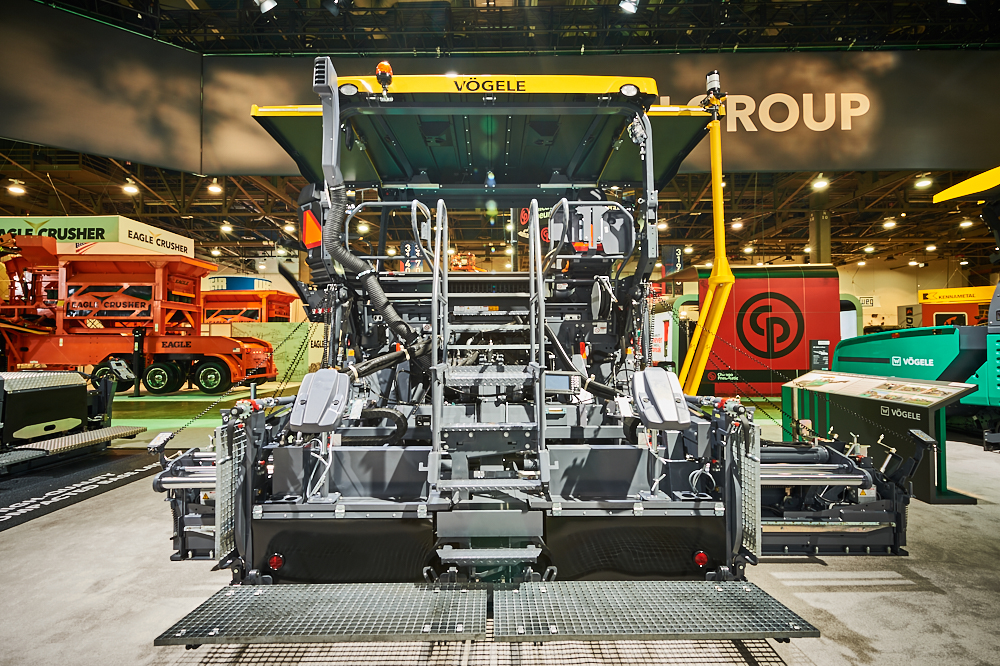

The 2.4m Super 1700-3i and Super 1703-3i can cover a wide range of road construction applications. When combined with the Vögele front-mounted extending screed and hydraulic bolt-on extensions they provide a maximum paving width of up to 5.95m. A 129kW Cummins engine delivers the power to perform at full width and, when running in ECO mode, offers reduced noise emissions and fuel consumption.

The material handling system of these pavers is designed for high output, with separate hydraulic drives on the conveyor and the auger. Available with 6x4 or 6x6 drive, the Super 1700-3i and Super 1703-3i can deliver paving rates of up to 700 tonnes/hour.

The Super 2000-3i and Super 2003-3i come with the latest version of Vögele’s ErgoPlus 3 operating system. The highway class pavers can be combined with a VF600 screed with front-mounted extensions, or the VR600 and AB600 rear-mounted screeds with extensions. The AB600 is equipped with both a vibrating system and a tamper.

The two larger models are powered by a 186kW Cummins engine and can handle up to 1,400 tonnes/hour of material. The VF600 screed with unequal-width extensions is available for paving widths up to 7.75m, while rear-mounted extensions take that to 8.6m for the Super 2000-3i and 7.3m for the Super 2003-3i. The larger machines can also be equipped with an AB600 screed with rear-mounted extensions. This achieves higher compaction rates thanks to tamper and vibration systems, making the machines particularly suited to placing cold RAP (Reclaimed Asphalt Pavement).