Milling techniques remain one of the most widely used recycling methods

Well-proven, cold milling techniques remain one of the most widely used methods for materials recycling in road construction. Milled road materials can be cleaned up and re-used in both asphalt and concrete highway construction. German firmCompetition is fierce in the sector and Wirtgen's European and US rivals are keen to broaden their ranges and offer improved machines with increased performance. Dynapac is extending its milling range with its new PL500T and PL500TD models. These versatile machines are aimed at the market for planers that can cut a width of 500mm and benefit from a number of key improvements. The new T models are offered with three or four wheels and are said to deliver increased power, improved operator efficiency and greater manoeuvrability than rival machines in the same class.

Increased engine power allows greater productivity and the PL500T offers a maximum cutting depth of 160mm while the PL500TD has a maximum cutting depth of 200mm. Both models are powered by Stage IIIA/Tier 3 compliant diesels from Cummins, with an 82kW engine in the PL500T and a 97kw diesel in the PL500TD.

The operator station has been vibration damped to improve comfort and reduce fatigue while new controls and improved visibility make the machines easier and more accurate to operate. Dynapac's novel hydraulic sealing of the cutter housing is fitted and is said to minimise the accumulation of milled material. Special drums are available for non-standard duties and the machines benefit from a quick-change drum system. Smaller drums with an adapted scraper blade and a side cutting wheel are also available as options for both new models.

Options include a 1m conveyor for feeding into a wheeled loader or a 5.5m conveyor for loading trucks as well as a weather proof canopy, a hydraulically foldable right rear wheel or the Dynapac electronic levelling system.

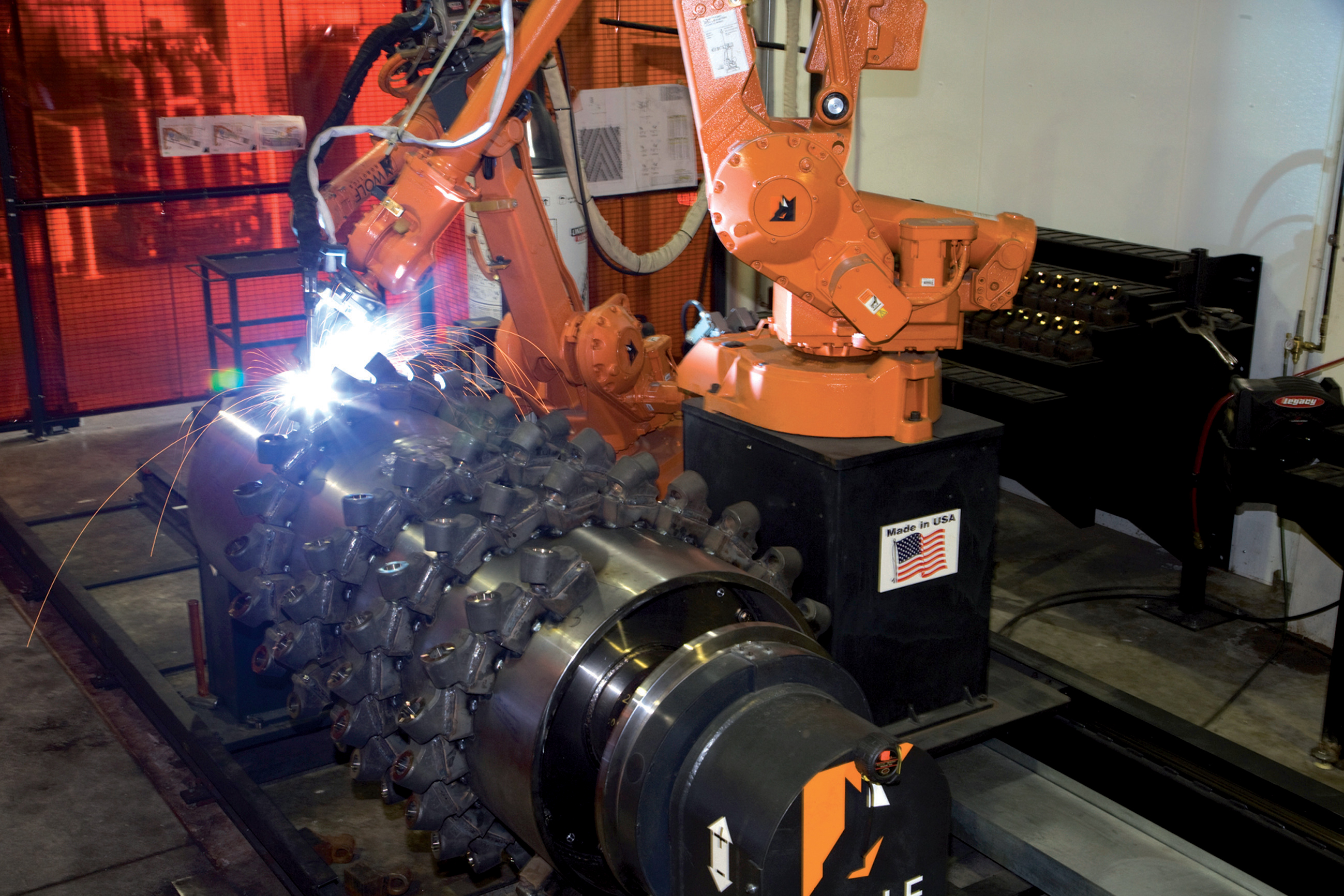

Roadtec has been boosting its milling machine range and now offers four models; the top-of-the-range RX900, the RX700, the RX500 and the most recently introduced RX400. The company also bought up a milling machine drum supplier last year and now offers after-market replacement drums for milling machines and reclaimers as well as utility mills and rumble strip cutters of any brand.

The drum range takes now takes in standard types and specialist models such as profile milling types and segmented models with bolt-on, 4:1 tapered heads. In addition, the company offers a rebuild programme for cutter drums or specialty heads for its own as well as competing machines. The products can be supplied as complete units, ready to install into housing assemblies and Roadtec says that it can fit any tooling system the customer prefers on after-market or rebuilt drums.

However, Roadtec is also offering a comprehensive road recycling option. Its partial depth, cold in-place recycling package is intended to increase efficiency and cut repair costs. This features a production train of machines and is said to offer productivity of up to 450tonnes/hour as well as a blending accuracy of +/- 1%. This is very accurate for the cold recycling sector and according to Roadtec, is one of the most productive cold in-place recycling options on the market.

This technique is best suited to roads where the base is sound and only the surface needs replacing. One conventional method is to overlay the old asphalt with layers of new asphalt, however this has disadvantages as the road height will be increased and underyling faults such as cracking can propagate through to the surface. Another is to use mix plant recycling by milling off the old asphalt, loading it into trucks and carrying it to an asphalt plant and mixing this in with new materials. The (partially) recycled asphalt mix can then be hauled back to the road construction site for repaving in two or more layers.

However Roadtec is now offering another solution in the shape of its partial depth, cold in-place recycling chain. This comprises a top-of-the-line RX-900 milling machine, RT-500 Shuttle Buggy transfer vehicle,

Materials recycling

Consulting engineer Scott Wilson is working with the Waste & Resources Action Programme (WRAP) to encourage construction projects to reduce costs, carbon emissions and improve resource efficiency by using hydraulically bound materials (HBMs). These HBMs include both soil and aggregate mixtures and have been used for over 50 years, mainly within the foundations of major roads. However, the WRAP project is looking to increase the use of this technology as it has the potential to reduce project costs, lower carbon emissions, limit the need for primary aggregates and minimise the materials removed from site. The technique is suitable for trench reinstatement and for use in highway pavement bases, however HBMs are still comparatively underused in many construction markets. Through a programme of regional workshops, WRAP and Scott Wilson intend to increase the potential for HBMs in highway construction.

Chinese recycling

A Chinese municipality is pioneering the use of advanced construction and demolition waste recycling techniques using a track-mounted mobile crusher supplied by Sandvik group company Fintec. The 43.5tonne Fintec 1107 is being used to produce valuable road base material in Xi'an, capital of Shaanxi Province. The Xi'an Municipal Road and Facility Management Bureau is using the machine to help tackle a backlog of construction and demolition waste and to provide a source of high quality and valuable secondary aggregates. During the past three years, the area has seen the demolition of over 2m2 million of buildings and structures, creating thousands of tonnes of construction and demolition waste comprising concrete, stone, brick mortar and sand.

The municipality intends to establish a dedicated company to handle to the processing of construction and demolition waste and to resell the resulting materials to private building and construction companies, landscape and road maintenance contractors. The operation will be geared towards the production of two or three key size fractions with a 40mm product being the most popular for applications in road sub-bases. The Z to achieve an average production in the region of 400,000 tonnes/year.