Two important routes in Germany, the A9 and A6 autobahn highways, have benefited from the use of the latest Wirtgen slipforming machines. The A9 is a particularly important route in Germany as this 529km link connects capital Berlin with the southern city of Munich, running through Brandenburg, Saxony-Anhalt, Saxony, Thuringia and Bavaria.

The SP 81i has been used to carry out barrier work on the A6 autobahn

Two important routes in Germany, the A9 and A6 autobahn highways, have benefited from the use of the latest Wirtgen slipforming machines. The A9 is a particularly important route in Germany as this 529km link connects capital Berlin with the southern city of Munich, running through Brandenburg, Saxony-Anhalt, Saxony, Thuringia and Bavaria.

The widening of a 19km section of the route between Triptis and Schleiz, just north of the town of Hof, was based on the public-private partnership model, a concept new to Germany. The contract demanded service requirements so that problems with quality or availability would result in the government reducing payments to the operator.3281 Eurovia headed the project team and was keen to demonstrate quality due to ITS 20 year concession package.

In order to maximise load-bearing capacity and service life, as well as provide good surface evenness and skid resistance, Eurovia opted to use concrete surfacing. A washed concrete design was selected, which helps reduce traffic noise emissions. Concrete surfacing offers high resistance to deformation, preventing the formation of ruts and offering long intervals between maintenance periods. The increasing volume of heavy goods traffic made this a crucial factor.

The work was needed on six lanes over the 19km, around 550km2 of paving and requiring some 165,000m³ of concrete. The construction team opted to use2395 Wirtgen SP 1500 and SP 1500 L slipform pavers to slipform two layers of concrete pavement in just one pass, achieving around 400-500m/day.

The first slipform paver was responsible for the subgrade. The 230mm lower-layer of concrete was paved by the SP 1500 L and compacted by an internal vibrator, with the SP 1500 L embedding dowels and tie bars in it. This design provided a base for the 70mm top-layer of concrete, with wet-on-wet paving used to provide a better bond between the concrete layers.

Concrete for the top-layer was provided from the bottom-layer concrete paver from a receiving hopper with a charging conveyor. It was then placed in front of the second slipform paver, which distributed and compacted the material across the paving width with its spreading plough.

The finishing beam and super smoother produced the necessary surface finish, while the pavement was sprayed with a TCM 1800 curing unit across its width after paving, preventing rapid evaporation and crack formation.

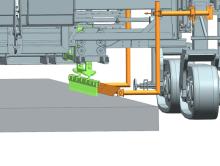

Meanwhile, Wirtgen's new SP 81i paver has been used for road surface renewal and the installation of a concrete safety barrier on the A6 autobahn between Schwetzingen and Mannheim. Eurovia has also carried out this work, employing the new Wirtgen SP 81i slipform paver as a trial of the newly launched machine on the A6. Around 3.6km of the route is being upgraded and the work is due for completion at the end of 2013.

The old surface was in poor condition and there was also a need to install new safety barriers along the section of road. Wirtgen's new SP 81i slipform paver, one of the new models unveiled at bauma 2013 in Munich, was used to form the concrete safety barrier.

Martin Datzert, sales and applications specialist for slipform pavers at Wirtgen explained, "We use pilot job sites like this one in order to receive direct feedback from our customers on our new machines. This gives us the opportunity of identifying any potential for optimisation."

Before delivery, the machine was modified to match the job, with final modification and the assembly of the mould mount and pushrod on site. At the same time, Eurovia Beton personnel were trained to operate the SP 81i. Eurovia Beton’s team was impressed by the fast unloading of the ready-mixed concrete trucks using the conveyor, which also proved easy to clean. Site manager for Eurovia Beton, Rüdiger Arndt, commented on the operator's platform of the SP 81i, "The operator has a good overview of the entire paving process."

Arndt also highlighted the low noise of engine, the benefit of the ECO mode for fuel consumption and the precision of metering of the proportional control for steering.

The widening of a 19km section of the route between Triptis and Schleiz, just north of the town of Hof, was based on the public-private partnership model, a concept new to Germany. The contract demanded service requirements so that problems with quality or availability would result in the government reducing payments to the operator.

In order to maximise load-bearing capacity and service life, as well as provide good surface evenness and skid resistance, Eurovia opted to use concrete surfacing. A washed concrete design was selected, which helps reduce traffic noise emissions. Concrete surfacing offers high resistance to deformation, preventing the formation of ruts and offering long intervals between maintenance periods. The increasing volume of heavy goods traffic made this a crucial factor.

The work was needed on six lanes over the 19km, around 550km2 of paving and requiring some 165,000m³ of concrete. The construction team opted to use

The first slipform paver was responsible for the subgrade. The 230mm lower-layer of concrete was paved by the SP 1500 L and compacted by an internal vibrator, with the SP 1500 L embedding dowels and tie bars in it. This design provided a base for the 70mm top-layer of concrete, with wet-on-wet paving used to provide a better bond between the concrete layers.

Concrete for the top-layer was provided from the bottom-layer concrete paver from a receiving hopper with a charging conveyor. It was then placed in front of the second slipform paver, which distributed and compacted the material across the paving width with its spreading plough.

The finishing beam and super smoother produced the necessary surface finish, while the pavement was sprayed with a TCM 1800 curing unit across its width after paving, preventing rapid evaporation and crack formation.

Meanwhile, Wirtgen's new SP 81i paver has been used for road surface renewal and the installation of a concrete safety barrier on the A6 autobahn between Schwetzingen and Mannheim. Eurovia has also carried out this work, employing the new Wirtgen SP 81i slipform paver as a trial of the newly launched machine on the A6. Around 3.6km of the route is being upgraded and the work is due for completion at the end of 2013.

The old surface was in poor condition and there was also a need to install new safety barriers along the section of road. Wirtgen's new SP 81i slipform paver, one of the new models unveiled at bauma 2013 in Munich, was used to form the concrete safety barrier.

Martin Datzert, sales and applications specialist for slipform pavers at Wirtgen explained, "We use pilot job sites like this one in order to receive direct feedback from our customers on our new machines. This gives us the opportunity of identifying any potential for optimisation."

Before delivery, the machine was modified to match the job, with final modification and the assembly of the mould mount and pushrod on site. At the same time, Eurovia Beton personnel were trained to operate the SP 81i. Eurovia Beton’s team was impressed by the fast unloading of the ready-mixed concrete trucks using the conveyor, which also proved easy to clean. Site manager for Eurovia Beton, Rüdiger Arndt, commented on the operator's platform of the SP 81i, "The operator has a good overview of the entire paving process."

Arndt also highlighted the low noise of engine, the benefit of the ECO mode for fuel consumption and the precision of metering of the proportional control for steering.