The diesel engine manufacturers are continuing their development of low emission engines as well as solutions for markets where fuel quality is an issue - Mike Woof writes. Developments in diesel engine technology are the continued focus for manufacturers facing tough challenges around the world. New low emission engines are being developed for developed markets such as Europe and the US, with Europe now taking a further step ahead to target pollutants from the tailpipe. Meanwhile firms are also looking int

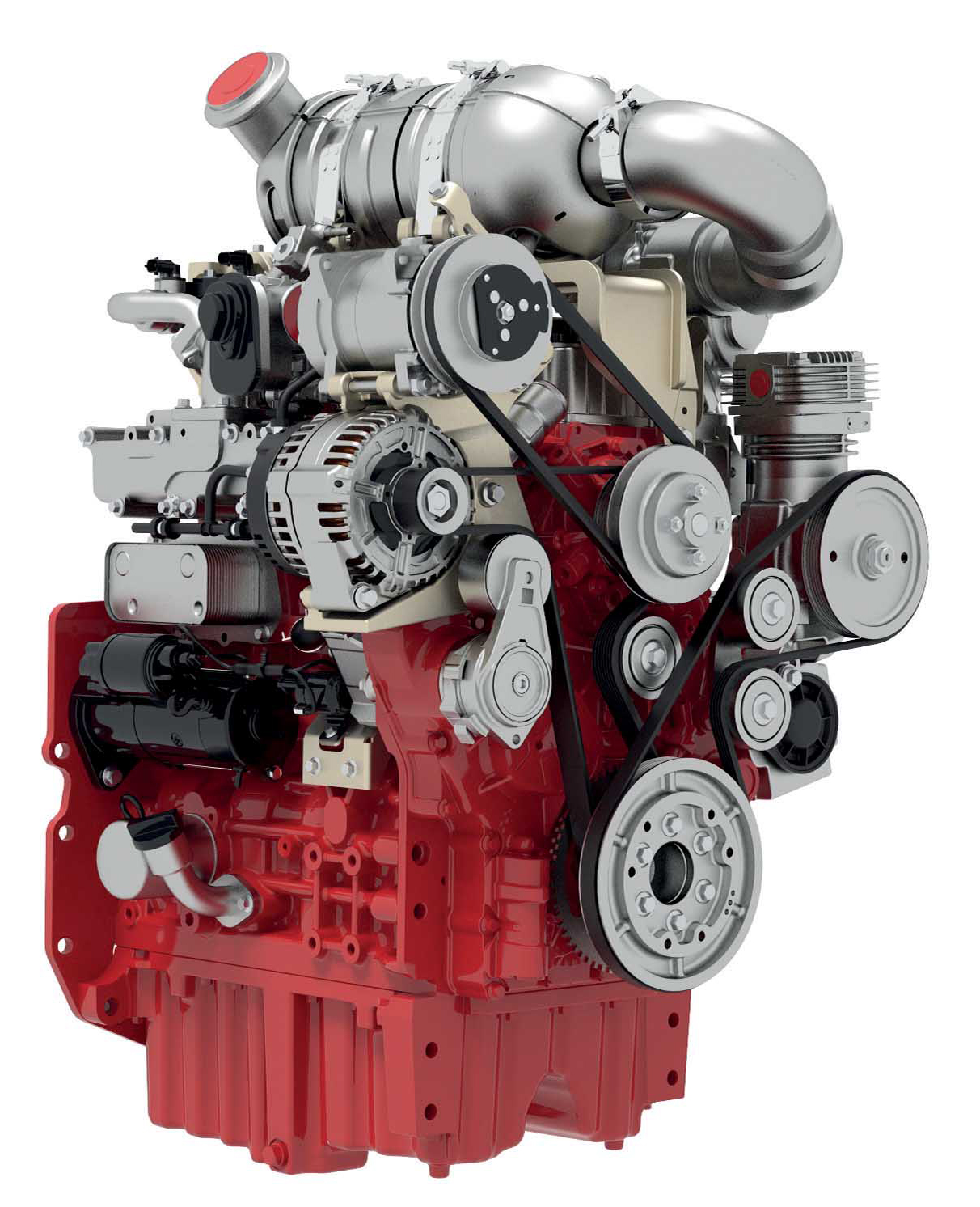

A version of the DEUTZ TCD3.6 engine has been developed that will run on natural gas without a drop in power output

The diesel engine manufacturers are continuing their development of low emission engines as well as solutions for markets where fuel quality is an issue - Mike Woof writes

Developments in diesel engine technology are the continued focus for manufacturers facing tough challenges around the world. New low emission engines are being developed for developed markets such as Europe and the US, with Europe now taking a further step ahead to target pollutants from the tailpipe. Meanwhile firms are also looking into solutions for engines sold in markets where low quality fuels mean that the new generation, low emission engines cannot be used.

Europe’s plan for a Stage V level of emissions requirements for diesels takes it beyond the outline agreed with the US. The EU Stage V emissions legislation due to come into force in 2019 will require a reduction not only in soot particulate mass but also number. This has pushed manufacturers to develop new concepts to reduce emissions, particularly of particulates. German firm201 DEUTZ is one of the first to announce its solutions for this emissions requirement and now says that it has engines ready for EU Stage V.

The firm has EU Stage V-ready engines in the 2.9-7.8litre capacity range and says that its customers will benefit from using proven DPF technology. The standard is based on the EU Commission's Stage V proposal of 25th September 2014 and is expected to be implemented with effect from January 2019. However DEUTZ says that it is able to meet this standard by fitting diesel particulate filters (DPF) which are already successfully in use in series production engines. These engines can be identified by their Stage V ready seal.

Michael Wellenzohn, a member of the board of management of DEUTZ with responsibility for sales/service & marketing explained, "Our Stage V-ready engines allow us to provide our customers with the best possible support in their transition to Stage V products. We will achieve this thanks to the experience we have already gained in exhaust gas aftertreatment, especially in the use of diesel particulate filters."

There will also be emission downgrade engines, making it possible to use an across-the-board engine platform both in Stage V markets and in areas with more relaxed regulations.

The company has also been developing a version of its TCD3.6 engine in partnership with Rostock University that can be run on methane gas, without any loss of performance. The aim of this project is to offer reduce the emissions of pollutants as well as CO2 and the research project has also been supported by the German Federal Environmental Foundation (DBU).

257 John Deere Power Systems (JDPS) is now offering a new unit for use in generator applications. The 3089 PowerTech PSL 13.5L is the most powerful in the range of engines meeting the Tier 4 Final requirements without the need for a diesel particulate filter (DPF).

This allows OEMs more installation options for generator set applications. As with the other engines without DPFs in the generator line-up, this new 13.5L engine features a John Deere Integrated Emissions Control system with cooled exhaust gas recirculation (CEGR), a diesel oxidation catalyst (DOC) and a selective catalytic reduction (SCR) system.

The new PowerTech PSL 13.5L generator drive engine is rated at 473kWm and, in addition to generator sets, can be used to provide power to select constant speed applications. Features include low idle speeds, dual frequency ratings and easy paralleling.

The new PowerTech PSL 13.5L generator drive engine model means that there will be six models in the line-up. John Deere plans to begin production of the PowerTech PVL and PSL 6.8L generator drive engine in late 2015 while the PowerTech PSL 4.5L, 9.0L and 13.5L generator drive engines will enter production in early 2016.

John Deere offers an extensive range of standby and prime generator set engines that meet emissions regulations while delivering quick-starting, clean-running and fuel-efficient performance. The full extent of John Deere generator drive engines ranges in displacement from 2.9L to 13.5L and covers generator drive ratings from 31 to 563 kWm. These engines include non-emissions certified, Tier 2, Tier 3, Tier 4 Interim and Tier 4 Final models.

2300 Komatsu Europe meanwhile is now offering an engine solution that will enable its Stage IIIB emissions certified engines to be used in markets where high-quality, ultra low sulphur diesel (ULSD) fuel is not available. This Komatsu-approved modification process will be carried out by authorised Komatsu dealers and will help ensure resale values for the machines.

Jim Venerus, Komatsu Europe Product Marketing DGM said, “Certain EU Stage IIIB engine technologies may not operate at peak performance levels in lesser regulated territories where non-ULSD fuel is used. The Komatsu-approved conversion process allows Komatsu dealers to provide a quick and easy solution to our customers without compromising product performance.”

The conversion process is permanent and means that converted machinery cannot then be used in regulated markets.

Looking to the future for the engine sector, Rolls-Royce subsidiary7648 MTU is to continue to cooperate with 3992 Daimler on developing and building high-speed MTU diesels for use in construction equipment. Taking the Daimler OM 93x and OM 47x commercial vehicle engines as a basis, MTU and Daimler will jointly develop MTU Series 1000, 1100, 1300 and 1500 units that comply with the European Stage V off-highway emissions standard. These engines deliver 100-480kW and are to be available ahead of the launching of the new EU Stage V emissions standard scheduled for 2019. MTU engines will meet the more stringent emissions limits with the use of an additional diesel particulate filter. Further in-engine innovations will also help lower fuel consumption.

The two companies also agreed to extend their supply contracts for industrial engines compliant with older emissions stages. “Industrial engines account for a significant share of our business that we will continue to grow,” said Dr Ulrich Dohle, CEO of Rolls-Royce Power Systems. “By extending our existing supply contracts, we are making industrial engines for all relevant emissions stages available to our customers on a long-term basis. At the same time, we can already unveil our solution for the new EU Stage V legislation.”

A number of engine companies are also preparing themselves for engine emissions requirements of other markets.299 Perkins says that its 1104 and 1106 mechanical and electronic engines are now ready to meet the China Nonroad Stage III emissions standards, which are similar (but not identical) to those of the European Stage IIIA and US Tier 3 standards.

“We offer OEMs a comprehensive range of mechanical and electronic engines that meet China Nonroad Stage III,” said 1100 Series product marketing manager Leighton Morgan. “As a full range engine supplier, our ability to offer both mechanical and electronic solutions to meet China Nonroad Stage III is attracting a lot of interest from Chinese OEMs, many of who are looking to continue manufacturing mechanically powered machines, in addition to introducing new electronic models.”

For construction machine manufacturers the new Perkins mechanical engines offer a simple and fast upgrade to China Nonroad Stage III emissions standards. The 1106D-70TA is designed with construction machines in mind, with performance optimised for 20-25tonne hydraulic excavators and 3-4tonne wheeled loaders.

The mechanical 1106 shares a common platform with the electronically controlled 7litre model, capable of producing up to 205kW at 2,200rpm with a maximum torque of 1050Nm at 1,400rpm, while the 1104 electronic offers up to 106kW at 2,200 rpm and maximum torque of 556Nm at 1,400rpm.

The higher power densities and torque levels of the Perkins six-cylinder electronic engine are said to offer further benefits for users. OEMs would typically use a 10litre engine to power a 5tonne wheeled loader, but the latest electronic, six-cylinder, 7litre engine from Perkins can carry out the job of a larger displacement engine, while its compact size means better heat dissipation, making it more efficient and far more competitive on a whole-life cost basis.

Certifying mechanical engines for China Nonroad Stage III emissions standards has proven to be challenging. But Perkins engines have now completed the stringent testing requirements. "Perkins' ability to offer mechanical and electronic 4.4 and 7 litre engines to meet China Stage III gives Chinese OEMs greater choice and flexibility,” stated Leighton.

Developments in diesel engine technology are the continued focus for manufacturers facing tough challenges around the world. New low emission engines are being developed for developed markets such as Europe and the US, with Europe now taking a further step ahead to target pollutants from the tailpipe. Meanwhile firms are also looking into solutions for engines sold in markets where low quality fuels mean that the new generation, low emission engines cannot be used.

Europe’s plan for a Stage V level of emissions requirements for diesels takes it beyond the outline agreed with the US. The EU Stage V emissions legislation due to come into force in 2019 will require a reduction not only in soot particulate mass but also number. This has pushed manufacturers to develop new concepts to reduce emissions, particularly of particulates. German firm

The firm has EU Stage V-ready engines in the 2.9-7.8litre capacity range and says that its customers will benefit from using proven DPF technology. The standard is based on the EU Commission's Stage V proposal of 25th September 2014 and is expected to be implemented with effect from January 2019. However DEUTZ says that it is able to meet this standard by fitting diesel particulate filters (DPF) which are already successfully in use in series production engines. These engines can be identified by their Stage V ready seal.

Michael Wellenzohn, a member of the board of management of DEUTZ with responsibility for sales/service & marketing explained, "Our Stage V-ready engines allow us to provide our customers with the best possible support in their transition to Stage V products. We will achieve this thanks to the experience we have already gained in exhaust gas aftertreatment, especially in the use of diesel particulate filters."

There will also be emission downgrade engines, making it possible to use an across-the-board engine platform both in Stage V markets and in areas with more relaxed regulations.

The company has also been developing a version of its TCD3.6 engine in partnership with Rostock University that can be run on methane gas, without any loss of performance. The aim of this project is to offer reduce the emissions of pollutants as well as CO2 and the research project has also been supported by the German Federal Environmental Foundation (DBU).

This allows OEMs more installation options for generator set applications. As with the other engines without DPFs in the generator line-up, this new 13.5L engine features a John Deere Integrated Emissions Control system with cooled exhaust gas recirculation (CEGR), a diesel oxidation catalyst (DOC) and a selective catalytic reduction (SCR) system.

The new PowerTech PSL 13.5L generator drive engine is rated at 473kWm and, in addition to generator sets, can be used to provide power to select constant speed applications. Features include low idle speeds, dual frequency ratings and easy paralleling.

The new PowerTech PSL 13.5L generator drive engine model means that there will be six models in the line-up. John Deere plans to begin production of the PowerTech PVL and PSL 6.8L generator drive engine in late 2015 while the PowerTech PSL 4.5L, 9.0L and 13.5L generator drive engines will enter production in early 2016.

John Deere offers an extensive range of standby and prime generator set engines that meet emissions regulations while delivering quick-starting, clean-running and fuel-efficient performance. The full extent of John Deere generator drive engines ranges in displacement from 2.9L to 13.5L and covers generator drive ratings from 31 to 563 kWm. These engines include non-emissions certified, Tier 2, Tier 3, Tier 4 Interim and Tier 4 Final models.

Jim Venerus, Komatsu Europe Product Marketing DGM said, “Certain EU Stage IIIB engine technologies may not operate at peak performance levels in lesser regulated territories where non-ULSD fuel is used. The Komatsu-approved conversion process allows Komatsu dealers to provide a quick and easy solution to our customers without compromising product performance.”

The conversion process is permanent and means that converted machinery cannot then be used in regulated markets.

Looking to the future for the engine sector, Rolls-Royce subsidiary

The two companies also agreed to extend their supply contracts for industrial engines compliant with older emissions stages. “Industrial engines account for a significant share of our business that we will continue to grow,” said Dr Ulrich Dohle, CEO of Rolls-Royce Power Systems. “By extending our existing supply contracts, we are making industrial engines for all relevant emissions stages available to our customers on a long-term basis. At the same time, we can already unveil our solution for the new EU Stage V legislation.”

A number of engine companies are also preparing themselves for engine emissions requirements of other markets.

“We offer OEMs a comprehensive range of mechanical and electronic engines that meet China Nonroad Stage III,” said 1100 Series product marketing manager Leighton Morgan. “As a full range engine supplier, our ability to offer both mechanical and electronic solutions to meet China Nonroad Stage III is attracting a lot of interest from Chinese OEMs, many of who are looking to continue manufacturing mechanically powered machines, in addition to introducing new electronic models.”

For construction machine manufacturers the new Perkins mechanical engines offer a simple and fast upgrade to China Nonroad Stage III emissions standards. The 1106D-70TA is designed with construction machines in mind, with performance optimised for 20-25tonne hydraulic excavators and 3-4tonne wheeled loaders.

The mechanical 1106 shares a common platform with the electronically controlled 7litre model, capable of producing up to 205kW at 2,200rpm with a maximum torque of 1050Nm at 1,400rpm, while the 1104 electronic offers up to 106kW at 2,200 rpm and maximum torque of 556Nm at 1,400rpm.

The higher power densities and torque levels of the Perkins six-cylinder electronic engine are said to offer further benefits for users. OEMs would typically use a 10litre engine to power a 5tonne wheeled loader, but the latest electronic, six-cylinder, 7litre engine from Perkins can carry out the job of a larger displacement engine, while its compact size means better heat dissipation, making it more efficient and far more competitive on a whole-life cost basis.

Certifying mechanical engines for China Nonroad Stage III emissions standards has proven to be challenging. But Perkins engines have now completed the stringent testing requirements. "Perkins' ability to offer mechanical and electronic 4.4 and 7 litre engines to meet China Stage III gives Chinese OEMs greater choice and flexibility,” stated Leighton.