedures adopted in other developed countries,” AfPA executive director technology & leadership Anna D’Angelo told a seminar on the subject in October 2021.

Cutters are used to reduce the viscosity of the binder, which is often necessary if the binder has been modified with polymer or crumb rubber. Using a kerosene-type cutter also means that pavements can be sprayed at lower temperatures (below 25ºC in Australia), for instance at night or in shaded areas.

Alternatives to hydrocarbon cutters include synchronised sprayers that allow instantaneous wetting of the aggregate with the hot binder; using bio cutters or vegetable derived oils; emulsions; and foam bitumen. Warren Carter, technical manager at Downer Group and a member of AfPA’s scientific committee told the seminar that many European countries now used polymer modified emulsions.

Next steps will be to encourage AfPA members to trial alternative technologies and then to work with local authorities to change specifications and consider awarding green credits.

New Zealand has already started its move away from cutters. The New Zealand Territorial Authority Board has approved a proposal where contractors can choose to spray with either cutback or emulsions, where the NZTA will pay a premium for using emulsion. South Africa banned the use of cutting back hot binders in 2000.