The construction of the world’s longest subsea road tunnel in Norway and a vital new link under the Bosphorus Strait in Turkey are among a host of exciting, major road tunnel-based projects currently being undertaken across the globe. Guy Woodford reports Sandvik DTi series tunnelling jumbos are being used for the excavation of Solbakktunnel, set to become the world’s longest subsea road tunnel.

The Sandvik DT1131i

RSSThe construction of the world’s longest subsea road tunnel in Norway and a vital new link under the Bosphorus Strait in Turkey are among a host of exciting, major road tunnel-based projects currently being undertaken across the globe. Guy Woodford reports

325 Sandvik DTi series tunnelling jumbos are being used for the excavation of Solbakktunnel, set to become the world’s longest subsea road tunnel.

Spanning 14.3km and part of the Ryfast megaproject in Norway, creating a ferry-free connection between the agricultural area of Nord Jæren and Ryfylke, the Solbakktunnel will consist of two two-lane 70.5m² wide tunnels. Excavation undertaken by project contractors Marti IAV Solbakk DA (Marti), a joint venture of Marti Contractors Ltd (Switzerland), Marti Norge (Norway) and IAV (Iceland), all part of Marti Group of Switzerland, will be around 1.2million m³. The Solbaktunnel’s steepest slope will be around 7%, the maximum gradient allowed. Another challenge for Marti is the project’s depth, as the deepest part of the tunnel will be 290m below sea level.

Solbakktunnel is one of the three Ryfast project tunnels. It will reduce travelling time between Nord Jæren and Ryfylke by two thirds. Around 4,000 cars a day are forecast to use the tunnel after its opening in around five years’ time, rising to 8,000 cars a day by 2035.

The whole Norwegian Highways Authority1208 Statens Vegvesen managed Ryfast project includes eight contracts, and the E02 for the Northern part of Solbakktunnel was awarded to Marti in May this year. The excavation works got underway at the beginning of August and are expected to last 39 months. The whole Ryfast project is due for completion in 2018.

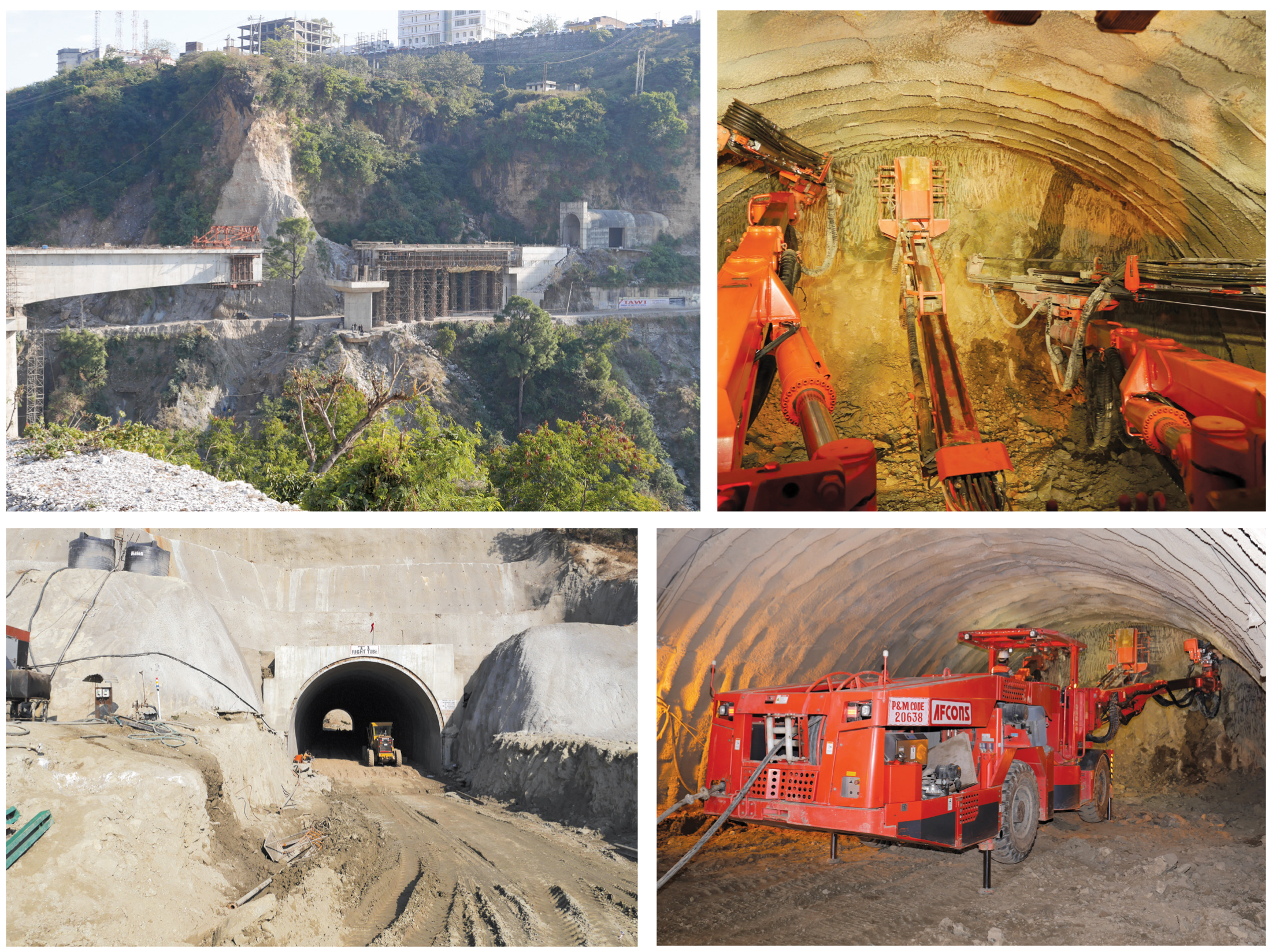

Marti is said to be using two DT1131i and two DT921i Sandvik tunnelling jumbos for the excavation of the Solbakktunnel because of their superior features and suitable delivery times. All four rigs are equipped with a profiling system from8003 Bever Control and Bever 3D Win Profiler, for scanning of the actual excavated tunnel section.

This allows controlling possible under and over break situations and optimising the process in order to improve the accuracy of excavation. One of the DT921li's also has a mechanised rod handling system, TRH, for long hole injection drilling.

The computer-controlled Sandvik DTi series tunneling jumbos are available in five models for excavation of 12-232m² Cross sections, including face drilling, bolt hole drilling, and mechanised long-hole drilling.

They feature an advanced iDATA control system, powerful high frequency RD525 rock drills, robust booms, advanced drill string guides, and FOPS-certified, spacious 3i cabins for ultimate usability and excellent working conditions. The DTis are meant for automatic use but allow the operator to fine-tune the process if the rock conditions so require.

Marti is a long-term customer for Sandvik. Currently they have, among other equipment, a Sandvik DT920i working at a site in Bhutan and two DT1230i's in the Holmestrand railway tunnel in Norway.

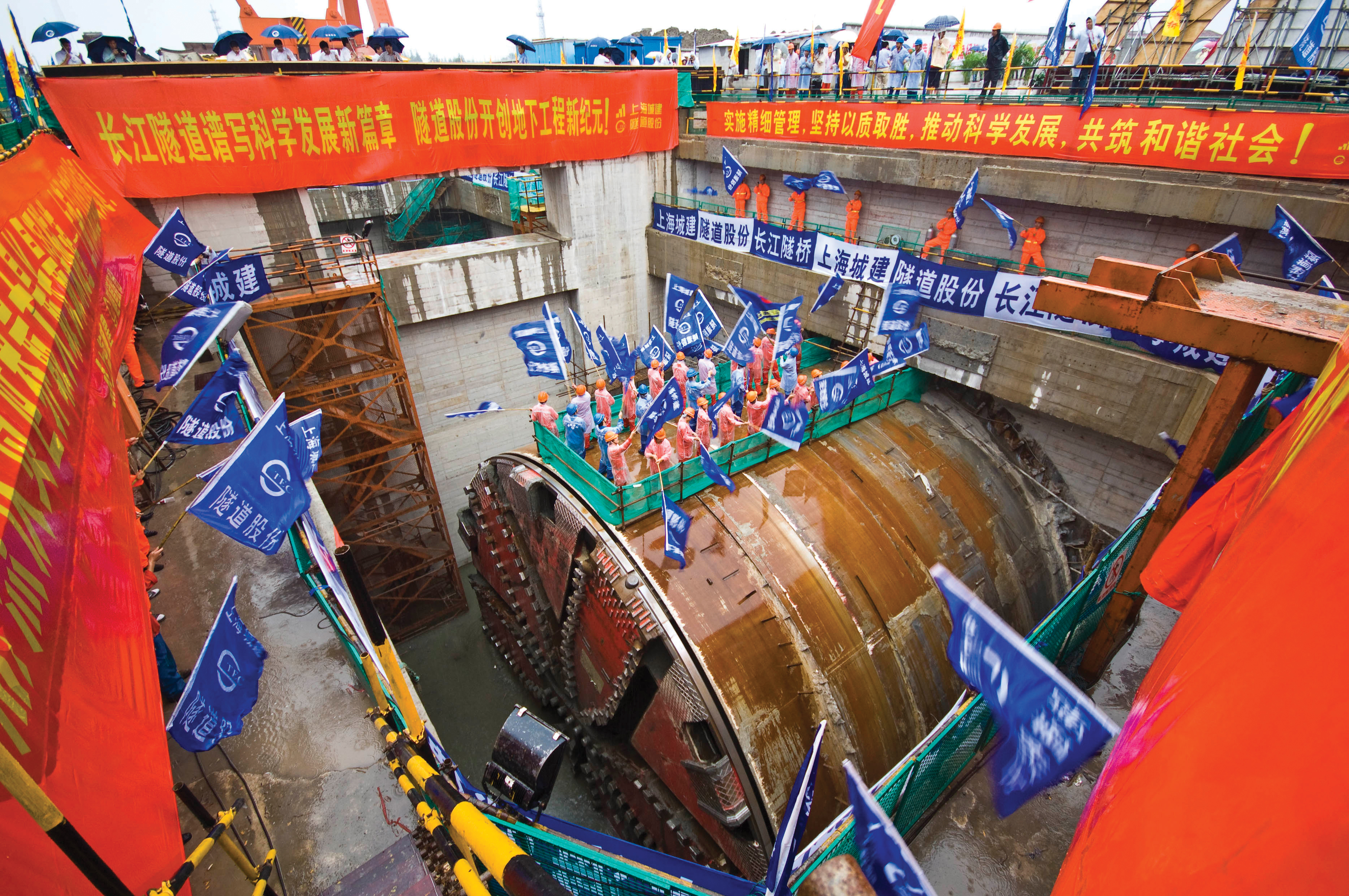

2592 Herrenknecht recently supplied a specially adapted Tunnel Boring Machine (TBM) to the construction consortium YMSK who are building a much needed new road tunnel under the Bosphorus Strait in Istanbul, Turkey.

The 13.6m TBM giant, a Mixshield, was completed in early July 2013 in Schwanau, Germany and been transported to the job site in Turkey.

The keenly awaited road tunnel will Cross beneath the Strait in Istanbul and expand the infrastructure bottleneck between Europe and Asia. The technical planning of the tunnelling operations is said by Herrenknecht to pose complex challenges, hence the construction consortium’s ordering of the bespoke TBM.

To get from the European to the Asian side of Istanbul, people and goods have to Cross the Bosporus Strait. So far, two road bridges as well as ferries provide the only transport link between the two parts of the city and the two continents. The tense traffic situation for nearly 14 million residents of the city and for international transit traffic should be improved considerably thanks to the construction of a new road tunnel under the Bosphorus.

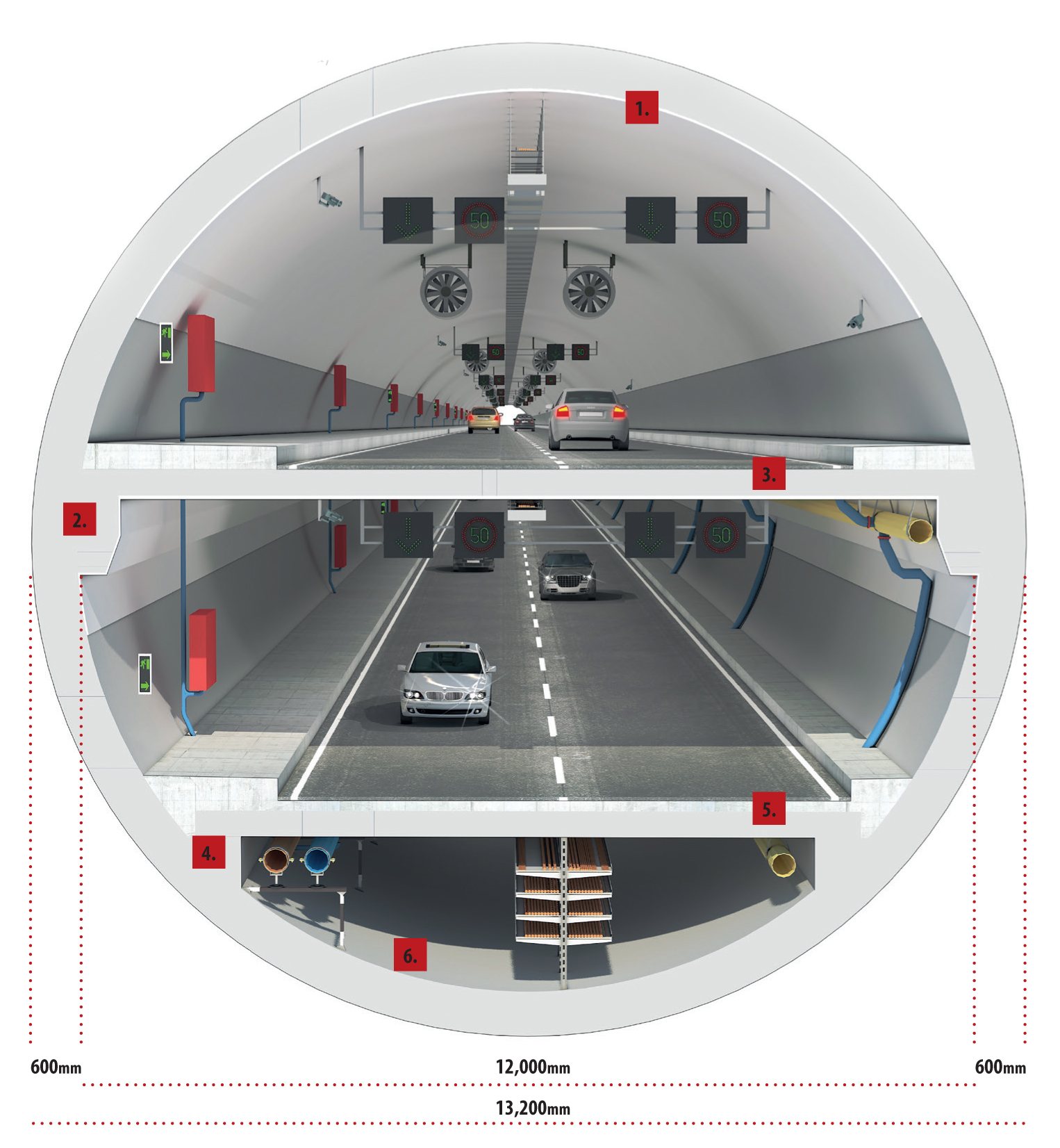

"The project is certainly one of the most challenging tunnelling operations currently being addressed in the world," said Herrenknecht project manager Georg Schleer. The route of the ‘Istanbul Strait Road Tube Crossing Project" runs around 100m below sea level at its deepest point. The interior diameter of the tunnel will be 12m so that two lanes in each direction can be accommodated. They will extend one above the other on two levels. Around 3.34km of the overall 5.4km tunnel are being created by the Herrenknecht TBM that will begin its underground mission from a launch shaft on the Asian side.

Extensive geological and hydrogeological preliminary investigations showed that YMSK, a Turkish-South Korean construction consortium consisting of Yapi Merkezi Insaat ve Sanayi and3093 SK Engineering & Construction, must contend with water pressures of up to 12bar.

"The machine's engineering presented us with a real challenge," said Schleer. "Even if the pressure is extremely high up front at the tunnel face, the client must be able to change the cutting tools quickly and safely if necessary.”

What Herrenknecht supplied YMSK was a new type of cutting wheel, where time- and cost-consuming access for maintenance work under pressurised air can be reduced. The complete cutting wheel is said to be accessible from the rear of the machine under atmospheric pressure. From there, all disc cutters and a large part of the cutting knives can be changed safely. Additionally, the Mixshield is equipped with a special, newly developed lock system. Herrenknecht says this allows pressurised air access at well over 5bar where necessary.

To detect strong material wear early and to tackle necessary maintenance access in a targeted manner, wear detectors are integrated into the excavation tools as well as in the steel construction of the cutting wheel. Moreover, the disc cutters are equipped with the DCRM monitoring system (Disc Cutter Rotation Monitoring), which was developed by Herrenknecht. It provides data about the rotational movement and temperature of the disc cutters in real-time to the machine operator in the control container. Thus, conclusions can be drawn regarding the condition of the tools and change intervals can be better planned.

In the Herrenknecht factory in Schwanau the Mixshield was named Yildirim Bayezid, after a sultan who led the expansion of the Ottoman Empire at the end of the 14th Century. After its factory dismantling, transport, and assembly at the job site, the Herrenknecht Mixshield will start its tunnelling work in Istanbul at the end of 2013.

Following the opening of the tunnel, the new quick link between Europe and Asia will initially be operated for 26 years by the joint venture Avrasya Tüneli Isletme Insaat ve Yatirim A.S. (ATAS) and subsequently handed over to the Istanbul government.

The Bosphorus Strait was crossed with a TBM for the first time in 2008-2009. An Earth Pressure Balance Shield (Ø 6,110mm) from Herrenknecht was used for the construction of a water tunnel.

In the United States,203 Doka’s biggest ever SL-1 tunnel project - the Second Midtown Tunnel linking the cities of Norfolk and Portsmouth in the state of Virginia – will need to be finished underwater.

The 1.13km long immersed tunnel has 11 separate segments currently being cast at a dry dock in Baltimore, Maryland, after which they will be floated about 320km south to the Elizabeth River and lowered to the riverbed. The heavy-duty supporting system SL-1 tunnel formwork that Doka is supplying to the project is said by the Austrian firm to be a high-performing yet cost-saving solution. It is the first time the formwork type has been used in the US.

Norfolk and Portsmouth have been linked beneath the Elizabeth River since the building of an underwater tunnel just over 50 years ago. Carrying around a million vehicles per month, the transport artery is one of the busiest routes east of the Mississippi. Chronic congestion in and around the two-lane tunnel, and long journey times, are the norm. To relieve this situation, the old Midtown Tunnel is to be rehabilitated and a new two-lane immersed tunnel built alongside it. Together with the existing tunnel, the Second Midtown Tunnel will double traffic capacity on this route.

Doka supplied a custom-built SL-1 formwork solution for a similar project in 2005: the 3km-long Busan-Geoje Fixed Link is one of the deepest immersed tunnels in the world and connects South Korea’s second-largest city, Busan, to the island of Geoje at a depth of up to 60m.

The 1.13km-long Second Midtown Tunnel will include eleven separate segments, each measuring around 106m long, 16m wide and 8.8m tall. Each segment weighs nearly 13,000tonnes and is being precast in a dry dock in Baltimore, Maryland. The finished segments will then embark on an approximate 320km southbound voyage, being floated down Chesapeake Bay on giant barges to the immersion site in Norfolk. Here, the tunnel segments will be fixed together underwater and sealed with rubber seals. This special system, and the use of watertight concrete, make the Second Midtown Tunnel only the second such tunnel in the whole US not to need an external steel skin.

At the dry dock, the preassembly work on the Doka tunnel formwork traveller was completed at the beginning of 2013 and the first trial pours are now being carried out. From June onward, the tunnel segments will enter ‘series production’. Until April 2014, preparations at the tunnel site under the Elizabeth River will remain in full swing. The riverbed around the tunnel will be dredged into shape so that the segments can be lowered into place on schedule between November 2014 and November 2015. Upon its completion in September 2016, the Second Midtown Tunnel will get traffic flowing smoothly again across the bed of the Elizabeth River.

The heavy-duty supporting system SL-1 tunnel formwork chosen by the contractors, SKW Constructors, a consortium of2296 Skanska, Kiewit and Weeks, is fully compatible with large-area formwork Top 50. The flexible system accommodates any architectural requirement and, according to Doka, saves craneage because of its large gang-forms. The element joints are designed to ensure a perfect joint pattern. On the Second Midtown Tunnel, the high-load components allow the use of a hydrostatic design basis for the centre wall of the tunnel segments. This makes rapid pouring possible, with no need to worry about the rate of placing. Doka says the stringent requirements applying to the implementation of the project have called for detailed preparations and strong teamwork from the international experts involved. To achieve the best possible exchange of expertise, a member of the SKW Constructors team spent several weeks at Doka HQ in Amstetten, Austria during the planning phase, to work with the specialists from the firm’s Tunnel Competence Centre on identifying the right solution.

Regular face-to-face meetings, as well as telephone and video conferences, between Doka’s Tunnel Competence Centre team and project leaders are said to be ensuring that despite the great distances, the project is carried out in the best and most effective way, from the planning phase through until completion.

7536 FLIR Intelligent Transportation Systems recently landed a contract to equip both the Prado Carénage Tunnel and the Prado Sud Tunnel in Marseille, France with AID technology.

The 2.5km-long Prado Carénage Tunnel allows you to easily and quickly Cross the city of Marseille without leaving the motorway. The Tunnel Prado Carénage connects the southern districts of the city of Marseille and the eastern motorway to the city centre and to the north via the Vieux Port tunnel and the coastal motorway.

The 1,500m double-deck Prado Sud tunnel, each with two lanes, will extend the existing Prado Carénage tunnel towards the southern part of the city. The tunnel is scheduled to open in 2014.

For this project, FLIR is offering a complete detection and monitoring solution, including automatic incident detection, surveillance cameras, mobile cameras, recording capabilities and visualisation. With the addition of this contract, FLIR technology is now monitoring all current tunnels in the city of Marseille.

Some 57 cameras in the Prado Sud tunnel and 95 cameras in the Prado Carénage tunnel are monitoring traffic for all types of incidents, including stopped vehicles, wrong way drivers, pedestrians and smoke. All this information, provided by a combination of cameras and encoders, is collected and managed by the Flux video detection management system.

Flux collects traffic data, events, alarms and video images generated by the video detectors. The main goal of Flux is to manage and control all traffic information generated by these various detectors and to make it useful, meaningful and relevant to the user. Flux provides a user-friendly interface composed of a monitoring and a reporting application and enables real-time monitoring of events and alarms.RSS

Spanning 14.3km and part of the Ryfast megaproject in Norway, creating a ferry-free connection between the agricultural area of Nord Jæren and Ryfylke, the Solbakktunnel will consist of two two-lane 70.5m² wide tunnels. Excavation undertaken by project contractors Marti IAV Solbakk DA (Marti), a joint venture of Marti Contractors Ltd (Switzerland), Marti Norge (Norway) and IAV (Iceland), all part of Marti Group of Switzerland, will be around 1.2million m³. The Solbaktunnel’s steepest slope will be around 7%, the maximum gradient allowed. Another challenge for Marti is the project’s depth, as the deepest part of the tunnel will be 290m below sea level.

Solbakktunnel is one of the three Ryfast project tunnels. It will reduce travelling time between Nord Jæren and Ryfylke by two thirds. Around 4,000 cars a day are forecast to use the tunnel after its opening in around five years’ time, rising to 8,000 cars a day by 2035.

The whole Norwegian Highways Authority

Marti is said to be using two DT1131i and two DT921i Sandvik tunnelling jumbos for the excavation of the Solbakktunnel because of their superior features and suitable delivery times. All four rigs are equipped with a profiling system from

This allows controlling possible under and over break situations and optimising the process in order to improve the accuracy of excavation. One of the DT921li's also has a mechanised rod handling system, TRH, for long hole injection drilling.

The computer-controlled Sandvik DTi series tunneling jumbos are available in five models for excavation of 12-232m² Cross sections, including face drilling, bolt hole drilling, and mechanised long-hole drilling.

They feature an advanced iDATA control system, powerful high frequency RD525 rock drills, robust booms, advanced drill string guides, and FOPS-certified, spacious 3i cabins for ultimate usability and excellent working conditions. The DTis are meant for automatic use but allow the operator to fine-tune the process if the rock conditions so require.

Marti is a long-term customer for Sandvik. Currently they have, among other equipment, a Sandvik DT920i working at a site in Bhutan and two DT1230i's in the Holmestrand railway tunnel in Norway.

The 13.6m TBM giant, a Mixshield, was completed in early July 2013 in Schwanau, Germany and been transported to the job site in Turkey.

The keenly awaited road tunnel will Cross beneath the Strait in Istanbul and expand the infrastructure bottleneck between Europe and Asia. The technical planning of the tunnelling operations is said by Herrenknecht to pose complex challenges, hence the construction consortium’s ordering of the bespoke TBM.

To get from the European to the Asian side of Istanbul, people and goods have to Cross the Bosporus Strait. So far, two road bridges as well as ferries provide the only transport link between the two parts of the city and the two continents. The tense traffic situation for nearly 14 million residents of the city and for international transit traffic should be improved considerably thanks to the construction of a new road tunnel under the Bosphorus.

"The project is certainly one of the most challenging tunnelling operations currently being addressed in the world," said Herrenknecht project manager Georg Schleer. The route of the ‘Istanbul Strait Road Tube Crossing Project" runs around 100m below sea level at its deepest point. The interior diameter of the tunnel will be 12m so that two lanes in each direction can be accommodated. They will extend one above the other on two levels. Around 3.34km of the overall 5.4km tunnel are being created by the Herrenknecht TBM that will begin its underground mission from a launch shaft on the Asian side.

Extensive geological and hydrogeological preliminary investigations showed that YMSK, a Turkish-South Korean construction consortium consisting of Yapi Merkezi Insaat ve Sanayi and

"The machine's engineering presented us with a real challenge," said Schleer. "Even if the pressure is extremely high up front at the tunnel face, the client must be able to change the cutting tools quickly and safely if necessary.”

What Herrenknecht supplied YMSK was a new type of cutting wheel, where time- and cost-consuming access for maintenance work under pressurised air can be reduced. The complete cutting wheel is said to be accessible from the rear of the machine under atmospheric pressure. From there, all disc cutters and a large part of the cutting knives can be changed safely. Additionally, the Mixshield is equipped with a special, newly developed lock system. Herrenknecht says this allows pressurised air access at well over 5bar where necessary.

To detect strong material wear early and to tackle necessary maintenance access in a targeted manner, wear detectors are integrated into the excavation tools as well as in the steel construction of the cutting wheel. Moreover, the disc cutters are equipped with the DCRM monitoring system (Disc Cutter Rotation Monitoring), which was developed by Herrenknecht. It provides data about the rotational movement and temperature of the disc cutters in real-time to the machine operator in the control container. Thus, conclusions can be drawn regarding the condition of the tools and change intervals can be better planned.

In the Herrenknecht factory in Schwanau the Mixshield was named Yildirim Bayezid, after a sultan who led the expansion of the Ottoman Empire at the end of the 14th Century. After its factory dismantling, transport, and assembly at the job site, the Herrenknecht Mixshield will start its tunnelling work in Istanbul at the end of 2013.

Following the opening of the tunnel, the new quick link between Europe and Asia will initially be operated for 26 years by the joint venture Avrasya Tüneli Isletme Insaat ve Yatirim A.S. (ATAS) and subsequently handed over to the Istanbul government.

The Bosphorus Strait was crossed with a TBM for the first time in 2008-2009. An Earth Pressure Balance Shield (Ø 6,110mm) from Herrenknecht was used for the construction of a water tunnel.

In the United States,

The 1.13km long immersed tunnel has 11 separate segments currently being cast at a dry dock in Baltimore, Maryland, after which they will be floated about 320km south to the Elizabeth River and lowered to the riverbed. The heavy-duty supporting system SL-1 tunnel formwork that Doka is supplying to the project is said by the Austrian firm to be a high-performing yet cost-saving solution. It is the first time the formwork type has been used in the US.

Norfolk and Portsmouth have been linked beneath the Elizabeth River since the building of an underwater tunnel just over 50 years ago. Carrying around a million vehicles per month, the transport artery is one of the busiest routes east of the Mississippi. Chronic congestion in and around the two-lane tunnel, and long journey times, are the norm. To relieve this situation, the old Midtown Tunnel is to be rehabilitated and a new two-lane immersed tunnel built alongside it. Together with the existing tunnel, the Second Midtown Tunnel will double traffic capacity on this route.

Doka supplied a custom-built SL-1 formwork solution for a similar project in 2005: the 3km-long Busan-Geoje Fixed Link is one of the deepest immersed tunnels in the world and connects South Korea’s second-largest city, Busan, to the island of Geoje at a depth of up to 60m.

The 1.13km-long Second Midtown Tunnel will include eleven separate segments, each measuring around 106m long, 16m wide and 8.8m tall. Each segment weighs nearly 13,000tonnes and is being precast in a dry dock in Baltimore, Maryland. The finished segments will then embark on an approximate 320km southbound voyage, being floated down Chesapeake Bay on giant barges to the immersion site in Norfolk. Here, the tunnel segments will be fixed together underwater and sealed with rubber seals. This special system, and the use of watertight concrete, make the Second Midtown Tunnel only the second such tunnel in the whole US not to need an external steel skin.

At the dry dock, the preassembly work on the Doka tunnel formwork traveller was completed at the beginning of 2013 and the first trial pours are now being carried out. From June onward, the tunnel segments will enter ‘series production’. Until April 2014, preparations at the tunnel site under the Elizabeth River will remain in full swing. The riverbed around the tunnel will be dredged into shape so that the segments can be lowered into place on schedule between November 2014 and November 2015. Upon its completion in September 2016, the Second Midtown Tunnel will get traffic flowing smoothly again across the bed of the Elizabeth River.

The heavy-duty supporting system SL-1 tunnel formwork chosen by the contractors, SKW Constructors, a consortium of

Regular face-to-face meetings, as well as telephone and video conferences, between Doka’s Tunnel Competence Centre team and project leaders are said to be ensuring that despite the great distances, the project is carried out in the best and most effective way, from the planning phase through until completion.

The 2.5km-long Prado Carénage Tunnel allows you to easily and quickly Cross the city of Marseille without leaving the motorway. The Tunnel Prado Carénage connects the southern districts of the city of Marseille and the eastern motorway to the city centre and to the north via the Vieux Port tunnel and the coastal motorway.

The 1,500m double-deck Prado Sud tunnel, each with two lanes, will extend the existing Prado Carénage tunnel towards the southern part of the city. The tunnel is scheduled to open in 2014.

For this project, FLIR is offering a complete detection and monitoring solution, including automatic incident detection, surveillance cameras, mobile cameras, recording capabilities and visualisation. With the addition of this contract, FLIR technology is now monitoring all current tunnels in the city of Marseille.

Some 57 cameras in the Prado Sud tunnel and 95 cameras in the Prado Carénage tunnel are monitoring traffic for all types of incidents, including stopped vehicles, wrong way drivers, pedestrians and smoke. All this information, provided by a combination of cameras and encoders, is collected and managed by the Flux video detection management system.

Flux collects traffic data, events, alarms and video images generated by the video detectors. The main goal of Flux is to manage and control all traffic information generated by these various detectors and to make it useful, meaningful and relevant to the user. Flux provides a user-friendly interface composed of a monitoring and a reporting application and enables real-time monitoring of events and alarms.RSS