A combination of engine and driveline technologies will reduce fuel consumption and increase performance in new generation, low emission machines

A wide array of new engine and driveline technologies being developed will help reduce emissions and fuel consumption, while increasing performance in the

latest machines coming to market. With engine manufacturers focussing on the Tier 4 Interim/ Stage IIIB and following Tier 4 Final/Stage IV emissions requirements for North America and Europe, sophisticated

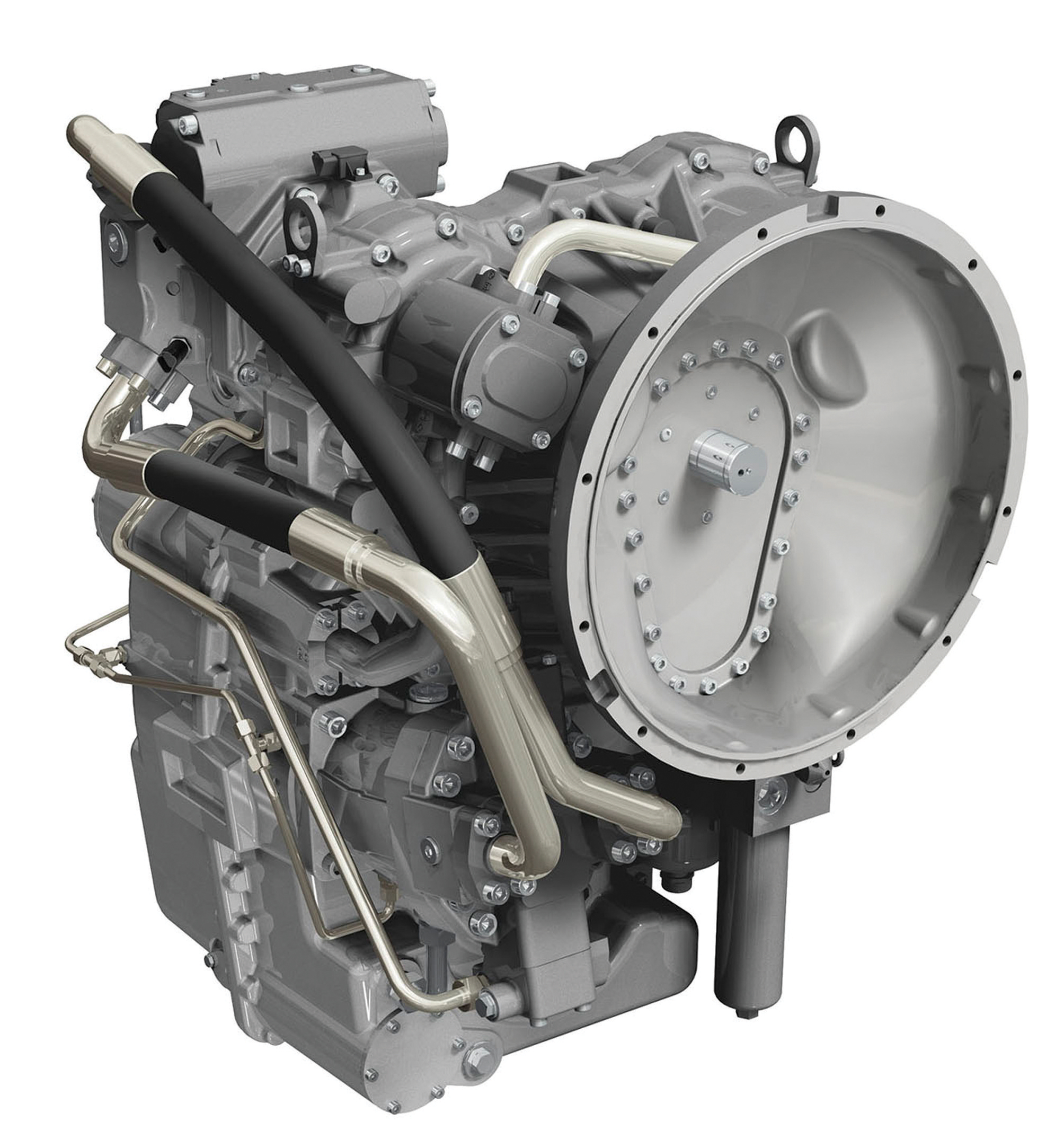

The latest driveline technology helps maximise efficiency

A combination of engine and driveline technologies will reduce fuel consumption and increase performance in new generation, low emission machines

A wide array of new engine and driveline technologies being developed will help reduce emissions and fuel consumption, while increasing performance in the latest machines coming to market. With engine manufacturers focussing on the Tier 4 Interim/ Stage IIIB and following Tier 4 Final/Stage IV emissions requirements for North America and Europe, sophisticated technologies are being offered by all the major suppliers. Meanwhile driveline improvements will also play a key role in ensuring the new generation machines meet emissions targets, while also offering performance improvements.

To achieve the emissions reduction targets, different technologies are being used by the various engine suppliers. Full information had not been made available on the latest developments from some leading firms at the time of writing. However, a number of major engine manufacturers have released information on how their new generation engines would address the emissions challenge.

From

Meanwhile

The new engine ratings allow customers to down-size. They will be able to replace a large-displacement Tier 3 engine with a smaller engine that delivers a higher power density. This also compensates for the additional cost for cooling and emissions control systems. The D-Vert system is modular and this offers an important benefit as it means the engine can have the emissions package removed if necessary. This will allow exports of secondhand equipment to markets that do not need to meet such legislation.

Research and development has shown that an application-specific SCR system that is well integrated with John Deere’s proven Interim Tier 4/Stage III B engine platform provides an effective solution to achieve Final T er 4/Stage I emissions compliance while delivering power, performance, ease of operation, fluid efficiency, reliability and economical operating costs.

Consisting of an exhaust filter and SCR after-treatment components that are optimised and fully integrated, the new Integrated Emissions Control system will allow John Deere engines to consume less diesel exhaust fluid (DEF) than alternative Interim Tier 4 SCR technology solutions, according to the firm. Lower DEF consumption means that the tank size can be smaller, making installation into existing chassis easier, extending DEF filter service intervals and reducing operator involvement.

John Deere’s Final Tier 4/Stage IV technology solution is said to optimise performance and efficiency, which takes into account total fluid consumption including diesel fuel and additional fluids such as diesel exhaust fluid (DEF). These engines will run with conventional low-sulphur diesel as well as 5-20% biodiesel (B5-B20) blends that meet applicable ASTM standards, providing performance and fuel choice flexibility.

As John Deere designs engines for OEM applications and its own construction machines the firm has expertise in integrating the engine with the drivetrain, hydraulics, electronic control unit (ECU), cooling package and other vehicle systems.

The four-cylinder engines represent a new sector for the firm and the 3.4litre has a high power density, delivering 100kW. Previously, the firm’s engine range stopped at a 2.2litre diesel delivering 60kW.

The company claims that customers will be able to downsize from larger engines built by other firms to the new 3.4litre turbo diesel and still have the required power. Using common rail injection pressures up to 2,000bar, EGR, electronic engine management and turbocharging, the KDI series has the potential to deliver lower operating costs from higher efficiency and longer servicing intervals.

Fuel consumption is reduced by 15% according to Lombardini, although the complexity of this latest technology is likely to see these new engines costing up to 20% more than their predecessors.

Scania’s integration of XPi high pressure common rail injection and selective catalytic reduction has enabled the Swedish engine maker to meet 2014 Stage IV/Tier 4 Final emissions regulations without a diesel particulate filter. Developments in metallurgy have helped to strengthen components and lead to increased injection pressures, typically up to 2400bar. A compact DOC is integrated into the SCR system, which saves on space needed for OEMs with installation constraints. The modular development programme for the inline five- and six-cylinder platforms, plus the 16litre V8 engine, has enabled refinement of combustion and cooled EGR processes. The company has a lot of experience with this technology, having developed it initially for its on-road applications. The firm says that it may need to add an exhaust brake on engines operating under light duty cycles to raise the exhaust temperature so that SCR remains effective at very light loads however.

Yanmar Europe is offering a new series of water-cooled industrial diesel engines that meet the new Tier 4 and EU Stage IIIB off-highway emission regulations up to 56kW. Based on its TNV series, the new range includes 10 models in three- and four-cylinder formats with indirect and direct injection, and ranging from 10kW - 56kW. Engines over 19kW use an ECU-controlled common rail fuel injection, cooled EGR, a new throttle valve and a diesel particulate filter (DPF). A new diagnostic system called Yanmar SA-D, and the remote monitoring system

JCB has managed to steer clear of additives for its Stage IIIB/Tier 4 Interim engines solutions. What’s more, the UK manufacturer claims that it will be able to achieve Stage IV/ Tier 4 Final with its Ecomax engines without resorting to an after-treatment additive.

Bell Equipment says it is one of the world’s first articulated dump truck (ADT) manufacturers to offer EU Stage IIIB/Tier4 Interim compliance across its entire range. Using SCR technology, the company says that tests run at its South African manufacturing facility show significant fuel savings on the new SCR Stage IIIB trucks versus the previous Bell Stage 3/Tier 3 engine trucks.

Managing director of

“The complete design package of the Stage IIIB Bell ADTs enhances the fuel savings due to both the design of the Mercedes Benz SCR engine and because Bell ADTs are designed to be weight optimised.”

Bell Stage IIIB ADTs do not produce large amounts of PM, but do produce NOx gases, and to deal with this it is utilising the

“We are excited by the fuel efficiency test results because a possible 15% fuel saving will have a significant impact to the bottom line of our customers. Fuel is a large portion of the owning and operating cost of any earthmoving machinery with an estimated 40% of the owning and operating costs being allocated to fuel.

“Importantly it means that Bell Blu@ dvantage will not only reduce the carbon footprint of our machines, but also achieve a possible 20% fuel advantage,” added Schürmann.

The company is also launching Bell Lubricants, a new range of oils, fluids and greases that will be distributed to and sold by Bell dealerships throughout Europe.

However, it is worth noting that to capitalise on the new engine technologies being used, sophisticated drivelines are also being developed. These feature electronics that tie into the ECU of the engine, for greater overall efficiency. And continuously variable transmissions are now making their entry into the construction equipment market, having been developed initially for the automotive sector and having since been proven in industries such as agriculture.

Meanwhile Dana Rexroth’s HVT R3 is a hydro-mechanical variable transmission for wheeled loaders with engine outputs of up to 265kW and is the first power split transmission from the joint venture between

Using a combination of hydrostatic and mechanical drives, the technologically advanced three-range transmission can offer up a fuel saving of up to 20% by delivering a stepless speed range from 0-40km/hr without clutches and without interrupting the drive.

The HVT R3 allows an operator to preset a maximum travel speed, or preselect a fixed engine rpm and use the transmission’s characteristics to keep the engine working at its most fuel-efficient point.

ZF’s cPower transmission is a CVT gearbox (Continuously Variable Transmission) suited to wheeled loader use, eliminating the need for a torque converter. The system has been developed using the firm’s experience from the agricultural tractor sector, where CVT gearboxes have been in use for over 10 years, the cPower transmission uses a blend of hydrostatics and mechanical drives to split power throughout the entire working speed range with the aim of managing and reducing engine revs independently to travel speed.

Cleverly, cPower will automatically adjust engine speed and use only the power it needs to reach and maintain a chosen travel speed. The result can be up to 30% less fuel consumption and up to 20% more operating efficiency as the transmission seamlessly manages travel speeds without any interruption in drive.