Advances in asphalt plant design offer major gains in product throughput and quality, while also allowing for warm asphalt and increased recycling

The asphalt sector is constantly looking for ways to optimise production, lower costs and improve product quality and consistency. Competition is fierce in the asphalt plant market, with several of the key companies working hard to develop new and more efficient technologies, as well as equipment that is more versatile and more mobile. Advances have been made

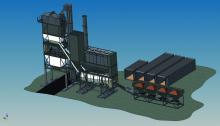

The plant Benninghoven constructed for BAM has been fine-tuned since it was commissioned to further optimise output

Advances in asphalt plant design offer major gains in product throughput and quality, while also allowing for warm asphalt and increased recycling

The asphalt sector is constantly looking for ways to optimise production, lower costs and improve product quality and consistency. Competition is fierce in the asphalt plant market, with several of the key companies working hard to develop new and more efficient technologies, as well as equipment that is more versatile and more mobile. Advances have been made with regard to the use of recycled asphalt as well as the production of warm asphalt types. And both warm asphalt and the use of recycled asphalt pavement (RAP) offer benefits with regard to improving sustainability and reducing asphalt production costs.

There are numerous advantages to be gained from the use of RAP in asphalt production, with plant manufacturers in China, Europe, Turkey and the US all now offering innovative solutions. Demand for such equipment has been fuelled by a need to lower production costs as well as to reduce the environmental impact of road construction. And given that RAP contains valuable bitumen and road aggregates that can be reused economically, it is simply good common sense to use this material rather than wasting it.

Many asphalt plants configured to mix RAP into the production process achieve this with the use of parallel drum systems for recycling and this proven technology has been employed by various manufacturers for some time. However, there are shortcomings with conventional parallel flow drum systems, such as high exhaust gas temperatures and high emission levels. With this in mind, German asphalt plant manufacturer167 Benninghoven has been working with Bavarian Asphalt Plant Works (BAM) to find a different solution for this technology.

The technique of indirectly heating RAP was developed some years ago but took some years to perfect, with different companies working on a range of solutions. For Benninghoven’s team of development engineers, the biggest challenge was to configure the fan system to ensure effective recirculation and efficient exhaust flow, based on theoretical values. Out of this research, key values were estimated. Using the calculated theoretical values, a system could then be configured while a number of additional features were taken into consideration.

A real challenge to the development engineers was how best to minimise fine particles in the exhaust gas. A simple solution was found, allowing the exhaust gases to first pass through a large expansion chamber where the air speed could be reduced. This stage ensures that the particles fall into a collection hopper and can then be transferred by a screw conveyor back into the hot recycling buffer silo.

When testing commenced, the development engineers from BAM and Benninghoven were encouraged to find that the estimated values for improved emissions performance were actually exceeded. During the testing phase the system was closely monitored, emission tests were taken and samples were analysed. Different mixes were used and modified accordingly, and the processes further optimised with the result that the plant was able to perform exactly as originally planned.

The production tests show that the plant delivers a filter exhaust gas temperature of 90°C while it operates with a recycling product temperature of 172°C. Crucially, the emissions level is now well within the requirements of Germany’s TA-Air regulations.

Since the plant was installed a number of small modifications have been implemented to further optimise its performance. As a result, Benningoven is now confident that its new counter-flow parallel drum system will prove of widespread interest in the asphalt market as a clean and cost-effective material production solution.

The French-owned2779 Fayat Group meanwhile has invested heavily in new product development and manufacturing at its Italian 273 Marini asphalt plant business. Filippi Baldassari is head of sales and service for Marini and said that the company now has seven manufacturing facilities around the world, allowing it to deliver asphalt plants globally. There are two factories in Italy and one in France, as well as factories in Brazil, China, India and Turkey. This spread of manufacturing allows Marini to offer products developed for the needs of specific local markets. China has been a very successful market for Marini and the firm has delivered more than 400 plants across the country.

As with172 BOMAG, Marini is ensuring it remains one of the technology leaders in the industry and is responding to demand for new and more efficient asphalt plants. Baldassari believes that the asphalt sector is seeing a growing interest in recycling and warm mix technologies, as well as in energy saving overall. He said, “These are the three components to produce asphalt in a profitable way.”

Recycling is a market where the firm is particularly strong and he said, “We have been a technology leader for more than 40 years.”

The firm is able to offer customised solutions for asphalt production such as re-equipping existing plants with new technology for accepting recycled feed materials. He said, “We can save customers millions/year.”

He continued that warm mix asphalt is another trend in the market that is becoming increasingly popular, which Marini is now catering for with its growing range of plants.

The company has made significant steps in designing mobile plants to suit differing needs. The new mobile XPRESS 2500 unit has been developed by Marini to offer contractors the benefits of a highly productive plant that can also be relocated from site to site.

The plant offers a high output and can produce up to 200tonnes/hour, while it can also be made ready for road transport in a short period of time. The wheel-mounted units are 2.5m wide, allowing them to be moved easily by road.

The plant does not require concrete foundations and, instead, the contractor simply has to compact the ground to provide a base for the metal sections on which the plant is then assembled. Installation is made easy by the fact that the plant requires no special lifting equipment. Some of the erection work can be carried out by the same wheeled loader that the contractor then uses to handle the aggregates once the plant has been commissioned.

The XPRESS 2500 features an incorporated hydraulic power unit that means the entire plant can be lifted and positioned for work in the shortest time possible using hydraulic cylinders.

The main frame fits on a semitrailer with three axles and this includes the selection screen and direct discharge system, the bins under the screen, the aggregate metering unit and mixer (2500kg/mix) and the filler and bitumen weigh metering system. It also includes the hot elevator and recovered fines screw conveyor, which is hinged at the centre and allows 90° rotation, as well as the compressed air supply and control cabin.

The standard XPRESS 2500 unit features five mobile cold feeders mounted on a twin axle semitrailer, each 11m3, with the option of pre-fitting RAP feed and the support divider for the wheeled loader.

The dryer drum can produce 200tonnes/hour when using aggregates containing 3% moisture and this also comes on a twin axle, semi-trailer. The burner and the connection channel to the bag filter are preassembled in the factory and ready for use. As with other Marini dryer drums, the unit has a feed system that allows the use of RAP. However, various dryer sizes are available to suit differing production needs. The frame meanwhile features four support legs, each of which rests on a metal base.

The bag filter has over 660 m2 of filtering surface and is mounted on a two axle semi-trailer while the storage bin for the hot recovered fines is located underneath as part of the same assembly. Also on the same frame is the fan extractor along with the excess filler screw. This semi-trailer also features support legs with metal bases while, for ease of installation, the aluminum chimney can be erected without the need for a crane.

The XPRESS 2500 plant is intended to be versatile and can be fitted with a wide range of options to suit differing production requirements. These options include liquid and granular additives, modified bitumen emulsions for warm asphalt production and, on request, a production ramp for foam bitumen. The product discharge meanwhile can be fed directly into trucks or a mobile 20m3 self-erecting deposit silo, which also slots on to a twin axle semi-trailer.

Cold asphalt repair

A special cold asphalt repair technology developed by7951 Macismo International is now meeting customer needs in South Africa. Macismo International entered into a partnership for the technology in 2010, following an approach from National Asphalt, part of South African firm Raubex.

The two firms struck a deal in 2010 and National Asphalt then began to manufacture Macismo’s MacFix cold asphalt product under licence for the South African market. Since that time National Asphalt has become South Africa’s leading cold mix supplier. National Asphalt’s primary output is of hot asphalt, producing more than 1,000,000tonnes/year. The firm is also a leading specialist in warm mix asphalt production in South Africa.

However, the National Cold Asphalt (NCA) product made using the Macfix additive, has also been an integral component and technology partner in developing small businesses in South Africa’s previously disadvantaged communities. The novel properties of the Macfix-based NCA means that end product can be stored and applied in bulk open loads or in bags for more than 24 months. Bulk application optimises profitability for regional and local contractors, which use the material for a wide range of road repair applications across South Africa.

To help develop small businesses and improve road conditions, National Asphalt is supporting black owned enterprises that can manufacture cold mix material throughout each province in South Africa. National Asphalt has developed a compact drum roll mixer that can produce about 1,000tonnes/month to meet local and regional demand.

Called the S’hamba Sonke Programme (SSP), this is aimed at road maintenance on secondary roads and rural roads, with particular emphasis on repairing potholes. The SSP is run through the Provincial Roads Maintenance Grant (PRMG) and consists of three budget components. The largest component enables provinces to expand their maintenance activities. The other components allow provinces to repair roads damaged by floods and to rehabilitate roads in Mpumalanga and Gauteng.

The pilot flagship plant is being launched in the North West Province early next year and all nine provinces should be involved in this programme within the next two to three years. It is envisaged that by combining labour-intensive methodologies with products like Macismo MacFix, many long-term, sustainable jobs will be established, boosting economic stability and also helping improve road infrastructure.

The asphalt sector is constantly looking for ways to optimise production, lower costs and improve product quality and consistency. Competition is fierce in the asphalt plant market, with several of the key companies working hard to develop new and more efficient technologies, as well as equipment that is more versatile and more mobile. Advances have been made with regard to the use of recycled asphalt as well as the production of warm asphalt types. And both warm asphalt and the use of recycled asphalt pavement (RAP) offer benefits with regard to improving sustainability and reducing asphalt production costs.

There are numerous advantages to be gained from the use of RAP in asphalt production, with plant manufacturers in China, Europe, Turkey and the US all now offering innovative solutions. Demand for such equipment has been fuelled by a need to lower production costs as well as to reduce the environmental impact of road construction. And given that RAP contains valuable bitumen and road aggregates that can be reused economically, it is simply good common sense to use this material rather than wasting it.

Many asphalt plants configured to mix RAP into the production process achieve this with the use of parallel drum systems for recycling and this proven technology has been employed by various manufacturers for some time. However, there are shortcomings with conventional parallel flow drum systems, such as high exhaust gas temperatures and high emission levels. With this in mind, German asphalt plant manufacturer

The technique of indirectly heating RAP was developed some years ago but took some years to perfect, with different companies working on a range of solutions. For Benninghoven’s team of development engineers, the biggest challenge was to configure the fan system to ensure effective recirculation and efficient exhaust flow, based on theoretical values. Out of this research, key values were estimated. Using the calculated theoretical values, a system could then be configured while a number of additional features were taken into consideration.

A real challenge to the development engineers was how best to minimise fine particles in the exhaust gas. A simple solution was found, allowing the exhaust gases to first pass through a large expansion chamber where the air speed could be reduced. This stage ensures that the particles fall into a collection hopper and can then be transferred by a screw conveyor back into the hot recycling buffer silo.

When testing commenced, the development engineers from BAM and Benninghoven were encouraged to find that the estimated values for improved emissions performance were actually exceeded. During the testing phase the system was closely monitored, emission tests were taken and samples were analysed. Different mixes were used and modified accordingly, and the processes further optimised with the result that the plant was able to perform exactly as originally planned.

The production tests show that the plant delivers a filter exhaust gas temperature of 90°C while it operates with a recycling product temperature of 172°C. Crucially, the emissions level is now well within the requirements of Germany’s TA-Air regulations.

Since the plant was installed a number of small modifications have been implemented to further optimise its performance. As a result, Benningoven is now confident that its new counter-flow parallel drum system will prove of widespread interest in the asphalt market as a clean and cost-effective material production solution.

The French-owned

As with

Recycling is a market where the firm is particularly strong and he said, “We have been a technology leader for more than 40 years.”

The firm is able to offer customised solutions for asphalt production such as re-equipping existing plants with new technology for accepting recycled feed materials. He said, “We can save customers millions/year.”

He continued that warm mix asphalt is another trend in the market that is becoming increasingly popular, which Marini is now catering for with its growing range of plants.

The company has made significant steps in designing mobile plants to suit differing needs. The new mobile XPRESS 2500 unit has been developed by Marini to offer contractors the benefits of a highly productive plant that can also be relocated from site to site.

The plant offers a high output and can produce up to 200tonnes/hour, while it can also be made ready for road transport in a short period of time. The wheel-mounted units are 2.5m wide, allowing them to be moved easily by road.

The plant does not require concrete foundations and, instead, the contractor simply has to compact the ground to provide a base for the metal sections on which the plant is then assembled. Installation is made easy by the fact that the plant requires no special lifting equipment. Some of the erection work can be carried out by the same wheeled loader that the contractor then uses to handle the aggregates once the plant has been commissioned.

The XPRESS 2500 features an incorporated hydraulic power unit that means the entire plant can be lifted and positioned for work in the shortest time possible using hydraulic cylinders.

The main frame fits on a semitrailer with three axles and this includes the selection screen and direct discharge system, the bins under the screen, the aggregate metering unit and mixer (2500kg/mix) and the filler and bitumen weigh metering system. It also includes the hot elevator and recovered fines screw conveyor, which is hinged at the centre and allows 90° rotation, as well as the compressed air supply and control cabin.

The standard XPRESS 2500 unit features five mobile cold feeders mounted on a twin axle semitrailer, each 11m3, with the option of pre-fitting RAP feed and the support divider for the wheeled loader.

The dryer drum can produce 200tonnes/hour when using aggregates containing 3% moisture and this also comes on a twin axle, semi-trailer. The burner and the connection channel to the bag filter are preassembled in the factory and ready for use. As with other Marini dryer drums, the unit has a feed system that allows the use of RAP. However, various dryer sizes are available to suit differing production needs. The frame meanwhile features four support legs, each of which rests on a metal base.

The bag filter has over 660 m2 of filtering surface and is mounted on a two axle semi-trailer while the storage bin for the hot recovered fines is located underneath as part of the same assembly. Also on the same frame is the fan extractor along with the excess filler screw. This semi-trailer also features support legs with metal bases while, for ease of installation, the aluminum chimney can be erected without the need for a crane.

The XPRESS 2500 plant is intended to be versatile and can be fitted with a wide range of options to suit differing production requirements. These options include liquid and granular additives, modified bitumen emulsions for warm asphalt production and, on request, a production ramp for foam bitumen. The product discharge meanwhile can be fed directly into trucks or a mobile 20m3 self-erecting deposit silo, which also slots on to a twin axle semi-trailer.

Cold asphalt repair

A special cold asphalt repair technology developed by

The two firms struck a deal in 2010 and National Asphalt then began to manufacture Macismo’s MacFix cold asphalt product under licence for the South African market. Since that time National Asphalt has become South Africa’s leading cold mix supplier. National Asphalt’s primary output is of hot asphalt, producing more than 1,000,000tonnes/year. The firm is also a leading specialist in warm mix asphalt production in South Africa.

However, the National Cold Asphalt (NCA) product made using the Macfix additive, has also been an integral component and technology partner in developing small businesses in South Africa’s previously disadvantaged communities. The novel properties of the Macfix-based NCA means that end product can be stored and applied in bulk open loads or in bags for more than 24 months. Bulk application optimises profitability for regional and local contractors, which use the material for a wide range of road repair applications across South Africa.

To help develop small businesses and improve road conditions, National Asphalt is supporting black owned enterprises that can manufacture cold mix material throughout each province in South Africa. National Asphalt has developed a compact drum roll mixer that can produce about 1,000tonnes/month to meet local and regional demand.

Called the S’hamba Sonke Programme (SSP), this is aimed at road maintenance on secondary roads and rural roads, with particular emphasis on repairing potholes. The SSP is run through the Provincial Roads Maintenance Grant (PRMG) and consists of three budget components. The largest component enables provinces to expand their maintenance activities. The other components allow provinces to repair roads damaged by floods and to rehabilitate roads in Mpumalanga and Gauteng.

The pilot flagship plant is being launched in the North West Province early next year and all nine provinces should be involved in this programme within the next two to three years. It is envisaged that by combining labour-intensive methodologies with products like Macismo MacFix, many long-term, sustainable jobs will be established, boosting economic stability and also helping improve road infrastructure.