Overweight vehicles cause enormous damage to road structures but they can be caught, even at high speed. Weigh-in-motion or WIM devices are designed to capture and record axle weights and gross vehicle weights as vehicles drive over a measurement site.

A truck is weighed on a bridge in Colombia, South America, using Central Weighing's new Supaweigh equipment

Overweight vehicles cause enormous damage to road structures but they can be caught, even at high speed

Weigh-in-motion or WIM devices are designed to capture and record axle weights and gross vehicle weights as vehicles drive over a measurement site. Unlike older static weigh stations, current WIM systems are capable of measuring at normal traffic speeds and do not require the vehicle to stop or drive at low speed, making them much more efficient.Each year, damage to highways from overloaded trucks costs billions worldwide, and reducing this will save in repair costs.

According to

"While the main factor affecting road repair and maintenance requirements is the number of trucks, trucks with axle loads higher than the legal limit cause a disproportionately high percentage of the damage to the infrastructure. Furthermore, overloading, whether of one or more axles or the whole vehicle, is also likely to have an adverse impact on traffic safety," says the company.

"When it comes to monitoring road traffic loads, attention is now increasingly focused not only on gross vehicle weight but also on axle and wheel load. The authorities have an appropriate interest in detecting vehicles with excessive axle loads.

"WIM systems have provided an effective means of data collection for pavement research and facility design, traffic monitoring and weight enforcement. In order to monitor the whole of the traffic the WIM devices are fixed installed into the pavement and connected with the data acquisition and collection instruments. The data can be sent online or in packages to the departments requiring such data." Kistler's Lineas WIM sensors are used worldwide for data collection (analysis of traffic statistics); enforcement of weight limits (pre-selection); toll roads (weight dependent toll); research (analysis of pavement loading) and traffic management.

Its newly-designed double-length Lineas is a state-of-the-art sensor for WIM applications, and is fully compatible with the previous version (Type 9195E with lengths of 0.75m or 1m). However, one sensor row covering a traffic lane consists of only two sensors instead of four.

"Thanks to the new lengths (1.5m, 1.75m or 2m), sensor installation and cable routing can be done faster and more easily: as a result system and installation costs are lower." The Lineas is based on quartz, which is said to be the leading technology for dynamic measurements in a rough environment.

The WIM sensor, which when installed requires no maintenance, can be used for accurate weight measurements at low and high speed and in regions with extremely cold or warm climate. Indeed, its operating temperature range is -50°C to +80°C, and temperature influence is said to be negligible.

"Bikes can be weighed as accurately as heavy vehicles, and it measures accurately at any speed up to highway speed." According to Kistler, installation of Lineas sensors is fast and easy, requiring a few steps. The intrusion into the pavement involves a slot 55mm deep and 72mm wide, and the lane is usually closed no longer than 6-8 hours.

Portable scales

Meanwhile, Central Weighing, a leading UK vehicle axle weighing specialist with 4,000 installations in over 35 countries, has introduced a number of new products.Richard Stokes, managing director, says that the company provides systems for both law enforcement and fleet management applications, and that exports play a vital part in the

"In recent years the company has secured many valuable contracts in the new area of road tolling and has developed a range of products specifically aimed at this high tech market sector," says Stokes.

"The introduction of the new Supaweigh 5000c has allowed weighing at much faster speeds than previously possible, making it an ideal solution for toll applications where high vehicle throughput is vital. The first 100 systems were installed in India and now a worldwide demand for this product is emerging." The Supaweigh software package has multi-lane capabilites and provides instant identification of overloaded trucks. Fines can be computed in accordance with national regulations either at the toll booth or sent via ethernet to the PC-based control system, which can be located some distance away from the toll in a dedicated enforcement area.

Central Weighing now provides in-ground automatic vehicle classification, which provides clear unmanned identification of a specific vehicle class. This data enables the weighing system to compare the weights found with those applicable for each weight class as defined in any country.

Vehicles found to be overloaded can trigger an ANPR (automatic number plate recognition) camera which records the vehicle identification onto the weighing ticket with a clear image of the offending truck and its number plate.

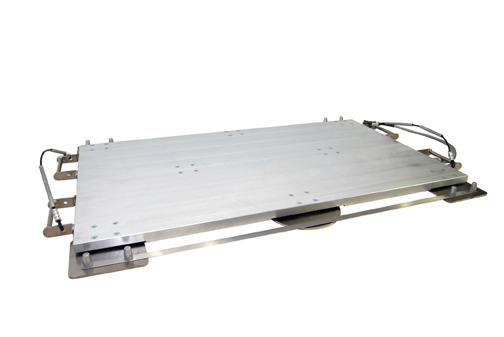

For vehicles that detour to avoid fixed weighing locations the company offers its Cheklode portable scales, claimed to be the most advanced portable scales on the market. The new Cheklode Freeweigh is cable-free and can weigh any size of truck in motion in a matter of seconds.

An integral memory stick facility allows the capture and storage of unlimited weighing data and the ability to transfer this data to a remote pc for archive and historic analysis where needed.

"Cheklode Freeweigh is available in standard and new maxi sizes, providing a durable and versatile weighing facility in even the harshest of operating conditions."

High-speed WIM

"Building on our success over many years we have been busy developing the next generation WIM classifier system incorporating the knowledge and experience gained from a number of successful projects culminating in the VOSA VIPER WIM/ANPR pre-selection enforcement systems," says Applied Traffic.

Three years ago it set up a dedicated design team to carry out research and development in partnership with Reading University, UK, with a remit of developing "the next generation" of traffic monitoring instrumentation systems.

The VIPERWIM classifier features up to eight-lane operation, real-time viewing of live traffic, waveform viewing, system diagnostics and configuration via the integrated touch-screen panel or via a locally connected laptop computer.

Joint agreement

An innovative technology package, that will boost road maintenance efficiency, has been developed under a joint agreement between Canadian companies International Road Dynamics (Providing an accurate assessment of current conditions and wear, and predicting future maintenance needs, the package uses sensors to provide accurate data in real-time on pavement temperature, climactic conditions, vehicle numbers and demographic information on vehicle types including size and weight.

A combination of WIM, traffic volume monitoring sensors, substructure strain sensors and temperature and rainfall monitors can be used to recover data continuously from each stretch of highway.

Mobile ground penetrating radar equipment or other mobile pavement assessment tools such as laser scanners fitted to vehicles travelling at highway speeds can analyse the road structure over a wide array of a network. This data can be combined with GPS location to provide an accurate picture of road conditions.

The system helps highway managers and concessionaires improve infrastructure and traffic management to maximise highway utility considering ever-changing environmental, substructure and traffic loading conditions.