The new Barauni plant is now producing on-spec road paving bitumen VG-10, 20, 30 and 40 with a capacity of 150,000 TPA. Pörner estimates that around 65% of India’s bitumen is produced in Pörner Biturox plants.

The Biturox process provides IOCL with a choice of feedstock. It is possible to process refinery intermediate products VR (vacuum residues) as well as HVGO (heavy vacuum gas oil) from different crudes of the Middle East. The plant in Barauni is the fourth Biturox plant for IOCL to be licensed by Pörner. The others are at IOCL’s Chennai Refinery in 1994, at the Gujarat Refinery in 2001 and the Mathura Refinery in 2010.

India’s roads have to withstand extreme weather conditions due to monsoons

and broad temperature ranges. It was an important step by the Indian government to introduce bitumen viscosity standards 25 years ago, said Andreas Pörner, Pörner’s managing

director. “These standards enable producers to clearly evaluate bitumen quality,” he said.

His company recently granted its 50th license for bitumen oxidation technology and has been investing continuously in the Biturox process for more than 35 years.

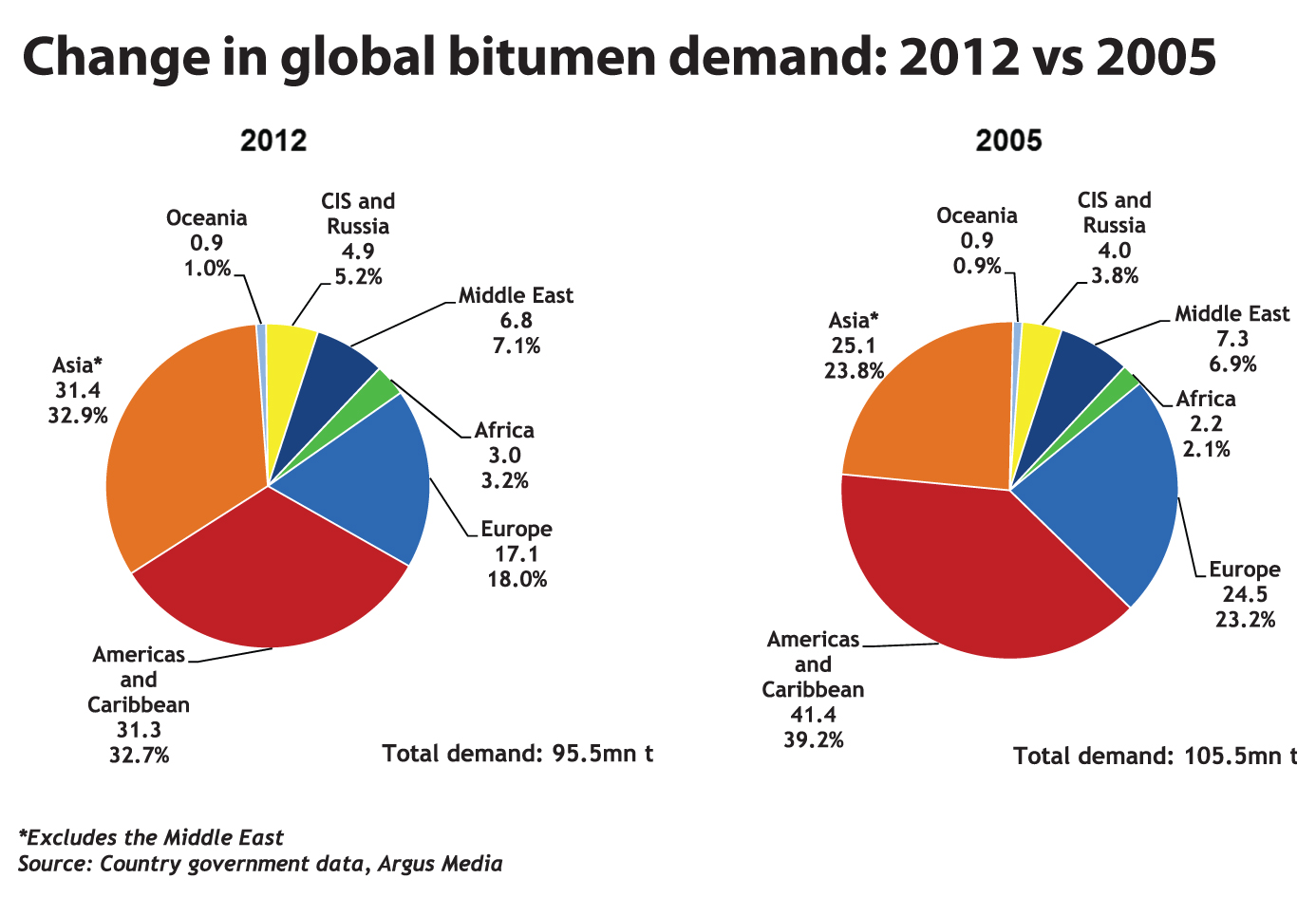

India’s government is focussing on paving thousands more kilometres each year of the country’s 5.5 million kilometres. Ambitious expansion programmes such as the East-West and North-South corridors across India are pushing up bitumen consumption and putting a strain on domestic production.

At the 10th Asian Bitumen Conference in New Delhi in November 2015, Ravikanth Reddy, chief executive of Hotcrete Infrastructure India, said total bitumen sales in India were 4.8 million tonnes. “Based on the ambitious road development plan of the government, there will be an increase in demand of bitumen in India. Presently, 90% of India’s road requirement of bitumen is met by the local oil refiners while the rest is imported.”

Speaking at the same conference, RK Pandey of the