The North American paving equipment market is now benefiting from a series of new machines being introduced to the market. Throughput, paving quality and machine reliability have all benefited from the use of the latest technology by key manufacturers.

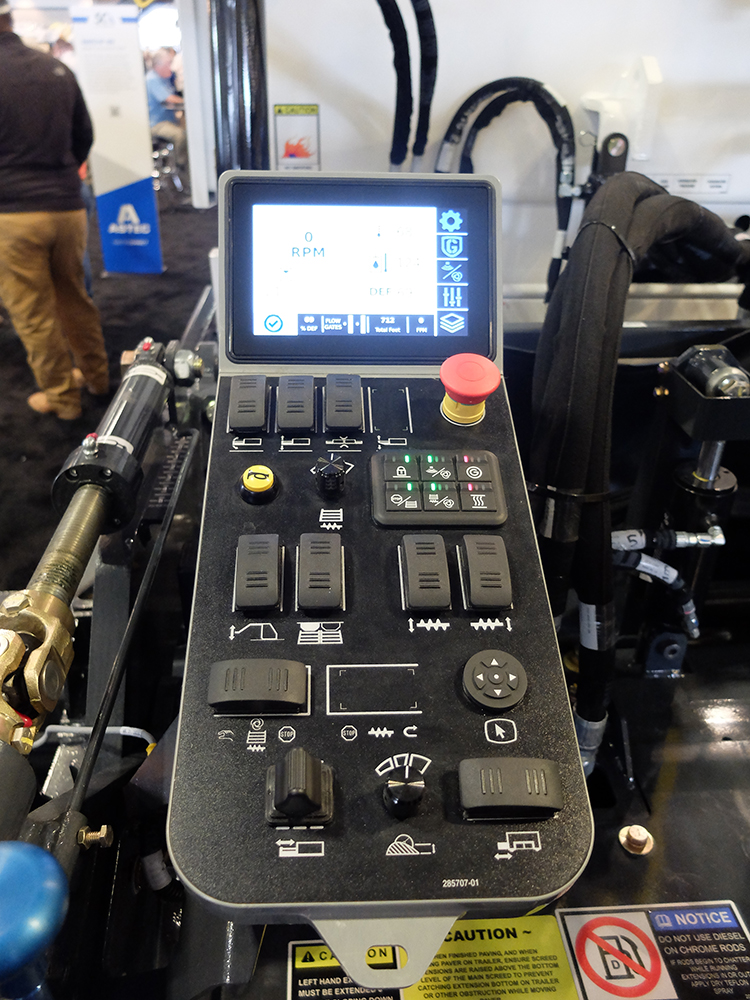

Astec is upgrading its Roadtec RP-series highway class asphalt pavers with a new operator control system. The firm’s highway class asphalt pavers are equipped with a digital control system and easy-to-understand touchscreen interface. These advanced updates deliver a balance of intuitive technology and simplified operation, providing the durability and serviceability Astec customers expect.

Keith Hagy, Product Manager for Astec paving products, explains, “By listening to our customers, we developed a highly functional, technologically-advanced control system that is still simple to operate and service.”

The ergonomic control system is said to be reliable and easy-to-service, with digital icons allowing operators to monitor machine status

The RP-series highway class pavers will continue to be manufactured with the same trusted machine features and will now include the upgraded control panel technology standard on all models.

A number of improvements have also been made to the Shuttle Buggy material transfer vehicle. Internal components have been improved to boost working life, reducing maintenance costs as well as downtime. Capacity has been increased while the remixing technology also has been upgraded to ensure greater homogeneity of the mix as it leaves the machine. Power now comes from the latest Cummins QSB6.7 diesel, which meets Tier 4 Final emissions requirements.

Meanwhile, Caterpillar’s latest AP455 machine slots into the range between the firm’s small pavers and highway class pavers for the firm’s North American range. Power comes from the Cat C3.6 diesel rated at 90kW and which meets Tier 4 Final emissions requirements. Paving performance has been prioritised and a spokesperson for the firm said, “It has our new SE47 screed.”

The SE47 screed is offered with front and rear mount variants and offers operating widths from 2.4-4.7m although 5.94m widths can be achieved using extensions.

Features include the same proportional controls as the firm’s larger machines, while the Pave Start Assistant system ensures that the machine will restart working after a break at the same settings as previously to ensure quality. On the deck the paver has two sing-out seats allowing good views over the screed, with a single control panel that can be slid to either position as required. The lower platform is said to offer good visibility and while the machine is around 127mm shorter than its predecessor, it is more manoeuvrable with longer, low profile tracks and a better weight distribution for improved stability. The conveyor chain is also longer, improving material transport from the hopper and preventing build-ups around the edges.

Dynapac is offering a new range of highway class pavers and screeds for North America, including four new tractors and two screeds. The D25T and D25W are similar models running on tracks and wheels respectively and suited to use with the Mat Master 16R screed offering paving widths from 2.44-4.88m. The D30T and D30W are similar models running on tracks and wheels respectively and suited to use with the Mat Master 20R screed offering paving widths from 3.05-6.1m.

Fast heating times are claimed for both screeds. The Mat Master screed design is said to avoid bending or torsion with its novel double extension system, while high pre-compaction is achieved with its heavyweight design. A heat control system delivers a quality mat with consistent heat distribution while a positive lock thread mechanism avoids the need of constant screed adjustment during paving.

According to Dynapac, these new generation pavers can be used for a range of tasks and offer high paving speeds for thin or thick layers, providing high productivity and uptime. High transportation speeds of up to 16km/h allow fast repositioning, while the iTrack rubber tracks offer high performance, long wear life and low maintenance costs. A sophisticated intelligent track system is said to identify incorrect tension, reducing downtime. The dynamic suspension control (DSC) on the wheel pavers boost tractive effort. The Mat Master screeds are equipped with DiveStop and Active Screed Assist technique for high paving productivity and efficiency. The DiveStop system prevents the screed from dropping at the end of a paving job, instead raising the screed to avoid leaving marks on the mat as well as avoiding crushing aggregates on thin wearing courses. The novel double width heavy-duty screed design is suitable for paving work with fewer passes. A spokesperson commented, “It’s a very heavy-duty screed design.”

The machines also benefit from the PaveSmart system originally developed for Dynapac’s European pavers, which improves control and allows a user to collate operating data for reports. Off-the-shelf levelling and paving systems can be used from Leica Geosystems, Moba, Topcon and Trimble. Also fitted from the European pavers is the safe impact system.

Other benefits include dual consoles with the Dynapac smart, swing-out dashboard and operator assist functions such as FeedAssist, CleanAssist, ImpactAssist, and LightAssist, as well as a feed system designed to provide multiple options.

The main wear parts on the new range of pavers such as push rollers, conveyor and auger wear parts designed to extend the component life. The U-shape screed plate is designed for longer life, while the ground engaging parts also offer long intervals between rebuilds.

A flicker-free generator system design makes night paving easier and allows lighting to be connected directly to the paver. In addition, the ECO-Mode engine reduces fuel consumption and allows the paver to operate at low engine RPM.

Meanwhile, Dynapac is also offering its improved MF2500CS mobile feeder, featuring the novel IMIX system, featuring a versatile belt technology, intelligent operator assistance and the ability to configure the machine for each application.

The IMIX technology reduces the risk of material segregation, in which larger material moves to the outer sections, while smaller material settles in the middle of the material flow. The IMIX-system uses a conical auger in the hopper, a flow divider in the conveyor and a mixing system at the end of the main conveyor. The augers in the hopper push the large particles at the colder outer sections on the hopper towards the middle of the conveyor to join the main flow. Material is transported by the belt to the top, where the flow of material is split by a flow divided into two streams that are mixed and blended at the end of the conveyor by another auger before leaving the main conveyor.

This system ensures homogenous temperatures and an even mix of stone sizes for longer lasting road surfaces. The feeder’s rubber belt is mounted directly on metal stiffeners, allowing longer intervals between belt changes and higher reliability.

For longer uptime, the rubber belt connection has been optimised, and testing in varying conditions with various mixes shows improved stability. The repositioned spraying beam under the front hopper flap ensures a wet feeder belt, preventing adhesion with difficult mixes and weather conditions.

The Dynapac MF2500CS can be used for transferring a variety of materials such as asphalt, RCC, aggregate or sand. For large paving widths, the Dynapac MF2500 delivers a feeding capacity of up to 3,600tonnes/hour.

The Truck Assist feature improves truck docking/undocking. A series of LED bar lights signals the truck driver when to back up, dump the material and when to leave.

The MF2500CS can be equipped with the SW6500 SwingApp conveyor for long side reach for paving over barriers and in-line or echelon paving applications. The newly-developed 8.5m long SW6500 conveyor has a side reach of 3.8m and can be mounted behind any MF2500CS within 20 minutes.

A distance assistance system maintains a safe distance between the material feeder and paver. The package includes a laser sensor, which allows the feeder operator to connect to the paver and follow the speed of the paver movement.