The forthcoming Tier 4 emissions legislation represents a great leap forward in technology, Mike Woof reports

A high-profile focus on sustainability and reduced environmental impact is sweeping the construction sector in the European Union (EU) and the US. The EU and the US will implement regulations for the lowest emission off-road machines in history, with Canada and Japan expected to release similar regulatory programmes this year.

The legislation being introduced will transform the construction indu

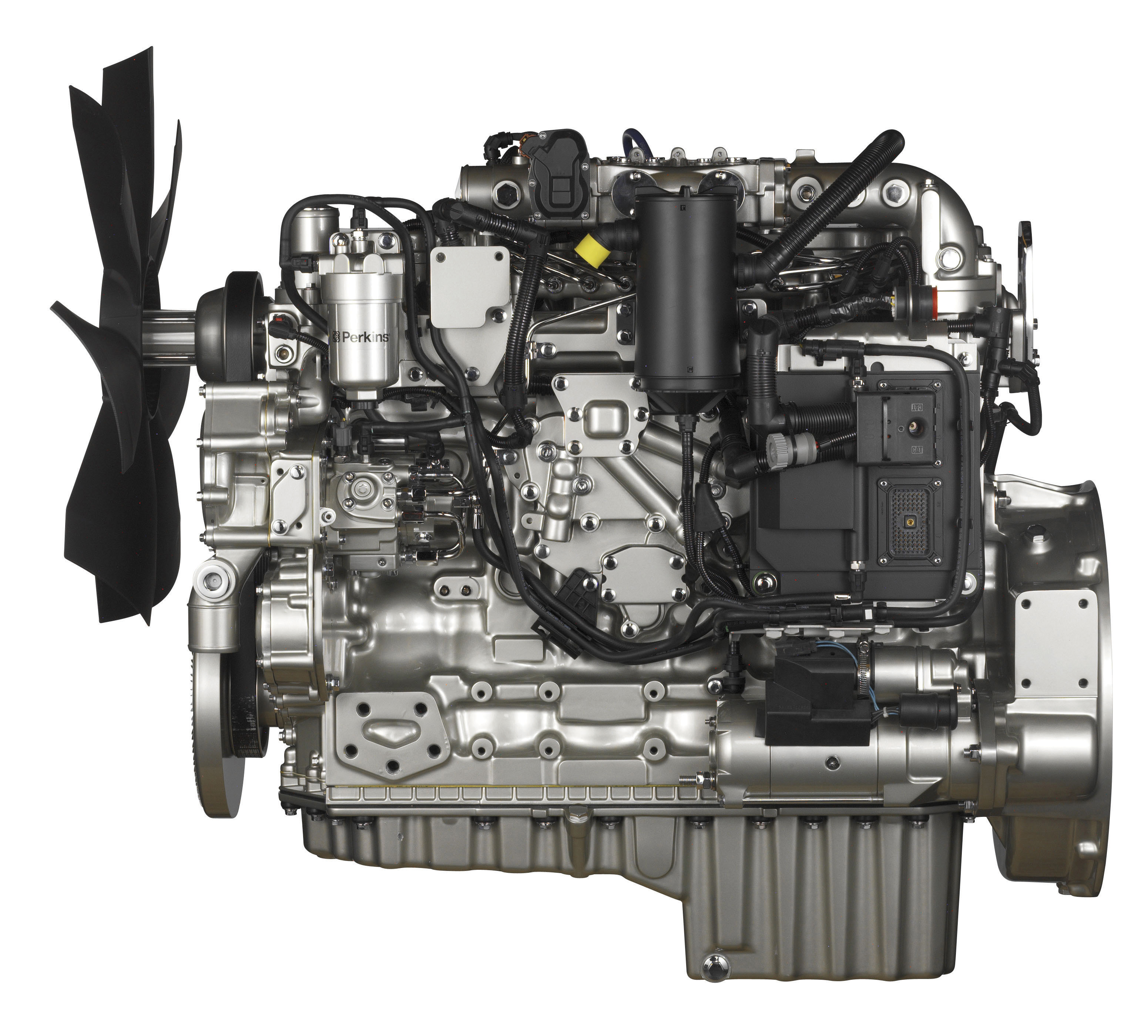

As part of the Caterpillar Group, Perkins has had access to its parent's emissions technology for its new engine range

The forthcoming Tier 4 emissions legislation represents a great leap forward in technology, Mike Woof reports

A high-profile focus on sustainability and reduced environmental impact is sweeping the construction sector in theThe legislation being introduced will transform the construction industry, with machines that are cleaner and more efficient in operation due to massive technological developments in engines as well as drivelines. The

For construction equipment manufacturers this has fuelled a massive investment in research and development to meet the tough programme. And to ensure customers see the full benefit of these new diesels, manufacturers have also been focussing on improving engine output and response curves, reducing fuel consumption, extending service intervals and lowering the overall running costs of each machine. Because of the substantial technical challenges posed by this transition phase, the US

However, as part of the Transition Programme for Equipment Manufacturers (TPEM, also knows as the flex programme), the EPA is allowing equipment manufacturers to continue to introduce machines powered with engines meeting previous Tier emission requirements. This will be permitted for a certain limited percentage of the overall production volumes during the Tier 4 timeframe and the EU has a similar transition schedule. The EU also has a sell off programme that allows manufacturers to continue selling previous Tier machines as part of the ramp up to the new emission regulations. These transitional schedules have been calculated into the environmental improvements set by the regulators during development of the schedules.

And crucial to the introduction of the Tier 4 interim/Stage IIIB and Tier 4 final/Stage IV technologies will be the availability of clean diesel fuel with ultra-low levels of sulphur. This is an important point as high sulphur fuels can cause rapid wear and extensive damage to emission compliant engines, drastically reducing an expected operating life of say 15,000hours to just a few hundred hours.

As a leading player in the construction equipment sector,

He said, "A few years ago the question was, 'Is the diesel engine the powerplant for the future?'

However the success of current technologies for reducing emissions and noise has shown that diesels do have a future. He said, "Tier 1 was pretty easy, there was a big jump to get to Tier 2 but when we came to Tier 3, that was a biggie."

The firm spent around US$1 billion to develop its ACERT technology for the Tier 3 regulations and is continuing to invest in systems that will help deliver a 90% reduction in NOx and particulate emissions for Tier 4. Parker said, "If you look at last year we spent $6 million/day in research and development, most of which was for Tier 4."

Caterpillar says it has carried out the most aggressive product development programme in its history so as to be able to beat customer expectations for Tier 4. The firm is now offering its C13, C15, C18, C27 and C32 with ACERT technology that will meet the Tier 4 interim/Stage IIIB legislation, with power outputs from 287-895kW. Putting the cost of the investment into perspective, the Tier 3 changes had to be made to 150 models in the Caterpillar range while the Tier 4 upgrades will be rolled out across 300 models. And as the Tier 4 emissions programme is being introduced in two phases Parker added, "Many of these products will have to be changed twice."

Clearly Caterpillar cannot be expected to invest in this technology without some form of recompense. Parker said, "We're going to spread that increase across a range of products. We can't afford a smaller product to jump in price and a larger product to stay about the same."

Tana Utley is chief technology officer at Caterpillar and is in charge of the firm's technology centre in Peoria, where much of the Tier 4 development is taking place. She said, "Technology does not create customer value. It's how you apply that technology."

The new emissions package is complex and to reduce on future installation costs Caterpillar has ensured that the Tier 4 interim and final installations use the same basic layout. The key difference will be with the diesel oxidation filter and diesel particulate filter for Tier 4 final. Utley said, "This is a significant package to install and we've designed it so that if we decide to introduce after-treatment, we can and make it as compact as we can get it."

The modules come in a small number of basic installations to suit the many models in the Caterpillar range and the firm talked with many product specialists to ensure these modular units would be suitable. These are also tailored so that Caterpillar's engine customers can fit the packages to their machines.

Caterpillar has still to decide on its Tier 4 final specification though. Utley said that the firm does have a selective catalytic reduction (SCR) system available for use on the Tier final engines, "But we haven't made that decision yet."

Extensive testing has been carried out under an array of simulated load conditions in test cells. Data on loads exerted on engines, drivetrains and hydraulics taken from machines operating in the field has been recorded, loaded into a computer and used to model simulations of working conditions for the test cell. Utley said, "We fooled the powertrain to think it was in the dirt."

A shaking table is used to test machine structures and ensure that components such as the new emissions modules will withstand tough site conditions. And a new covered facility allows Caterpillar to carry out machine testing under carefully controlled conditions and these are run all year round, without having to worry about the weather. At the same time the firm has carried out an extensive testing programme of machines in the field with several customers. It is expected that Caterpillar will clock around one million hours of testing on Tier 4 Interim/Stage IIIB engines and machines by the end of 2010.

Caterpillar's Tier 4 interim/Stage IIIB engine package is based on a state-of-the-art integrated system developed from the company's ACERT technology. Additional technologies, including power-train advances and after-treatment units, will be specifically tailored for customers while meeting the stringent emission requirements required. Investing in the interim technology as soon as it is commercially available could bring benefits to customers. "Utley said, "If you buy a Tier 4 interim machine you will not be required to upgrade that to Tier 4 final."

The firm's pricing strategy will allow the Caterpillar to recover the costs of meeting the new regulations. For machines in the 130-560 kilowatt power range prices may increase by 12% over the Tier 4 Interim/Stage IIIB introduction time frame.

However, customers will see benefits from using these engines and not just because they meet regulations that will be necessary. Much of the testing is ensuring that the new diesels are more responsive while using less fuel than before. Parker also said that the firm intends to reduce the owning and operating costs of its equipment over the life of the machines.

Biofuels do present an issue for the equipment sector. Utley said, "We can use up to B20 biofuel but we would like to see more regulation on biofuel as we see a lot of difference in quality."

Other equipment firms are well in hand with their plans also.

These four engines come with after-treatment systems to suit off-highway installations. The QSB3.3 and QSB4.5 engines are aimed at the 56-119kW power output range and have the same external dimensions to the existing Tier 3 units, while the new QSX engines offer power outputs from 224-447kW.

A comprehensive field-testing programme has been carried out to ensure that these new engines will meet requirements.

The latest diesel TCD20XX diesel from

The most powerful variants come with two turbochargers, one small and one larger, to provide improved response and high torque at low engine speeds. Both of the 1206 models use a diesel oxidation catalyst (DOC) as well as a diesel particulate filter (DPF) to ensure emissions regulations compliance.

The fuel injection system, developed with Cummins, operates at pressures of up to 2,400bar, providing high torque outputs at low revs and increased output. Engines will be available in 9.3litre five cylinder, 12.7litre six cylinder and 16.4litre V8 variants.

Alan Tolley, JCB's director of engine programmes, said:

"The expectation for the first part of Tier 4 interim/Stage 3B legislation was that to achieve really low particulate levels you needed to fit a Diesel Particulate Filter (DPF).

"Our strategy has been to meet Tier 4 interim emission standards without a DPF but also to achieve this without any exhaust after-treatment. We have focussed our research and development efforts on a high efficiency combustion system: in other words we have made sure we don't create the pollutants to start with rather than try and deal with them later. This approach also gives us very low fuel consumption levels." JCB Power Systems worked closely with research and development specialist Ricardo, using computational fluid dynamics, finite element analysis and a Ricardo-designed combustion bowl to perfect the combustion process.

With second generation common rail fuel injection technology, injection pressures have been raised to 2,000 bar and nozzle hole geometry has been refined to provide highly effective atomisation and distribution of the fuel within the cylinder. JCB has incorporated variable geometry turbochargers on all but the lowest powered 55kW Dieselmax engine, which falls under a slightly different emission regulation. Cooled EGR is also used to clean up the exhaust gases before they are passed from the engine. This means that there is no requirement for any exhaust after-treatment components to meet these emissions levels on the 4.4 litre JCB Ecomax T4 engine.

The company has worked with fuel system and electronics specialist

Under test conditions, the engines have been achieving a 5-10% fuel consumption improvement compared to the previous generation.