Engines and drivelines technologies have move forward, as could be seen at Conexpo 2014 - Geoff Ascroft reports

Solutions for Tier 4 Final emissions regulations dominated Conexpo 2014, with many firms showing off their options of DOC, DPF and SCR after-treatments.

Deutz, while staying with an SCR-only solution, took a more unusual approach on its high horsepower V6 12litre and V8 16litre engines. Both get a dual SCR after treatment system to meet Tier 4 Final emission standards. Using a dual SCR system,

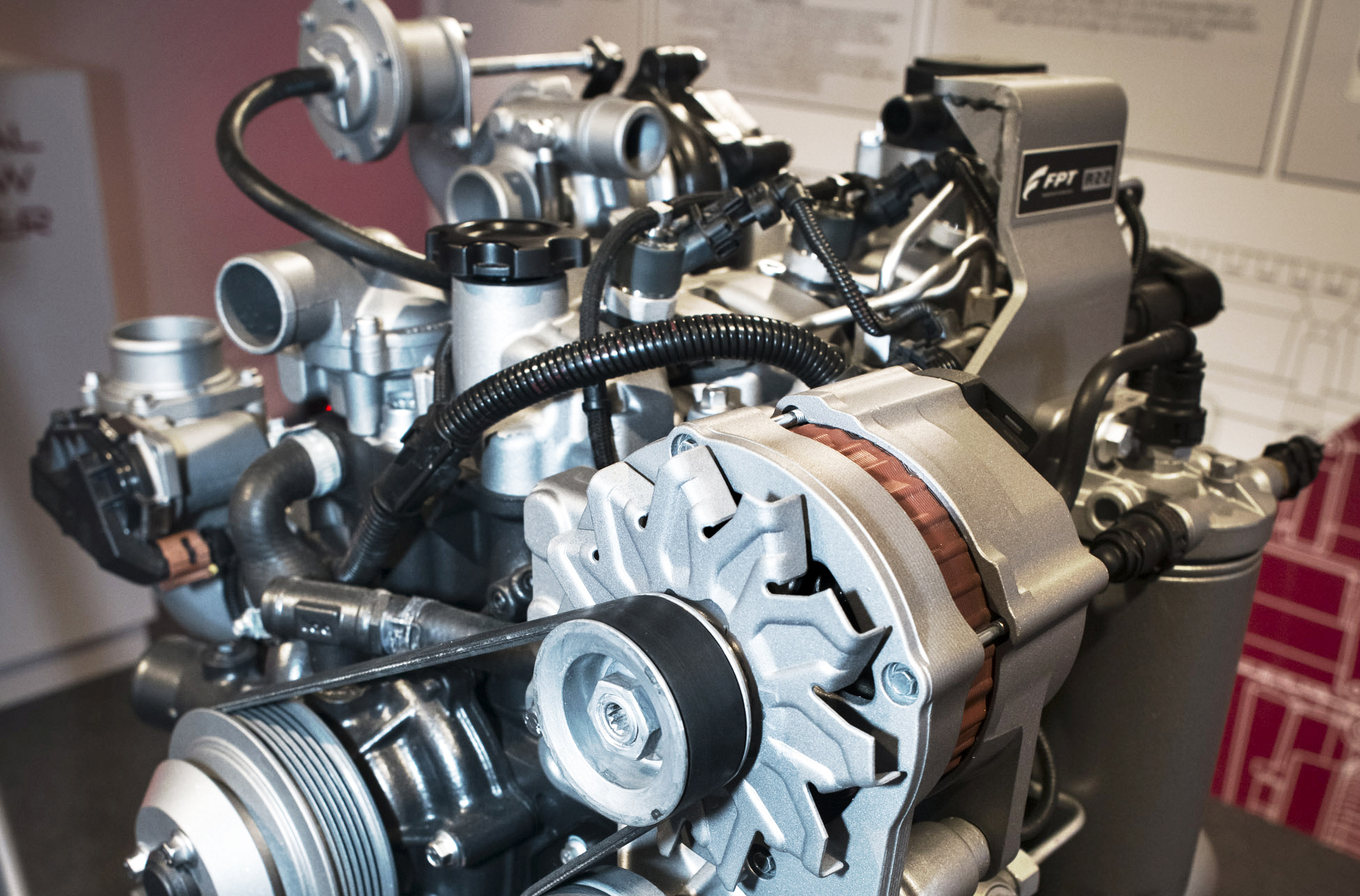

PT's compact, three cylinderR22 diesel delivers up to 52kW

Engines and drivelines technologies have move forward, as could be seen at Conexpo 2014 - Geoff Ascroft reports

Solutions for Tier 4 Final emissions regulations dominated3485 Conexpo 2014, with many firms showing off their options of DOC, DPF and SCR after-treatments.

201 Deutz, while staying with an SCR-only solution, took a more unusual approach on its high horsepower V6 12litre and V8 16litre engines. Both get a dual SCR after treatment system to meet Tier 4 Final emission standards. Using a dual SCR system, the water-cooled 90-degree V6 and V8 engines with power outputs from 390-520kW, do not need to use cooled EGR, DOC or DPF technologies. Compared to a similar engine using cooled EGR, Deutz said its V6 and V8 engines can be installed with a cooling package that is around 20-25% smaller, improving packaging for OEMs.

Deutz’s SCR package uses a combined DOC/SCR catalyst as the first phase of exhaust treatment, followed by a ‘clean-up’ catalyst. While slightly bulkier than a single SCR system, the dual SCR package uses one tank and two dosing systems, but does not use twice as much fluid, said the company. Expect diesel exhaust fluid consumption to increase by 2%, said the company. Despite the increased fluid consumption for after-treatment, the Deutz V6 and V8 engines are said to offer up to 8% more performance with average fuel consumption reduced by around 5% compared to the previous Tier 4 interim versions.

196 Cummins latest global engine platform, the QSG12, offers power outputs up to 382kW for heavy-duty applications. The six-cylinder, 12-litre engine is purpose-designed to meet US EPA Tier 4 Final near-zero emissions regulations with a more compact envelope and over 30 per cent higher power-to-weight ratio than the class average for engines with a similar power range.

Importantly, the QSG12 brings a major advantage for Tier 4 Final equipment installations by restoring the envelope size of its QSM11 predecessor, which was used for Tier 3 applications. Higher efficiency air handling and advanced combustion enable the QSG12 to return to the simplicity of a wastegated turbocharger and achieve near-zero emissions without the need for a cooled exhaust gas recirculation (EGR) system.

As a result, internal loads on the QSG12 are reduced, said Cummins, to free up extra power potential, while heat rejection is lowered by over 40% compared with engines using cooled EGR.

With Cummins partnering with driveline specialist7214 Oerlikon for a hybrid electric drive project for wheeled loaders, the QSG12 engine has been chosen as a fuel-efficient power unit that could lead to fuel savings of up to 30%.

The hybrid package is a complete electric driveline system. It starts with the 12litre QSG engine that carries a reluctance-type motor/generator to produce electrical power. This electrical energy is used to drive the wheels through individual high power electric wheel motors.

Oil-cooled 65kW switch reluctance wheel motors contain a single-speed gearbox, creating a 100:1 reduction to transfer electrical power into high torque wheel drive. Each wheel motor’s gearbox contains park and service brakes, and allows regenerative energy recovery under braking – Ideal for repetitive duties performed by wheeled loaders. An ultra-capacitor bank is used to store and release electrical energy on-demand.

While the system is still in the development stages, Cummins engineers expect the QSG engine to operate as a constant speed engine, in a sweet spot of around 1,200rpm while delivering 298kW. The hybrid system is currently being installed in the LW900K - a 30tonne class2490 XCMG wheeled loader - and is expected to be unveiled as a working prototype in November 2014 at 5930 Bauma China.

Oerlikon expects the hybrid system to be lighter in overall weight to conventional driveline components. Further benefits of such a system, said the company, is that the compact wheel motor design used by the hybrid driveline could eventually lead to the development of independent suspension for wheeled loaders.

With Tier 4 Final in mind, Cummins’ Emissions Solutions division has introduced a range of EcoFit urea tanks and lines for those adopting SCR after-treatment systems. EcoFit includes four tank capacities – 19, 38, 57 and 114litres – including two different shape profiles for additional installation flexibility. The portfolio also includes electrically heated pressure, suction and throttle line lengths from 500mm to 3metres.

A key component is the urea quality sensor – it detects and monitors the correct urea liquid composition, enabling an SCR system to function at peak performance. The EcoFit range from Cummins Emissions Solutions offers customers the added convenience and integration benefits of a fully packaged after-treatment system.

718 Liebherr Component Technologies is a new division set up by the German manufacturer to promote the sale and distribution of its components to external customers. Its portfolio includes 16 product lines in 14 business areas including diesel and gas engines, fuel injection systems, drives, axial piston pumps and motors.

For Tier 4 final, the company’s latest generation of engines operate with SCR-only technology, avoiding the need for a particulate filter, oxidation catalyst or exhaust gas recirculation. But the firm offers much more than the latest emissions compliant engine packages – Liebherr Component Technologies also offers basic engine packages with standardised interfaces for Tier 3 compliance. This means a compact EGR system for the Tier 3 version, which can be removed for less regulated markets requiring basic engines. The Liebherr Component Technologies engine portfolio includes four inline engines, a V8 and a V12 configuration with power outputs ranging from 160-750kW.

255 JCB Power Systems is looking to become one of the world’s top three engine suppliers in the construction and industrial sectors in the next 10 years and part of that process means offering an extended line-up of engines beyond its four-cylinder portfolio. Enter the Dieselmax 672 – JCB Power Systems’ new six-cylinder engine platform. Unveiled in the UK towards the end of 2013, the firm introduced the 7.2litre capacity six-cylinder to a US audience to showcase its capabilities.

Launched in mid-2013 as a Tier 2 compliant power unit for less regulated markets, the Dieselmax 672 now gains external exhaust gas recirculation (EGR) to meet Tier 3 emission levels. With specific fuel consumption said to be as low as 189g/kWh, the six-cylinder engine delivers power outputs from 140kW to 212kW. It is anticipated that this latest JCB engine development will soon adopt a similar Tier 4 Final emissions solution to that used on the company’s smaller four-cylinder Ecomax engine range.

The Ecomax engine uses highly efficient combustion technology for the 4.4litre and 4.8litre versions, allowing them to meet the required standards without the use of a diesel particulate filter (DPF). A compact selective catalytic reduction (SCR) solution will be used on engines above 55kW and the SCR catalyst is incorporated into a single exhaust silencer, in most cases replacing the existing exhaust box, to provide a ‘one-can’ solution. It is recognised as a compact solution that remains straightforward to install in a wide variety of machines without incurring costly modifications to bodywork.

Lower down the power sector,6902 Doosan Infracore’s engine business group launched a new range of compact diesel engines that meet Tier 4 Final emissions legislation and also avoid using a diesel particulate filter (DPF). Called the D18, D24 and D34, the three-model range spans an output range from 20-90kW and offers engine capacities of 1.8, 2.4 and 3.4litres as it targets OEM skid steer loader, compact excavator, air compressor and generator businesses.

The non-DPF solution means the two smaller models need only a diesel oxidation catalyst (DOC), while the larger 3.4litre uses DOC with a selective catalytic reduction (SCR) after-treatment system. Engine development was under consultation with FEV Group and1575 Ricardo - both internationally recognised powertrain and vehicle engineering companies – steering Doosan towards an ultra-low particulate combustion (ULPC) engine design that has taken six years to come to fruition. As a result, the compact engine series uses electronic common rail injection, cooled EGR and an optimised piston bowl and combustion chamber. Engine characteristics include a recommended 500hour oil change interval, and Doosan said it expects the engine to offer a fuel consumption of around 2.5litres/hour – 0.4litres lower than the industry average.

FPT Industrial also launched a compact diesel engine called the R22. The three-cylinder power unit covers the 33-52kW sector and combines a diesel oxidation catalyst with a partial-flow filter and cooled exhaust gas recirculation. FPT’s solution uses passive regeneration and is a fully automatic system that needs no intervention from the operator. Expect to the see the R22 series in different states of tune – adjustments are little more than a change of data sets on the engine ECU – being installed in mini excavators, gen-sets and pumps, for example.

Solutions for Tier 4 Final emissions regulations dominated

Deutz’s SCR package uses a combined DOC/SCR catalyst as the first phase of exhaust treatment, followed by a ‘clean-up’ catalyst. While slightly bulkier than a single SCR system, the dual SCR package uses one tank and two dosing systems, but does not use twice as much fluid, said the company. Expect diesel exhaust fluid consumption to increase by 2%, said the company. Despite the increased fluid consumption for after-treatment, the Deutz V6 and V8 engines are said to offer up to 8% more performance with average fuel consumption reduced by around 5% compared to the previous Tier 4 interim versions.

Importantly, the QSG12 brings a major advantage for Tier 4 Final equipment installations by restoring the envelope size of its QSM11 predecessor, which was used for Tier 3 applications. Higher efficiency air handling and advanced combustion enable the QSG12 to return to the simplicity of a wastegated turbocharger and achieve near-zero emissions without the need for a cooled exhaust gas recirculation (EGR) system.

As a result, internal loads on the QSG12 are reduced, said Cummins, to free up extra power potential, while heat rejection is lowered by over 40% compared with engines using cooled EGR.

With Cummins partnering with driveline specialist

The hybrid package is a complete electric driveline system. It starts with the 12litre QSG engine that carries a reluctance-type motor/generator to produce electrical power. This electrical energy is used to drive the wheels through individual high power electric wheel motors.

Oil-cooled 65kW switch reluctance wheel motors contain a single-speed gearbox, creating a 100:1 reduction to transfer electrical power into high torque wheel drive. Each wheel motor’s gearbox contains park and service brakes, and allows regenerative energy recovery under braking – Ideal for repetitive duties performed by wheeled loaders. An ultra-capacitor bank is used to store and release electrical energy on-demand.

While the system is still in the development stages, Cummins engineers expect the QSG engine to operate as a constant speed engine, in a sweet spot of around 1,200rpm while delivering 298kW. The hybrid system is currently being installed in the LW900K - a 30tonne class

Oerlikon expects the hybrid system to be lighter in overall weight to conventional driveline components. Further benefits of such a system, said the company, is that the compact wheel motor design used by the hybrid driveline could eventually lead to the development of independent suspension for wheeled loaders.

With Tier 4 Final in mind, Cummins’ Emissions Solutions division has introduced a range of EcoFit urea tanks and lines for those adopting SCR after-treatment systems. EcoFit includes four tank capacities – 19, 38, 57 and 114litres – including two different shape profiles for additional installation flexibility. The portfolio also includes electrically heated pressure, suction and throttle line lengths from 500mm to 3metres.

A key component is the urea quality sensor – it detects and monitors the correct urea liquid composition, enabling an SCR system to function at peak performance. The EcoFit range from Cummins Emissions Solutions offers customers the added convenience and integration benefits of a fully packaged after-treatment system.

For Tier 4 final, the company’s latest generation of engines operate with SCR-only technology, avoiding the need for a particulate filter, oxidation catalyst or exhaust gas recirculation. But the firm offers much more than the latest emissions compliant engine packages – Liebherr Component Technologies also offers basic engine packages with standardised interfaces for Tier 3 compliance. This means a compact EGR system for the Tier 3 version, which can be removed for less regulated markets requiring basic engines. The Liebherr Component Technologies engine portfolio includes four inline engines, a V8 and a V12 configuration with power outputs ranging from 160-750kW.

Launched in mid-2013 as a Tier 2 compliant power unit for less regulated markets, the Dieselmax 672 now gains external exhaust gas recirculation (EGR) to meet Tier 3 emission levels. With specific fuel consumption said to be as low as 189g/kWh, the six-cylinder engine delivers power outputs from 140kW to 212kW. It is anticipated that this latest JCB engine development will soon adopt a similar Tier 4 Final emissions solution to that used on the company’s smaller four-cylinder Ecomax engine range.

The Ecomax engine uses highly efficient combustion technology for the 4.4litre and 4.8litre versions, allowing them to meet the required standards without the use of a diesel particulate filter (DPF). A compact selective catalytic reduction (SCR) solution will be used on engines above 55kW and the SCR catalyst is incorporated into a single exhaust silencer, in most cases replacing the existing exhaust box, to provide a ‘one-can’ solution. It is recognised as a compact solution that remains straightforward to install in a wide variety of machines without incurring costly modifications to bodywork.

Lower down the power sector,

The non-DPF solution means the two smaller models need only a diesel oxidation catalyst (DOC), while the larger 3.4litre uses DOC with a selective catalytic reduction (SCR) after-treatment system. Engine development was under consultation with FEV Group and

FPT Industrial also launched a compact diesel engine called the R22. The three-cylinder power unit covers the 33-52kW sector and combines a diesel oxidation catalyst with a partial-flow filter and cooled exhaust gas recirculation. FPT’s solution uses passive regeneration and is a fully automatic system that needs no intervention from the operator. Expect to the see the R22 series in different states of tune – adjustments are little more than a change of data sets on the engine ECU – being installed in mini excavators, gen-sets and pumps, for example.