Advanced weigh-in-motion (WIM) systems can offer a quick payback time

A weigh station in Pakistan showing Central Weighing's SUPAWEIGH System

Highway maintenance costs are only one reason to increase overweight vehicle enforcement. Increased safety and reduced highway repair downtime can also be achieved using a WIM system that can pay for itself in overall reduced highway maintenance costs, says 1315 Intercomp, which has been designing and manufacturing electronic weighing systems for over 33 years.

The cost to the public of an overweight vehicle, as compared to a legal vehicle, is significant.

A study conducted in 2006 by the state of Arizona, USA, concluded that uncompensated damages to roadways are between US$12-53 million/ year. The benefit/cost ratio for increased enforcement expenditures is between 100-500%, according to the study, Estimating the Cost of Overweight Vehicle Travel on Arizona Highways (Sandy H. Straus and John Semmens, Arizona Department of Transportation, January 2006).

Intercomp's WIM system consists of two main components: the selection stage and the precision measurement stage, says the company.

In the selection stage the vehicle's weight and height are measured to determine if the vehicle is legal. (Loop sensors in the pavement keep the readings of closely spaced vehicles separated). If either test is failed, traffic lights will direct the vehicle to the precision measurement stage.

The precision measurement stage consists of a very precise scale that meets or exceeds all government standards. The precise scale determines the weight of each axle and sensors determine if dual or single wheels are on the axle being weighed.

An additional height detector determines if the vehicle meets regulations, while an electronic licence plate reader automatically reads and stores the licence number of a vehicle that does not meet regulations. (An image of the licence is also stored.) "Customisable software allows the user to interpret and display the data in a way that best suits their application," says Intercomp, which is ISO 9001:2008 registered and which has facilities in the US and UK to serve its worldwide customer base.

"If the vehicle is legal, it will be directed back onto the highway. If in violation of height or weight regulations, traffic lights will direct the vehicle to a holding area.

"A traffic control arm, which is controlled by the software, is also used to prevent vehicles that exceed weight or height regulations from returning to the highway." Additional weighing sensors are located in the highway to alert the authorities of vehicles attempting to bypass the weigh station.

Intercomp's WIM system uses electronic strain gauge load cells, and these are used for many reasons, says Intercomp.

"They are the most accurate, are effectively temperature compensated, are low profile and are the most reliable." The company's products are developed and tested on a complete private onsite WIM test station, which is complete in every detail and includes stop lights, dual wheel sensor, licence plate reader and even a traffic control arm to test WIM systems in a real-world application.

"Intercomp's electronic weighing products are used extensively in the transportation industry including a full line of measuring devices for law enforcement.

"Based on the data from the Arizona study, the Intercomp WIM system will pay for itself in reduced highway maintenance costs," added the company.

180 Central Weighing also points to the damage caused by some heavily overloaded trucks, which it claims are doing over 300 times the damage to the road of a correctly loaded truck.

"It is vital for any government to have access to this kind of data in order to tailor enforcement to reduce the problem, thus conserving valuable financial resources for other essential programs such as health and education," says the company, which has been among those at the forefront of slow-speed WIM technology for nearly 30 years and has some 3,500 installations worldwide.

It has now developed two new products for launch at the346 Traffex 2011 exhibition [Birmingham, UK from 29-31 March].

Working in both the fleet management and law enforcement markets, the company says it has developed the hardware and software to meet the requirements of both demanding markets, and with tremendous growth in the international road tolling markets it has developed the new products for Traffex.

The SUPAWEIGH 5000 is an advanced, medium speed WIM system "giving the high accuracy of a slow-speed weigher at speeds of 10km/hour, which makes it ideal for the tolling application weighing trucks of any size in less than ten seconds."

The company has also developed and integrated Automatic Number Plate Recognition (ANPR) and Automatic Vehicle Classification (AVC) systems to offer a total solution for toll operators and enforcement agencies alike.

"The software is plug and play design, enabling new features to be added at the touch of a button," says Central Weighing.

"Vehicles arriving at the new high-technology tolls are classified in accordance with local regulations and weighed axle by axle in a matter of seconds. By the time they stop at the toll booth the data is already processed and a comprehensive report on the overload status of all axles, axle groups and both gross and train weight is available to the toll operator." The system also calculates any applicable fines and for offending vehicles the vehicle image and/or the licence plate number are recorded on the weighing document.

Importantly for road concessions, the system also calculates the equivalent standard axles for each vehicle weighed, which clearly shows the level of road wear for all trucks, enabling concessionaires to estimate the life expectancy of the road and budget accordingly.

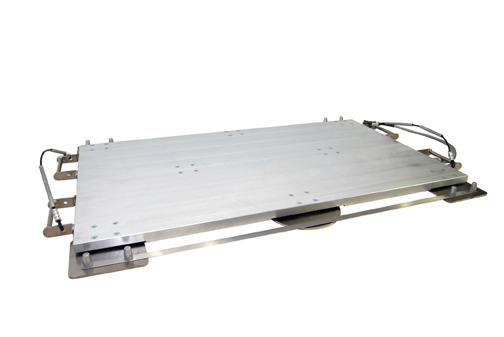

In many countries portable systems are preferred to fixed locations such as toll locations and this is an area in which Central Weighing has invested heavily in new product development, resulting in the launch of the new CHEKLODE Freeweigh, which is designed for use in all climatic and operational conditions.

"Heavy duty, aluminium weighpads that can withstand well over 15,000kg per wheel have been linked to an advanced weighing console using both Bluetooth and Ethernet technology, enabling totally cable-free operation. The weighpads can be located at around 10m from the weighing terminal, which can be situated in an adjacent vehicle to take advantage of the vehicle power supply to offer continuous, uninterrupted operation. Where no vehicle is available, the internal rechargeable batteries give over eight hours of operation from a single charge," says Central Weighing.

The new design features are, however, concentrated in the console and pc-based software.

Vehicle weighing data can be processed in the terminal and a multi-copy print out is instantly available for the driver but simultaneously the data is transferred either to a USB memory stick for subsequent download and analysis in an office based PC or directly in to the new Freeweigh Live System, which enables operation in any language directly through the pc.

"This overcomes any language problems and the operator can switch from English to the local language, producing operational instructions, weight tickets and reports in any language.

"Like the fixed products, CHEKLODE Freeweigh can be preprogrammed to automatically calculate overloads and fines as applicable in any country, removing any doubt about human errors when entering data or calculating penalties. Also like the fixed systems, the new CHEKLODE Freeweigh can be connected to a camera and large driver weight display for the ultimate in portable weight enforcement." According to Central Weighing, over 15 countries have already placed substantial orders following worldwide demonstration tours throughout the Middle East and Asia Pacific regions undertaken by the company's managing director Richard Stokes.

248 IRD) was awarded a new contract in Mongolia by MCS Electronics, which will act as the contractor for the project, scheduled to be commissioned in early 2011.

The project involves the supply and installation of IRD's WIM and toll collection systems along the Tavan Tolgoi-Gashuun Sukhait toll road, a crucial route being used to enhance mining development and expansion in the Gobi region bordering China. The toll road is built to transport coal to China from the Ukhaa Khudag coal deposit, a high quality coal deposit in Mongolia.

The contract involves the supply of a toll system at four plazas as well as four pre-selection slow-speed WIM sorting systems to keep overloaded trucks off the road.

All overweight trucks will be prevented from using the toll road.

Terry Bergan, president and chief executive officer of IRD, said: "We are extremely pleased to be extending our presence in Asia with this important new contract. Our installed solution will ensure proper asset management of the toll road and provide suitable monitoring and screening to assist with proper operations and management of this important transportation link between Mongolia and China."

The cost to the public of an overweight vehicle, as compared to a legal vehicle, is significant.

A study conducted in 2006 by the state of Arizona, USA, concluded that uncompensated damages to roadways are between US$12-53 million/ year. The benefit/cost ratio for increased enforcement expenditures is between 100-500%, according to the study, Estimating the Cost of Overweight Vehicle Travel on Arizona Highways (Sandy H. Straus and John Semmens, Arizona Department of Transportation, January 2006).

Intercomp's WIM system consists of two main components: the selection stage and the precision measurement stage, says the company.

In the selection stage the vehicle's weight and height are measured to determine if the vehicle is legal. (Loop sensors in the pavement keep the readings of closely spaced vehicles separated). If either test is failed, traffic lights will direct the vehicle to the precision measurement stage.

The precision measurement stage consists of a very precise scale that meets or exceeds all government standards. The precise scale determines the weight of each axle and sensors determine if dual or single wheels are on the axle being weighed.

An additional height detector determines if the vehicle meets regulations, while an electronic licence plate reader automatically reads and stores the licence number of a vehicle that does not meet regulations. (An image of the licence is also stored.) "Customisable software allows the user to interpret and display the data in a way that best suits their application," says Intercomp, which is ISO 9001:2008 registered and which has facilities in the US and UK to serve its worldwide customer base.

"If the vehicle is legal, it will be directed back onto the highway. If in violation of height or weight regulations, traffic lights will direct the vehicle to a holding area.

"A traffic control arm, which is controlled by the software, is also used to prevent vehicles that exceed weight or height regulations from returning to the highway." Additional weighing sensors are located in the highway to alert the authorities of vehicles attempting to bypass the weigh station.

Intercomp's WIM system uses electronic strain gauge load cells, and these are used for many reasons, says Intercomp.

"They are the most accurate, are effectively temperature compensated, are low profile and are the most reliable." The company's products are developed and tested on a complete private onsite WIM test station, which is complete in every detail and includes stop lights, dual wheel sensor, licence plate reader and even a traffic control arm to test WIM systems in a real-world application.

"Intercomp's electronic weighing products are used extensively in the transportation industry including a full line of measuring devices for law enforcement.

"Based on the data from the Arizona study, the Intercomp WIM system will pay for itself in reduced highway maintenance costs," added the company.

Ready for launch

UK-based"It is vital for any government to have access to this kind of data in order to tailor enforcement to reduce the problem, thus conserving valuable financial resources for other essential programs such as health and education," says the company, which has been among those at the forefront of slow-speed WIM technology for nearly 30 years and has some 3,500 installations worldwide.

It has now developed two new products for launch at the

Working in both the fleet management and law enforcement markets, the company says it has developed the hardware and software to meet the requirements of both demanding markets, and with tremendous growth in the international road tolling markets it has developed the new products for Traffex.

The SUPAWEIGH 5000 is an advanced, medium speed WIM system "giving the high accuracy of a slow-speed weigher at speeds of 10km/hour, which makes it ideal for the tolling application weighing trucks of any size in less than ten seconds."

The company has also developed and integrated Automatic Number Plate Recognition (ANPR) and Automatic Vehicle Classification (AVC) systems to offer a total solution for toll operators and enforcement agencies alike.

"The software is plug and play design, enabling new features to be added at the touch of a button," says Central Weighing.

"Vehicles arriving at the new high-technology tolls are classified in accordance with local regulations and weighed axle by axle in a matter of seconds. By the time they stop at the toll booth the data is already processed and a comprehensive report on the overload status of all axles, axle groups and both gross and train weight is available to the toll operator." The system also calculates any applicable fines and for offending vehicles the vehicle image and/or the licence plate number are recorded on the weighing document.

Importantly for road concessions, the system also calculates the equivalent standard axles for each vehicle weighed, which clearly shows the level of road wear for all trucks, enabling concessionaires to estimate the life expectancy of the road and budget accordingly.

In many countries portable systems are preferred to fixed locations such as toll locations and this is an area in which Central Weighing has invested heavily in new product development, resulting in the launch of the new CHEKLODE Freeweigh, which is designed for use in all climatic and operational conditions.

"Heavy duty, aluminium weighpads that can withstand well over 15,000kg per wheel have been linked to an advanced weighing console using both Bluetooth and Ethernet technology, enabling totally cable-free operation. The weighpads can be located at around 10m from the weighing terminal, which can be situated in an adjacent vehicle to take advantage of the vehicle power supply to offer continuous, uninterrupted operation. Where no vehicle is available, the internal rechargeable batteries give over eight hours of operation from a single charge," says Central Weighing.

The new design features are, however, concentrated in the console and pc-based software.

Vehicle weighing data can be processed in the terminal and a multi-copy print out is instantly available for the driver but simultaneously the data is transferred either to a USB memory stick for subsequent download and analysis in an office based PC or directly in to the new Freeweigh Live System, which enables operation in any language directly through the pc.

"This overcomes any language problems and the operator can switch from English to the local language, producing operational instructions, weight tickets and reports in any language.

"Like the fixed products, CHEKLODE Freeweigh can be preprogrammed to automatically calculate overloads and fines as applicable in any country, removing any doubt about human errors when entering data or calculating penalties. Also like the fixed systems, the new CHEKLODE Freeweigh can be connected to a camera and large driver weight display for the ultimate in portable weight enforcement." According to Central Weighing, over 15 countries have already placed substantial orders following worldwide demonstration tours throughout the Middle East and Asia Pacific regions undertaken by the company's managing director Richard Stokes.

Mongolian contract

Late last year, International Road Dynamics (The project involves the supply and installation of IRD's WIM and toll collection systems along the Tavan Tolgoi-Gashuun Sukhait toll road, a crucial route being used to enhance mining development and expansion in the Gobi region bordering China. The toll road is built to transport coal to China from the Ukhaa Khudag coal deposit, a high quality coal deposit in Mongolia.

The contract involves the supply of a toll system at four plazas as well as four pre-selection slow-speed WIM sorting systems to keep overloaded trucks off the road.

All overweight trucks will be prevented from using the toll road.

Terry Bergan, president and chief executive officer of IRD, said: "We are extremely pleased to be extending our presence in Asia with this important new contract. Our installed solution will ensure proper asset management of the toll road and provide suitable monitoring and screening to assist with proper operations and management of this important transportation link between Mongolia and China."