Speed and precision have been the hallmarks of a number of major road tunnelling projects across the globe over the last 12 months, as the latest sector equipment from leading manufacturers has found itself in high demand. Guy Woodford reports

Herrenknecht tunnel boring machines (TBM) have been busy tunnelling under major Chinese rivers, demonstrating phenomenal speed, top safety levels and extreme precision while playing a key role in the construction of road tunnels in the Yangtze River Delta.

The Yang

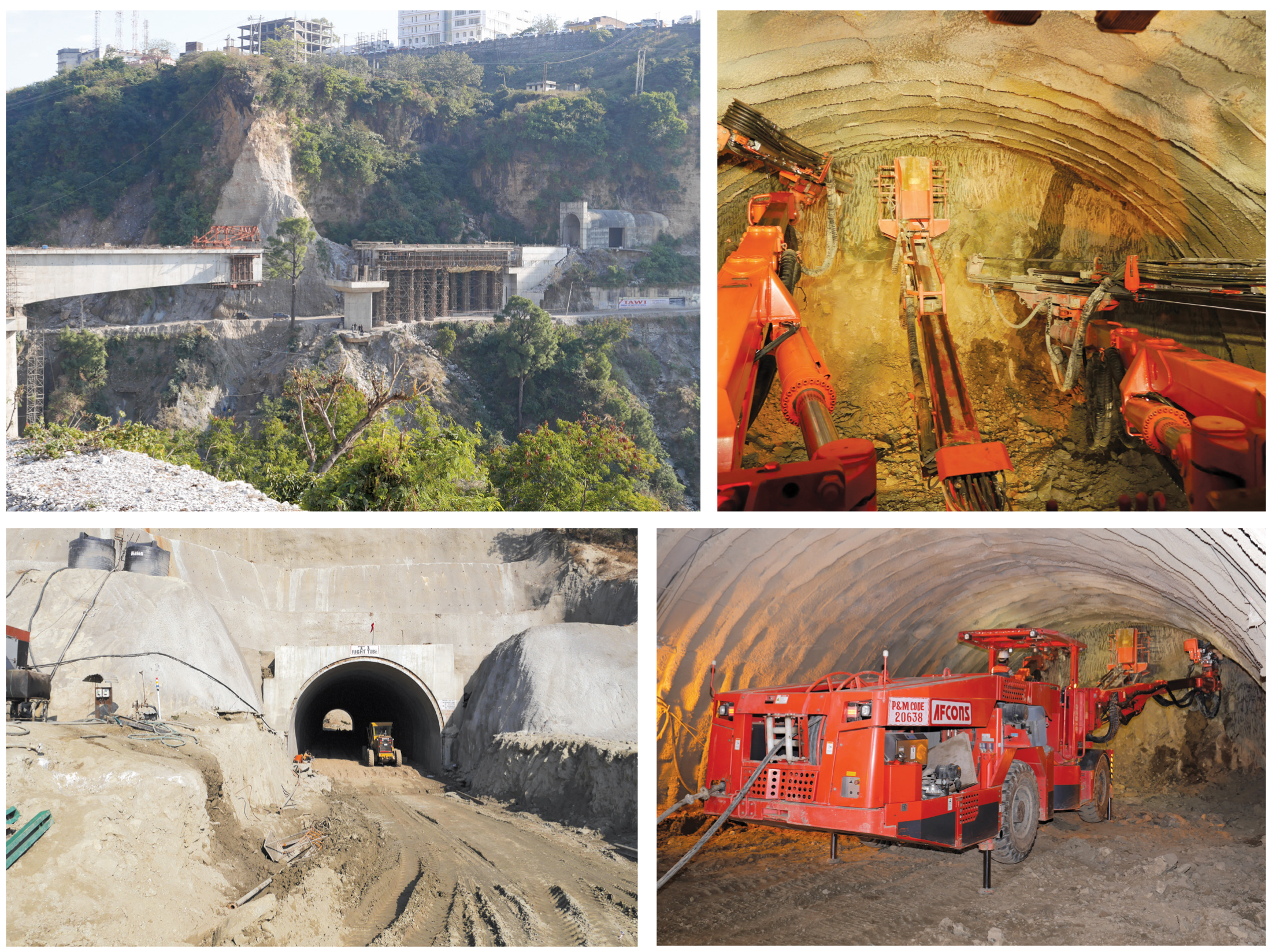

Afcons has been using two new Sandvik DT820 tunnelling drill jumbos to help produce four 1.5km twin tube tunnels as part of the $350mn redevelopment of the NH-1 in northern India

Speed and precision have been the hallmarks of a number of major road tunnelling projects across the globe over the last 12 months, as the latest sector equipment from leading manufacturers has found itself in high demand. Guy Woodford reports

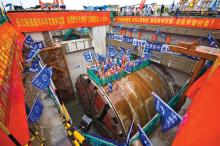

2592 Herrenknecht tunnel boring machines (TBM) have been busy tunnelling under major Chinese rivers, demonstrating phenomenal speed, top safety levels and extreme precision while playing a key role in the construction of road tunnels in the Yangtze River Delta.

The Yangtze River Delta in East China has developed rapidly to become one of the largest urban areas in the world. As a result, expansion of its infrastructure is progressing quickly too. On difficult crossings under rivers, Herrenknecht’s Mixshield TBM’s have been deployed on the Hangzhou Qiantang River Tunnel, the West Changjiang Road River Tunnel and the Shanghai Hong Mei Road Tunnel.

The annual, up to 9m high tidal wave of the Qiantang River at its mouth on the East China Sea is a tourist attraction. But a road bridge for the much-needed link between the northern and southern highways threatened to disrupt the view of the national attraction. The planners in Hangzhou therefore opted for mechanised tunnelling to create the Hangzhour Qiantang River Tunnel, choosing Herrenknecht’s S-593 Mixshield TBM - one of the world's two largest Mixshield models – for the project.

Tunnelling precision was required during drilling, because dam installations on the banks of the Qiantang protect the city of Hangzhou from flooding by the spring tide from the ocean. The dams were not allowed to be damaged under any circumstances, making the proven safety of the Mixshield technology an attractive option.

After the start of tunnelling, the S-593 TBM crossed under the Qiantang twice over a length of 3.25km and at a depth of up to 27.6m. After achieving a breakthrough, the Mixshield S-593 with a diameter of 15.43m is said to have completed its work with optimum values - with a maximum of 2.36cms, all subsidence measurements on the ground surface remained well within the limits defined by the authorities. The site crews of5250 Shanghai Tunnel Engineering Co (STEC) are said to have achieved rates of up to 464m per month.

Extreme precision was a priority during the advance of the Mixshield S-569 in Shanghai for the construction of two three-lane road tunnels for the West Changjiang Road River Tunnel project. With a diameter of 15.43m, the S-569 TBM drilled its way forward with only one metre leeway between the foundations of urban highway and railway line before it dived under the Huangpu River. The drilling specialists of STEC used a system for precise real-time monitoring of the shield position to handle the 40m-long passage.

With the same precision and safety, passing beneath 30 buildings was mastered as well as the advance in the immediate vicinity of 20 underground supply lines. With the breakthrough on June 19, 2013 the second of the two largest Mixshield machines in the world successfully completed its work in Shanghai.

Also in Shanghai, a few kilometres upstream from the West Changjiang Road River Tunnel, the Herrenknecht Mixshield S-666 is in operation on the Shanghai Hong Mei Road Tunnel. With a diameter of 14.9m, it is creating the longest and deepest lying road tunnel under the Huangpu River. Over a distance of 3.4km the TBM is achieving advances of up to 132m per week at depths of up to 59m below the water surface. After the first breakthrough on July 8, 2013 the STEC site crew checked all machine components and replaced necessary wear parts. Since December 28, 2013 the tunnel builders have been advancing the second tube in the opposite direction.

Two new325 Sandvik DT820 tunnelling drill jumbos have been assisting with the $350 million redevelopment of India’s National Highway 1 (NH-1) between Jammu and Udhampur - one of the country’s most significant current road projects.

Commissioned by the National Highway Authority of India, the northern India-based project is run along BOT (Build, Operate and Transfer) lines. In the process, the road will be extended from two to four lanes. After completion, the travelling time will be reduced from ten to around six hours. However, due to some extreme inclines, mass goods will continue to be transported north with the new rail link that is also under construction.

In the course of redeveloping the highway, around 150 bridges and numerous tunnels are to be built in the extremely inaccessible terrain of the Himalayas, and they will have to be adapted to the natural course of the mountains, valleys and ground conditions. The climatic conditions are extreme, varying from very high temperature in the summer to chillingly low in the winter, with snowfalls and monsoon rains. In addition, the construction sites are partly highly remote and the route leads through a wildlife sanctuary area at Nandini. As a result, drill and blast was precluded from the very outset and conventional driving was plumped for.

Over the new, planned four-lane 65km length of the NH1 Highway between Jammu and Udhampur, Afcons is engaged in producing four 1.5km twin tube tunnels. The project that began in 2011 is due to be completed this year, apart from a narrow road between Jammu and Srinagar. It is quite an achievement that Afcons is three months ahead of what is already an ambitious schedule. Biplob Chakraborty, general manager construction plant and equipment at Afcons, says, “We needed a special machine for excavation and drilling. We had to find a company which is very well known and established in the market. In tunnelling machinery, Sandvik is a preferred choice as their machines can work uninterrupted and supply hassle-free productivity.”

But for the experienced Afcons management, there is more than quality and a good reputation involved, “It is not only the machine that is important. After-sales, good service and maintenance are also a very big point for us when we decide for a supplier,"says Mihir Mishra, general manager (C.P.E.) at Afcons HQ in Mumbai.

The geology associated with the NH-1 project is typical for the Himalayas. Poor quality, broken rock with dolomitic limestone and firestone lentils with high silicate content is common. Rock class III to V, with strength of 60 to 100MPa and volume weight of 2.7t/m³, is prevalent. The RMR (rock mass rating) index amounts from 40 to 60. The tricky ground conditions in particular make it necessary to have a reliable partner for securing the rock. “The rock can collapse at any moment so that we must support the face quickly. We have a very reliable partner here with Sandvik,” Mishra continues. The use of highly flexible Sandvik DT820 tunnelling jumbos was considered a major advantage for the overall project. For example, if the face is very small, the two booms can be operated within the available limited space, just as is the case with a large face area.

The design of the four twin tube tunnels is said to be straightforward. The tunnels have a gap of 25m-30m between them. In case of emergency, every tunnel can be used for evacuation. They are produced by conventional mechanical cutting methods (NATM). The portals at the accesses to each tunnel are supported by steel arches over a 10m length. The tunnels are lined by placing a layer of wet shotcrete with steel fibre meshing.

Due to the requirements set by the sensitive environment (Nandini Sanctuary) and the local inhabitants, it is mandatory to use conventional mechanical cutting methods (non-blasting operation) in tunnel excavation.

At the face of the tunnel, the jumbo is used for drilling profile holes. The profile holes act as guiding lines for the mechanical cutting excavation; the 3m deep drill holes are created in order to be able to excavate the correct cross-section (tunnel profile). The actual excavation is done by different methods of mechanical cutting: roadheaders, drum cutter and vibro-ripper attachments. The muck is loaded by excavator on large dumpers and then transported out of the tunnel.

Sandvik jumbos are extensively used for rock stabilisation and roof bolting. For rock bolting, 54mm-64mm hole diameters with a depth of 4-10m are used. In case of very poor rock (Class IV and V), the Sandvik jumbos are also used for pipe roofing – or umbrella drilling – applications. A pipe roofing kit was retrofitted to both jumbos for this purpose, and now steel pipes with 114mm diameter and depths of 12-15m are inserted with the jumbos.

Along with DT820s, Afcons is also using Sandvik rock tools for profile drilling, roof bolting and pipe roofing applications. Sandvik drill jumbo and rock tools are the ultimate match for any challenging drilling conditions.

The Sandvik DT820 is a hydroelectric underground drill rig equipped with two booms and a utility boom as well as different optional instrumentation levels. Its coverage area ranges from 12-110m², the hole diameter from 43-63mm and the length from 3,440-6,180mm. The Afcons jumbos are equipped with a TFX-10/14ft. telescopic feed and a pipe roofing kit. With this equipment, it is possible to drill a tunnel of 8.42m in height and 14.21m in width.

Work on the NH-1 tunnels is said to be progressing well with an average advance rate of 14.5m per day. The excavation is likely to be finished in June 2014.

In Europe, one of the most important road construction projects in Austria - the 22km S10 Highway through the Mühlviertel district – includes the creation of a number of tunnels using203 Doka formwork solutions.

4178 Asfinag, Autobahnen- und Schnellstraßen-Finanzierungs-Aktiengesellschaft, (an Austrian highway and carriageway financing corporation), invested around US$995.4 million (€718 million) in order to realise this gigantic infrastructure project.

As part of European route E55, the S10 Highway serves as an important strategic connection to the South Bohemian and Baltic Sea regions. Furthermore, the eagerly awaited commuter route is intended to significantly reduce traffic as well as increase road safety. As a result of local topography, construction of the S10 requires enormous earth movements and numerous building operations in order to overcome natural obstacles. In order to level the path for the S10 and its future users, the construction firms involved are building four tunnels, four sub-surface tunnels, five interchanges, seven overpasses, 17 bridges, six passages, one gallery and several retaining walls.

This type of mega-project is not common and demands near-perfect planning, coordination and implementation know-how from all participants. "In Doka, we have a reliable partner whose product quality is as convincing as its implementation and quick response times," says3976 PORR Bau site manager Franz Hrebik. One of the essential project challenges was producing formwork for a wall area exceeding 13,000m². In contrast to conventional standard procedures, Doka was able to save around 4,900 form ties thanks to its innovative formwork solution. As a result, working time and costs were significantly reduced and construction progress accelerated.

For the S10 highway’s Neumarkt Tunnel, each of the tunnel tubes is 1,970m long with an inside radius of 5.05m. For its tunnel formwork, the construction company uses Doka’s modular heavy-duty supporting system SL-1 in combination with the large-area formwork Top 50 and high-capacity hydraulics. Given the limited space available, this formwork solution provides the necessary flexibility due to the variable arrangement of system beams, waling units and struts.

Meanwhile, both tubes of the Pernau Sub-surface Tunnel are 270m long and feature a round cross-section. The new tunnel system DokaCC is deployed successfully in this project. In close cooperation between construction firms, planners and Doka, the tunnel formwork system was conceived so that it can be adapted to the complex, slightly rotating geometry of the structure in the course of the procedure.

The Ganglsiedlung Sub-surface Tunnel consists of two tubes, each 275m long. Their clear widths measure 9.8m with a clear height of 5.68m. This structure was also formed with the DokaCC tunnel system. Here, the flexibility of the tunnel system for cut-and-cover construction is clearly evident. The same forming wagon is used at another time for a second project location with a different cross-section. Adaptation to both structure geometries requires little additional material cost.

Doka's large-area formwork Top 50 has been used for forming the 13,344m² wall area of the Walchshof Sub-surface Tunnel. Using the Top 50’s quick-release nut, designed to smoothly release anchoring tensile forces of up to 220kN, results in savings of 4,900 form ties compared to the standard solution, significantly lowering cost and saving working time.

All S10 Highway works are due for completion in 2015.

Earlier this year, UVEK (the Swiss Federal Department of Environment, Transport, Energy and Communications) opened up the new two-lane A4 mini motorway interconnecting the greater region of Zürich with Schaffhausen, a city in north-east Switzerland. The mini motorway is playing an important role for the economic development of the Schaffhausen region, but has led to a dramatic shift of traffic into the inner city of Neuhausen.

As part of a traffic relief strategy, the construction of the new Galgenbuck tunnel has been scheduled to half the 25,000 plus vehicles that commute daily through Neuhausen.

From Schaffhausen south, the A4 will create a 1,138m long tunnel with a slope of 4.5%, through the Galgenbuck Klettgau to the main road into the 13th link with the A4 intersections.

The workers of the Joint Venture WIGA (3332 Walo Bertschinger AG (FF) with Implenia Schweiz AG) will have to drillblast their way through rather difficult terrain. The local karst formation is hard to predict and the excavation will need to find its way through different layers of solid and unconsolidated rock, clay and rubble.

Atlas Copco2646 MEYCO is making a key contribution to these works with the provision of a MEYCO Potenza shotcrete mobile. The MEYCO Potenza accompanied the start of the tunnel work when it fortified the slope to create the portal in mid-2012.

Now that the main excavation is moving on by means of top heading and bench method, the MEYCO Potenza is constantly applying sprayed concrete to safeguard the excavation.

Atlas Copco (Schweiz) in Studen is also providing the Galgenbuck construction site with service and spares to guarantee a smooth operation. The major tunnel works will run until 2019.

A VARIOKIT tunnel formwork solution from298 PERI is said to have accelerated construction progress for the 228m long Marchlehner gallery in Austria, situated 1,800m above sea level. The competent planning took into account all possible project requirements which ensured on-schedule completion before the onset of winter.

The village of Vent is located 1,900m high in the Ötztal Alps and – in contrast to the nearby winter-oriented ski resort of Sölden in the Ötztal Valley – has established itself as a popular all-year-round attraction for mountain climbers. The only road connection passes through the narrow Venter Valley with a number of gallery constructions guaranteeing safe access for visitors by providing protection against avalanches and falling rocks.

With the completion of the Marchlehner gallery at the end of 2013, the L240 road between Sölden and Vent can now be safely negotiated along the complete route. The 228m long tunnel construction closes the gap between two existing galleries. The cross-section of the gallery measures 9.20m x 4.90m in the road axis direction and features an inclined supporting column structure with discontinuous wall buttresses on the valley side.

For realising the gallery slab, the experienced Teerag-Asdag AG (Tyrol subsidiary) construction crew used a tunnel formwork carriage on the basis of the VARIOKIT engineering construction kit. In addition to the short construction schedule, the challenge was to take into account the relatively high volume of traffic of around 1,000 vehicles per day during the actual execution of construction work. In order to ensure that traffic – including trucks and buses – could pass through the formwork carriage during all stages of construction without restrictions, PERI engineers and the site management designed a customised project solution. This was also said to be very cost-effective due to the use of mainly standardised, and therefore rentable, VARIOKIT system components.

The formwork concept consisted of a 13.5m long slab formwork carriage with a 3m wide and 4.5m high access portal, as well as four craneable formwork units for the valley-side 1.5m cantilevered tunnel slab. In order to ensure that the total of 19 tunnel sections were completed on time and before winter set in, two standard 12m cycles were formed, reinforced and concreted per week on average. Hydraulic operations as well as the very light 35tonne construction weight resulted in a fast moving procedure on each occasion by means of heavy-duty rollers – in spite of the extremely steep incline of around 8% in this section of the route. In addition, the VARIOKIT formwork carriage could be easily adapted to the changing radii of the S-shaped gallery with the help of the integrated transverse launching units.

PERI delivered a wide range of prefabricated formwork and construction units to the job site which meant valuable time advantages could be achieved right at the beginning of this project. The planning and execution of the stopend formwork, including accommodation of the water stop, were said to be integral parts of PERI´s comprehensive overall solution. This meant numerous time-consuming working steps on the construction site could also be saved.

The Yangtze River Delta in East China has developed rapidly to become one of the largest urban areas in the world. As a result, expansion of its infrastructure is progressing quickly too. On difficult crossings under rivers, Herrenknecht’s Mixshield TBM’s have been deployed on the Hangzhou Qiantang River Tunnel, the West Changjiang Road River Tunnel and the Shanghai Hong Mei Road Tunnel.

The annual, up to 9m high tidal wave of the Qiantang River at its mouth on the East China Sea is a tourist attraction. But a road bridge for the much-needed link between the northern and southern highways threatened to disrupt the view of the national attraction. The planners in Hangzhou therefore opted for mechanised tunnelling to create the Hangzhour Qiantang River Tunnel, choosing Herrenknecht’s S-593 Mixshield TBM - one of the world's two largest Mixshield models – for the project.

Tunnelling precision was required during drilling, because dam installations on the banks of the Qiantang protect the city of Hangzhou from flooding by the spring tide from the ocean. The dams were not allowed to be damaged under any circumstances, making the proven safety of the Mixshield technology an attractive option.

After the start of tunnelling, the S-593 TBM crossed under the Qiantang twice over a length of 3.25km and at a depth of up to 27.6m. After achieving a breakthrough, the Mixshield S-593 with a diameter of 15.43m is said to have completed its work with optimum values - with a maximum of 2.36cms, all subsidence measurements on the ground surface remained well within the limits defined by the authorities. The site crews of

Extreme precision was a priority during the advance of the Mixshield S-569 in Shanghai for the construction of two three-lane road tunnels for the West Changjiang Road River Tunnel project. With a diameter of 15.43m, the S-569 TBM drilled its way forward with only one metre leeway between the foundations of urban highway and railway line before it dived under the Huangpu River. The drilling specialists of STEC used a system for precise real-time monitoring of the shield position to handle the 40m-long passage.

With the same precision and safety, passing beneath 30 buildings was mastered as well as the advance in the immediate vicinity of 20 underground supply lines. With the breakthrough on June 19, 2013 the second of the two largest Mixshield machines in the world successfully completed its work in Shanghai.

Also in Shanghai, a few kilometres upstream from the West Changjiang Road River Tunnel, the Herrenknecht Mixshield S-666 is in operation on the Shanghai Hong Mei Road Tunnel. With a diameter of 14.9m, it is creating the longest and deepest lying road tunnel under the Huangpu River. Over a distance of 3.4km the TBM is achieving advances of up to 132m per week at depths of up to 59m below the water surface. After the first breakthrough on July 8, 2013 the STEC site crew checked all machine components and replaced necessary wear parts. Since December 28, 2013 the tunnel builders have been advancing the second tube in the opposite direction.

Two new

Commissioned by the National Highway Authority of India, the northern India-based project is run along BOT (Build, Operate and Transfer) lines. In the process, the road will be extended from two to four lanes. After completion, the travelling time will be reduced from ten to around six hours. However, due to some extreme inclines, mass goods will continue to be transported north with the new rail link that is also under construction.

In the course of redeveloping the highway, around 150 bridges and numerous tunnels are to be built in the extremely inaccessible terrain of the Himalayas, and they will have to be adapted to the natural course of the mountains, valleys and ground conditions. The climatic conditions are extreme, varying from very high temperature in the summer to chillingly low in the winter, with snowfalls and monsoon rains. In addition, the construction sites are partly highly remote and the route leads through a wildlife sanctuary area at Nandini. As a result, drill and blast was precluded from the very outset and conventional driving was plumped for.

Over the new, planned four-lane 65km length of the NH1 Highway between Jammu and Udhampur, Afcons is engaged in producing four 1.5km twin tube tunnels. The project that began in 2011 is due to be completed this year, apart from a narrow road between Jammu and Srinagar. It is quite an achievement that Afcons is three months ahead of what is already an ambitious schedule. Biplob Chakraborty, general manager construction plant and equipment at Afcons, says, “We needed a special machine for excavation and drilling. We had to find a company which is very well known and established in the market. In tunnelling machinery, Sandvik is a preferred choice as their machines can work uninterrupted and supply hassle-free productivity.”

But for the experienced Afcons management, there is more than quality and a good reputation involved, “It is not only the machine that is important. After-sales, good service and maintenance are also a very big point for us when we decide for a supplier,"says Mihir Mishra, general manager (C.P.E.) at Afcons HQ in Mumbai.

The geology associated with the NH-1 project is typical for the Himalayas. Poor quality, broken rock with dolomitic limestone and firestone lentils with high silicate content is common. Rock class III to V, with strength of 60 to 100MPa and volume weight of 2.7t/m³, is prevalent. The RMR (rock mass rating) index amounts from 40 to 60. The tricky ground conditions in particular make it necessary to have a reliable partner for securing the rock. “The rock can collapse at any moment so that we must support the face quickly. We have a very reliable partner here with Sandvik,” Mishra continues. The use of highly flexible Sandvik DT820 tunnelling jumbos was considered a major advantage for the overall project. For example, if the face is very small, the two booms can be operated within the available limited space, just as is the case with a large face area.

The design of the four twin tube tunnels is said to be straightforward. The tunnels have a gap of 25m-30m between them. In case of emergency, every tunnel can be used for evacuation. They are produced by conventional mechanical cutting methods (NATM). The portals at the accesses to each tunnel are supported by steel arches over a 10m length. The tunnels are lined by placing a layer of wet shotcrete with steel fibre meshing.

Due to the requirements set by the sensitive environment (Nandini Sanctuary) and the local inhabitants, it is mandatory to use conventional mechanical cutting methods (non-blasting operation) in tunnel excavation.

At the face of the tunnel, the jumbo is used for drilling profile holes. The profile holes act as guiding lines for the mechanical cutting excavation; the 3m deep drill holes are created in order to be able to excavate the correct cross-section (tunnel profile). The actual excavation is done by different methods of mechanical cutting: roadheaders, drum cutter and vibro-ripper attachments. The muck is loaded by excavator on large dumpers and then transported out of the tunnel.

Sandvik jumbos are extensively used for rock stabilisation and roof bolting. For rock bolting, 54mm-64mm hole diameters with a depth of 4-10m are used. In case of very poor rock (Class IV and V), the Sandvik jumbos are also used for pipe roofing – or umbrella drilling – applications. A pipe roofing kit was retrofitted to both jumbos for this purpose, and now steel pipes with 114mm diameter and depths of 12-15m are inserted with the jumbos.

Along with DT820s, Afcons is also using Sandvik rock tools for profile drilling, roof bolting and pipe roofing applications. Sandvik drill jumbo and rock tools are the ultimate match for any challenging drilling conditions.

The Sandvik DT820 is a hydroelectric underground drill rig equipped with two booms and a utility boom as well as different optional instrumentation levels. Its coverage area ranges from 12-110m², the hole diameter from 43-63mm and the length from 3,440-6,180mm. The Afcons jumbos are equipped with a TFX-10/14ft. telescopic feed and a pipe roofing kit. With this equipment, it is possible to drill a tunnel of 8.42m in height and 14.21m in width.

Work on the NH-1 tunnels is said to be progressing well with an average advance rate of 14.5m per day. The excavation is likely to be finished in June 2014.

In Europe, one of the most important road construction projects in Austria - the 22km S10 Highway through the Mühlviertel district – includes the creation of a number of tunnels using

As part of European route E55, the S10 Highway serves as an important strategic connection to the South Bohemian and Baltic Sea regions. Furthermore, the eagerly awaited commuter route is intended to significantly reduce traffic as well as increase road safety. As a result of local topography, construction of the S10 requires enormous earth movements and numerous building operations in order to overcome natural obstacles. In order to level the path for the S10 and its future users, the construction firms involved are building four tunnels, four sub-surface tunnels, five interchanges, seven overpasses, 17 bridges, six passages, one gallery and several retaining walls.

This type of mega-project is not common and demands near-perfect planning, coordination and implementation know-how from all participants. "In Doka, we have a reliable partner whose product quality is as convincing as its implementation and quick response times," says

For the S10 highway’s Neumarkt Tunnel, each of the tunnel tubes is 1,970m long with an inside radius of 5.05m. For its tunnel formwork, the construction company uses Doka’s modular heavy-duty supporting system SL-1 in combination with the large-area formwork Top 50 and high-capacity hydraulics. Given the limited space available, this formwork solution provides the necessary flexibility due to the variable arrangement of system beams, waling units and struts.

Meanwhile, both tubes of the Pernau Sub-surface Tunnel are 270m long and feature a round cross-section. The new tunnel system DokaCC is deployed successfully in this project. In close cooperation between construction firms, planners and Doka, the tunnel formwork system was conceived so that it can be adapted to the complex, slightly rotating geometry of the structure in the course of the procedure.

The Ganglsiedlung Sub-surface Tunnel consists of two tubes, each 275m long. Their clear widths measure 9.8m with a clear height of 5.68m. This structure was also formed with the DokaCC tunnel system. Here, the flexibility of the tunnel system for cut-and-cover construction is clearly evident. The same forming wagon is used at another time for a second project location with a different cross-section. Adaptation to both structure geometries requires little additional material cost.

Doka's large-area formwork Top 50 has been used for forming the 13,344m² wall area of the Walchshof Sub-surface Tunnel. Using the Top 50’s quick-release nut, designed to smoothly release anchoring tensile forces of up to 220kN, results in savings of 4,900 form ties compared to the standard solution, significantly lowering cost and saving working time.

All S10 Highway works are due for completion in 2015.

Earlier this year, UVEK (the Swiss Federal Department of Environment, Transport, Energy and Communications) opened up the new two-lane A4 mini motorway interconnecting the greater region of Zürich with Schaffhausen, a city in north-east Switzerland. The mini motorway is playing an important role for the economic development of the Schaffhausen region, but has led to a dramatic shift of traffic into the inner city of Neuhausen.

As part of a traffic relief strategy, the construction of the new Galgenbuck tunnel has been scheduled to half the 25,000 plus vehicles that commute daily through Neuhausen.

From Schaffhausen south, the A4 will create a 1,138m long tunnel with a slope of 4.5%, through the Galgenbuck Klettgau to the main road into the 13th link with the A4 intersections.

The workers of the Joint Venture WIGA (

Atlas Copco

Now that the main excavation is moving on by means of top heading and bench method, the MEYCO Potenza is constantly applying sprayed concrete to safeguard the excavation.

Atlas Copco (Schweiz) in Studen is also providing the Galgenbuck construction site with service and spares to guarantee a smooth operation. The major tunnel works will run until 2019.

A VARIOKIT tunnel formwork solution from

The village of Vent is located 1,900m high in the Ötztal Alps and – in contrast to the nearby winter-oriented ski resort of Sölden in the Ötztal Valley – has established itself as a popular all-year-round attraction for mountain climbers. The only road connection passes through the narrow Venter Valley with a number of gallery constructions guaranteeing safe access for visitors by providing protection against avalanches and falling rocks.

With the completion of the Marchlehner gallery at the end of 2013, the L240 road between Sölden and Vent can now be safely negotiated along the complete route. The 228m long tunnel construction closes the gap between two existing galleries. The cross-section of the gallery measures 9.20m x 4.90m in the road axis direction and features an inclined supporting column structure with discontinuous wall buttresses on the valley side.

For realising the gallery slab, the experienced Teerag-Asdag AG (Tyrol subsidiary) construction crew used a tunnel formwork carriage on the basis of the VARIOKIT engineering construction kit. In addition to the short construction schedule, the challenge was to take into account the relatively high volume of traffic of around 1,000 vehicles per day during the actual execution of construction work. In order to ensure that traffic – including trucks and buses – could pass through the formwork carriage during all stages of construction without restrictions, PERI engineers and the site management designed a customised project solution. This was also said to be very cost-effective due to the use of mainly standardised, and therefore rentable, VARIOKIT system components.

The formwork concept consisted of a 13.5m long slab formwork carriage with a 3m wide and 4.5m high access portal, as well as four craneable formwork units for the valley-side 1.5m cantilevered tunnel slab. In order to ensure that the total of 19 tunnel sections were completed on time and before winter set in, two standard 12m cycles were formed, reinforced and concreted per week on average. Hydraulic operations as well as the very light 35tonne construction weight resulted in a fast moving procedure on each occasion by means of heavy-duty rollers – in spite of the extremely steep incline of around 8% in this section of the route. In addition, the VARIOKIT formwork carriage could be easily adapted to the changing radii of the S-shaped gallery with the help of the integrated transverse launching units.

PERI delivered a wide range of prefabricated formwork and construction units to the job site which meant valuable time advantages could be achieved right at the beginning of this project. The planning and execution of the stopend formwork, including accommodation of the water stop, were said to be integral parts of PERI´s comprehensive overall solution. This meant numerous time-consuming working steps on the construction site could also be saved.