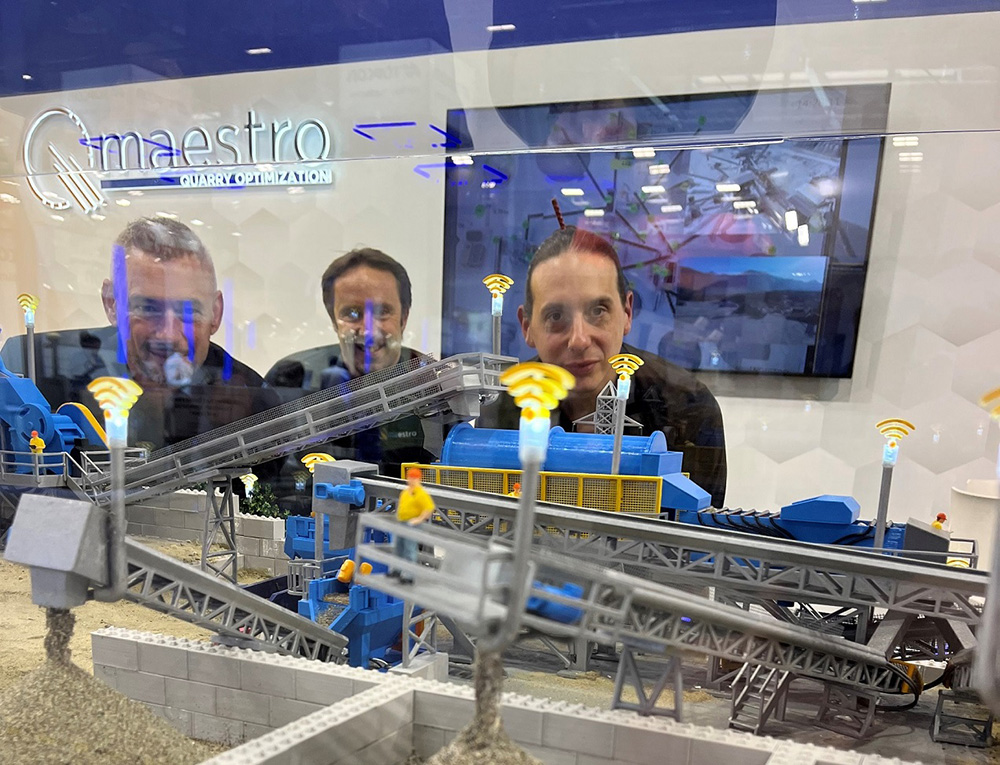

Ma-estro turns quarry operators into skilled Q-PILOTS

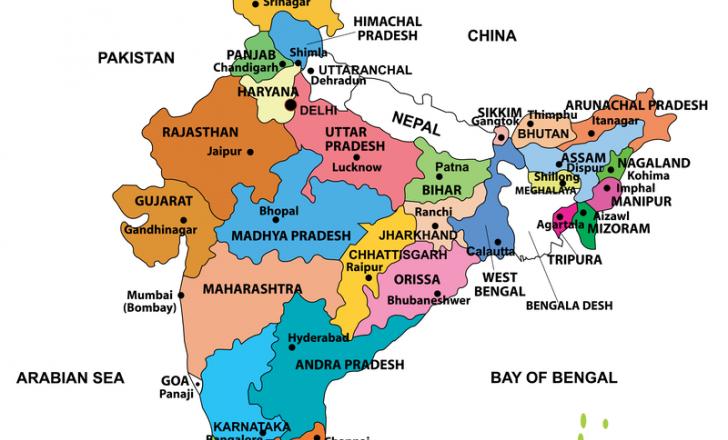

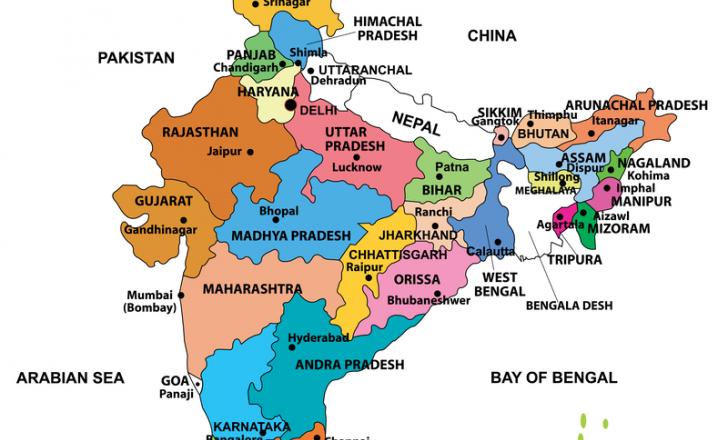

Expressway planned for India’s Odisha State

Loan to boost key Nepal road works

Strong export performance for XCMG

Indian ring road project awarded

Indian highway corridor works

Indian road projects underway

Indian highway widening planned

Indian highway deal signed

India-China border roads programme

Bonjour bio-based binders

Bay Shore launches Drill Sergeant X excavator attachment for greater reach and swing

The DSX can be used in a range of applications from core drilling to signposts, pedestrian bridges, overpass bridges, light poles and street lighting.

According to Josh Keough, southeast US sales manager for Bay Shore Systems, the new system will be available in the US as well as India, Russia, Australia and Mexico (where it has two representatives).

Bay Shore Systems started in 1978 as a family-owned manufacturer of foundation drilling equipment. Originally based in the San Francisco Bay Area, the relocated to Rathdrum, Idaho, in 1996. It also has a manufacturing and service facility in London, Kentucky.

Improving Rutting with Sripath’s PGXpand® PMB-Mixes

Komatsu buying German firm GHH

Indian highway deals for Bihar State

Bangladesh highway contract awarded

Caterpillar highlights prototype batteries for off-highway equipment

Leveraging expertise across the construction, quarrying and mining equipment giant’s global network of technical centres in the US, UK, China and India, the programme focuses initially on battery solutions for equipment used predominantly in industrial applications.

The battery range, currently in prototype form, uses lithium-ion technology and features a modular design to optimise performance and packaging.

They have also been engineered with sustainability in mind throughout their lifecycle, with the potential to reuse and recycle the units at the end of their life.

The development programme also encompasses inverters, motors, electronic controls, digital services, and other critical technologies to deliver the performance, reliability, durability, maintainability, and long-term value needed for equipment buyers working in harsh operating environments.

“Caterpillar has demonstrated a long-standing commitment to sustainability through improvements in our operations and by helping our customers achieve their climate-related goals,” said Steve Ferguson, senior vice president Caterpillar Industrial Power Systems.

“Our battery programme is our latest step in combining a wide-ranging inventory of innovations with extensive knowledge of the off-highway industry to offer solutions for a range of power needs, application types, duty cycles and operating environments.”

Caterpillar has committed that 100% of its new products through 2030 will be more sustainable than the previous generation, which is reflected in the company’s line-up of industrial-power solutions and integrated services finely tuned for owners of third-party equipment powered by Cat engines.

“Improved sustainability is a journey, not a destination, and one size doesn’t fit all in determining the appropriate power solution for equipment owners,” continued Ferguson.

“Our offerings can help customers and end users start improving the sustainability of their operations today through high-efficiency engines, fuels and digital solutions now available for the jobsite, by extending value and reducing waste over the lifecycle of equipment they already own, and by powering the next generation of equipment with innovations precisely configured for the jobsite.”

Engines, Components & Tyres

Engines, Components & Tyres

Shell and CRH in decarbonisation agreement