New generation asphalt plants offer key benefits such as being more versatile, more mobile and able to cope with greater quantities of recycled asphalt pavement (RAP) - Mike Woof writes

Several asphalt plant manufacturers are introducing new technologies for 2016. Key developments focus on issues such as the use of recycled asphalt pavement (RAP) and plant mobility, as well as improved mix control. Output quality has been improved by the latest technology, which can allow for much higher quantities of RA

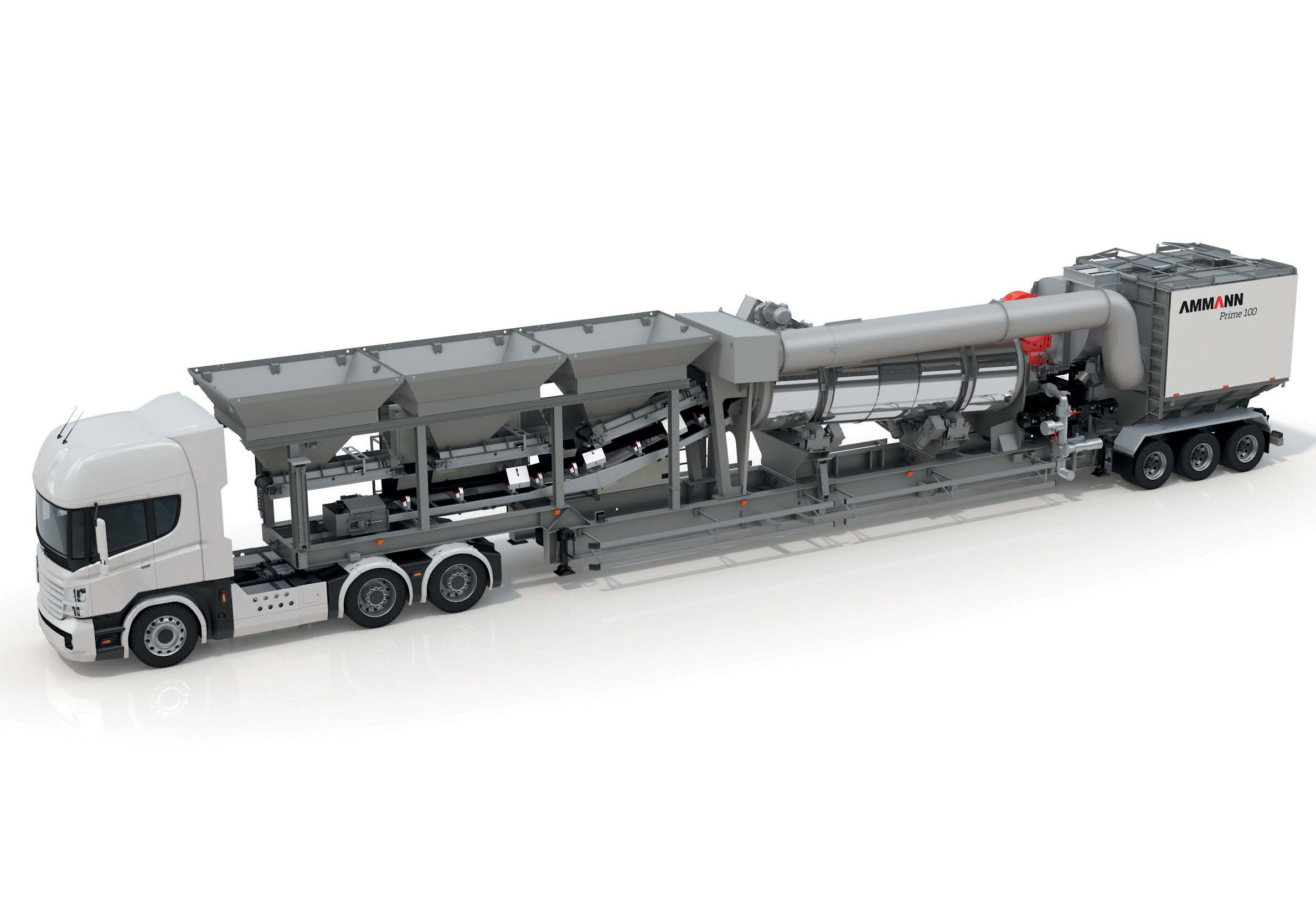

Mobility is a key feature of Ammann’s latest asphalt plant designs

New generation asphalt plants offer key benefits such as being more versatile, more mobile and able to cope with greater quantities of recycled asphalt pavement (RAP) - Mike Woof writes

Several asphalt plant manufacturers are introducing new technologies for 2016. Key developments focus on issues such as the use of recycled asphalt pavement (RAP) and plant mobility, as well as improved mix control. Output quality has been improved by the latest technology, which can allow for much higher quantities of RAP in the mix than with earlier generation equipment.

The new Prime 100 mobile asphalt plant from6791 Ammann is designed for high mobility. This continuous plant can deliver 100tonnes/hour and features all of its main components inside a single standard shipping container. A company spokesperson said, “All you have to do is connect the bitumen tank and an electric power source.”

This is the latest addition to the Prime range and is smaller and more mobile than the proven Prime 140, with its 140tonnes/hour capacity. In addition to its mobility the Prime 100 is compact when assembled, while it takes around one working day to commission on-site. The firm has designed the plant so that it can be set up quickly with only a minimum of site preparation needed. The spokesperson said, “As long as the base has been compacted, it can operate. The plant has everything it needs.”

Meanwhile Ammann says that its QuickBatch plant has been transport-optimised to make it more mobile and versatile. The plant fits into a series of standard shipping containers, making it easy to move from one site to another. In conventional layout it can be carried in nine containers, though additional features may require more units. Typical additions include special equipment for handling RAP and using this in asphalt production. However the firm says that this system also offers customers the benefits of more conventional stationary facilities, such as a high-production capacity. Key core components, including dryer/filter units and mixing tower modules are all fitted inside standard transport containers.

And Ammann says that its latest SolidBatch asphalt plants are designed to combine versatility and reliability. The SolidBatch 140 and SolidBatch 180 offer capacities of 140tonnes/hour and 180tonnes/hour respectively. These units are highly standardised and base models are offered with extra features to expand the range of capabilities, including a RAP circuit.

Now part of the364 Wirtgen Group, 167 Benninghoven is introducing new RAP developments. The firm says that its counterflow parallel drum system with hot gas generator offers considerable benefits for RAP applications. The new design ensures that the recycled material is heated in a counterflow cycle, flowing against the heat source in the drum. The design achieves a high material temperature while lowering exhaust gas temperature.

The material no longer has to be run overheated, which cuts energy use. Head of marketing Lars Henrich said, “The burner is installed in a separate hot gas generator.”

This process is only possible due to the use of the hot gas generator as direct firing would damage the RAP and make it unusable. The burner, hot gas generator, dryer drum, separator cover and circulating air system are said to be precisely balanced. Henrich added that the system also produces low CO2 emissions while allowing a much higher percentage of hot RAP in the mix (up to 90%) than with earlier generation plant designs. Also new is the potential for an additional cold RAP circuit for its plants, using a different elevator than for the hot RAP.

The firm’s new MBA 2000 mobile asphalt mixing plant has five deck screening as standard, compared with conventional units that offer four deck screens. According to Henrich the plant offers a maximum output of up to 160tonnes/hour. Depending on the application, the MBA 2000 can also handle up to 25% of RAP also. Fast set-up and commissioning times are claimed for the unit, as well as high mobility.

Features include effective thermal insulation of the components in the heated section, further boosting efficiency. The wearing plates are said to be designed for a long service life even when using hard stone materials. The machine features a sophisticated control system, the BLS 3000, which is said to offer simple operation. All functions are displayed in the computer animation and controlled with a mouse or keyboard. In addition to fully automatic mode, the control system also offers the option of a manual operating level. This allows the mixing operator to control all actuators and valves separately. The real time representation of the mixing process with graphical and alphanumerical monitoring of set values and actual values is displayed on the monitor.

The2779 Fayat Group claims high mobility and versatility for its RM120 ALLROAD plant. This plant is designed for ease of transport and installation on-site and completes the firm’s ROADMASTER range. Communications executive Paola Pezzi said, “It can recycle up to 40% RAP and it can be equipped for warm mix technology. It is suited to small and medium size plants.”

The plant offers an output of 50-120tonnes/hour and the firm says that it can produce high-quality, hot-mix or warm-mix asphalt, with or without recycled materials. The plant is equipped with the novel RETROFLUX counterflow technology and is designed to meet the needs of a wide array of markets. The firm says that the RM 120 ALLROAD features efficient metering systems and offers customers a reliable and easy-to-use asphalt plant. In addition, the plant also offers the possibility of technical upgrades.

This single-unit plant benefits from good ground clearance and high mobility for its category, which allows customers to operate close to construction sites.

Meanwhile a highly innovative approach to cooling is a key feature of the asphalt plants developed by8346 Günter Papenburg. Employing patented technology developed originally for liquid-fuelled rockets, the firm’s burners are said to be both highly efficient and effective. Because of the novel cooling jacket design, the coal dust-fuelled burners can reach working temperatures more quickly than rival systems according to the firm, making a significant reduction in the amount of fuel required overall. Günter Papenburg has licensed the cooling technology from 4786 LOESCHE, a German producer of coal milling systems. This innovative cooling concept was originally developed by rocket scientist Werner von Braun for use in rocket motors.

Managing director Carsten Weiss claimed that the firm’s burners are also more efficient and consume more of the fuel than rival types, which only burn 90% of the coal dust. He said, “We get an asphalt temperature of 170°C with low emissions and high efficiency.”

Now being used in a new asphalt plant in Germany for a major producer, the burner technology has been extensively tested according to Weiss. This novel plant features a counterflow drum and can handle a high percentage of RAP to produce a high-quality mix. Weiss said that research carried out by Aachen University analysed the thermodynamic performance of the plant and shows the efficiency of the technology now being used by Günter Papenburg. This plant also benefits from a sophisticated computer control package, with new software allowing the producer to use different grades and quantities of RAP in the mix, while delivering high-quality product. The computer can accurately adjust the position of the flights inside the plant so as to control gas flow and optimise operating temperatures.

Highly innovative,1177 LINTEC’s new LEP 95 system is a new, patented warm mix asphalt solution. This can be configured to produce both hot and warm mix asphalt depending on demand at the job site. A major reduction in energy consumption and emissions can be achieved by the LINTEC system working in a temperature range of 95°C-100°C. This unit can be fitted to new or existing plants and is said to produce a smooth and stable foam for an optimum mixing result at low temperatures, while it is reliable and has low maintenance needs.

LINTEC is also offering its versatile and mobile CSD 1200 asphalt plant. This can be transported easily as it comes in standard shipping containers, while also meeting tight safety requirements for operating in major markets. A key operating feature is the patented screen drum technology, which is said to reduce energy consumption by 15%. Other advantages include easy maintenance and a highly advanced control system that allows the operator to make a wide array of mixes to suit differing application requirements. As with other LINTEC plants, the basic CSD 1200 system can be extended with an array of hot storage and recycling solutions (RAP).

The firm offers a compact external hot storage silo with a capacity of 100tonnes that features two chambers, while a bigger version with four chambers has a total asphalt capacity of 270tonnes of asphalt. The compact silo can also be upgraded to 270tonnes by adding additional containers. Both versions are said to feature easy maintenance.

The company can also install its efficient asphalt burners (LAB series), with ratings from 6-24MW. High efficiency is claimed due to electronically controlled combustion, as well as low emissions and high safety standards. They are available for light oil, heavy oil and gas or fuel combinations, while single fuel burners can be retrofitted for dual fuel use.

Several asphalt plant manufacturers are introducing new technologies for 2016. Key developments focus on issues such as the use of recycled asphalt pavement (RAP) and plant mobility, as well as improved mix control. Output quality has been improved by the latest technology, which can allow for much higher quantities of RAP in the mix than with earlier generation equipment.

The new Prime 100 mobile asphalt plant from

This is the latest addition to the Prime range and is smaller and more mobile than the proven Prime 140, with its 140tonnes/hour capacity. In addition to its mobility the Prime 100 is compact when assembled, while it takes around one working day to commission on-site. The firm has designed the plant so that it can be set up quickly with only a minimum of site preparation needed. The spokesperson said, “As long as the base has been compacted, it can operate. The plant has everything it needs.”

Meanwhile Ammann says that its QuickBatch plant has been transport-optimised to make it more mobile and versatile. The plant fits into a series of standard shipping containers, making it easy to move from one site to another. In conventional layout it can be carried in nine containers, though additional features may require more units. Typical additions include special equipment for handling RAP and using this in asphalt production. However the firm says that this system also offers customers the benefits of more conventional stationary facilities, such as a high-production capacity. Key core components, including dryer/filter units and mixing tower modules are all fitted inside standard transport containers.

And Ammann says that its latest SolidBatch asphalt plants are designed to combine versatility and reliability. The SolidBatch 140 and SolidBatch 180 offer capacities of 140tonnes/hour and 180tonnes/hour respectively. These units are highly standardised and base models are offered with extra features to expand the range of capabilities, including a RAP circuit.

Now part of the

The material no longer has to be run overheated, which cuts energy use. Head of marketing Lars Henrich said, “The burner is installed in a separate hot gas generator.”

This process is only possible due to the use of the hot gas generator as direct firing would damage the RAP and make it unusable. The burner, hot gas generator, dryer drum, separator cover and circulating air system are said to be precisely balanced. Henrich added that the system also produces low CO2 emissions while allowing a much higher percentage of hot RAP in the mix (up to 90%) than with earlier generation plant designs. Also new is the potential for an additional cold RAP circuit for its plants, using a different elevator than for the hot RAP.

The firm’s new MBA 2000 mobile asphalt mixing plant has five deck screening as standard, compared with conventional units that offer four deck screens. According to Henrich the plant offers a maximum output of up to 160tonnes/hour. Depending on the application, the MBA 2000 can also handle up to 25% of RAP also. Fast set-up and commissioning times are claimed for the unit, as well as high mobility.

Features include effective thermal insulation of the components in the heated section, further boosting efficiency. The wearing plates are said to be designed for a long service life even when using hard stone materials. The machine features a sophisticated control system, the BLS 3000, which is said to offer simple operation. All functions are displayed in the computer animation and controlled with a mouse or keyboard. In addition to fully automatic mode, the control system also offers the option of a manual operating level. This allows the mixing operator to control all actuators and valves separately. The real time representation of the mixing process with graphical and alphanumerical monitoring of set values and actual values is displayed on the monitor.

The

The plant offers an output of 50-120tonnes/hour and the firm says that it can produce high-quality, hot-mix or warm-mix asphalt, with or without recycled materials. The plant is equipped with the novel RETROFLUX counterflow technology and is designed to meet the needs of a wide array of markets. The firm says that the RM 120 ALLROAD features efficient metering systems and offers customers a reliable and easy-to-use asphalt plant. In addition, the plant also offers the possibility of technical upgrades.

This single-unit plant benefits from good ground clearance and high mobility for its category, which allows customers to operate close to construction sites.

Meanwhile a highly innovative approach to cooling is a key feature of the asphalt plants developed by

Managing director Carsten Weiss claimed that the firm’s burners are also more efficient and consume more of the fuel than rival types, which only burn 90% of the coal dust. He said, “We get an asphalt temperature of 170°C with low emissions and high efficiency.”

Now being used in a new asphalt plant in Germany for a major producer, the burner technology has been extensively tested according to Weiss. This novel plant features a counterflow drum and can handle a high percentage of RAP to produce a high-quality mix. Weiss said that research carried out by Aachen University analysed the thermodynamic performance of the plant and shows the efficiency of the technology now being used by Günter Papenburg. This plant also benefits from a sophisticated computer control package, with new software allowing the producer to use different grades and quantities of RAP in the mix, while delivering high-quality product. The computer can accurately adjust the position of the flights inside the plant so as to control gas flow and optimise operating temperatures.

Highly innovative,

LINTEC is also offering its versatile and mobile CSD 1200 asphalt plant. This can be transported easily as it comes in standard shipping containers, while also meeting tight safety requirements for operating in major markets. A key operating feature is the patented screen drum technology, which is said to reduce energy consumption by 15%. Other advantages include easy maintenance and a highly advanced control system that allows the operator to make a wide array of mixes to suit differing application requirements. As with other LINTEC plants, the basic CSD 1200 system can be extended with an array of hot storage and recycling solutions (RAP).

The firm offers a compact external hot storage silo with a capacity of 100tonnes that features two chambers, while a bigger version with four chambers has a total asphalt capacity of 270tonnes of asphalt. The compact silo can also be upgraded to 270tonnes by adding additional containers. Both versions are said to feature easy maintenance.

The company can also install its efficient asphalt burners (LAB series), with ratings from 6-24MW. High efficiency is claimed due to electronically controlled combustion, as well as low emissions and high safety standards. They are available for light oil, heavy oil and gas or fuel combinations, while single fuel burners can be retrofitted for dual fuel use.