Some of the major construction equipment manufacturers are introducing new developments for their milling, recycling and stabilisation machine ranges. Increased performance and productivity is claimed across the board, with the new models also complying with the latest emissions requirements.

In the milling machine market, improved performance means that the latest units provide output material that is more consistently sized, allowing it to be recovered and reused as RAP in modern asphalt plants.

Bomag has improved both its milling machines and recycler/stabiliser machines. A key innovation for the firm’s milling equipment range is its new Ion Dust Shield, which is said to reduce dust levels around the machine by 80%. The system ensures that the fine dust particles are charged and stick together. Because they are larger, they do not remain in the air where they would otherwise pose a hazard to inhalation.

The system is now fitted to machines from the firm aimed at use in urban areas, as the risk of dust inhalation by anyone in the vicinity would be highest. However, the company has also said that the system will be fitted to other milling machines in the range.

In addition, Bomag has upgraded its RS650 and RS500 recycler/stabilisers, which feature the firm’s sophisticated FlexMix system. This package ensures optimum mixing as it manages drum speed, water flow rate and material supply.

The RS500 is said to be particularly versatile as its cutter drum can be shifted from one side to another, allowing it to operate close to a barrier or wall for example. The machine can also be used for recycling/stabilising work whether moving forward or backwards.

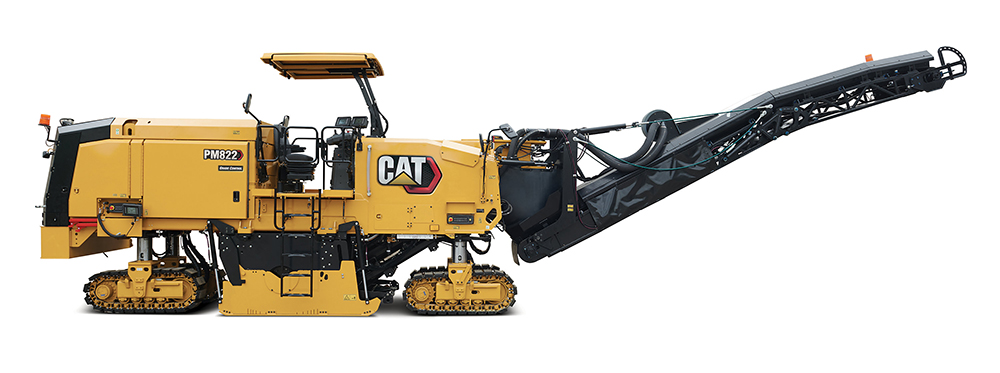

From Caterpillar comes an array of updates to its compact PM310, PM312 and PM313 cold planers as well as the larger PM620, PM622, PM820, PM822 and PM825 milling machines.

The firm’s compact PM300 Series suits small-to-medium job sites where manoeuvrability is required, with both wheeled and tracked variants available for each model. The Cat C9.3 engine now delivers 249kW, a 3% increase, and meets Tier 4 Final and Stage V emissions standards.

The Cat PM300 Series machines have improved visibility features with a sliding operator’s station that extends by up to 215mm to the side, optional camera, and an auxiliary power connector for additional lighting. The optional camera is mounted above the cutter box to improve visibility and can allow closer cuts next to obstacles.

Cat planers are available with the System K milling rotors. Tool spacings of 8mm, 15mm and 18mm are offered to suit varying applications. The firm offers a dual taper retention design, said to hold tool holders in the blocks securely without needing retaining pins or bolts. Reversible paddles and high-strength alloys help extend rotor life.

Optional Cat diamond bits feature a new design for the System K rotors and last up to 80 times longer than conventional carbide. These allow the machine to cut faster and reduce drag, improving fuel economy.

Meanwhile the larger PM620, PM622, PM820, PM822 and PM825 milling machines also meet Tier 4 Final and Stage V emissions standards.

As with the firm’s compact PM300 models, these benefit from the Cat System K milling rotors, with the same spacing options and dual taper retention design, as well as the option of diamond bits.

The firm says that its PM620, PM622, PM820, PM822 and PM825 machines are manoeuvrable despite their output, and they deliver high productivity for half-lane milling work. A key option is the integrated Cat Grade Control system, which allows the user to obtain a high-quality result quickly and efficiently. Using this package ensures that the milled surface is to grade rather than following a set cut depth, providing a significant saving in materials when paving a new surface. The PM820, PM822 and PM825 mills are all powered by Caterpillar’s C18 diesel, rated at 597kW.

Caterpillar is now offering its RM400 rotary mixer, which replaces the previous RM300 model. New features include 19% more power, a revised cab and better manoeuvrability. The 23.5tonne machine can be used for full-depth reclamation and soil stabilisation and delivers a 2.4m cutting width.

Power comes from a Cat C9.3 diesel delivering 311kW, which meets Tier 4 Final and Stage V emissions standards. The all-wheel drive uses four independent drive pumps for maximum torque, traction and speed.

The cab can be slid from left to right, boosting visibility to the tyres and edge of the rotor drum, improving efficiency and productivity. Front and rear facing cameras are fitted as standard and provide extra visibility. Optional side-mounted cameras boost sight lines along the machine for safety. Other cameras and an extra screen can be fitted as options to the front and rear of the rotor housing, giving a better view when cutting close to obstacles.

The machine features an LCD display in the cab providing information on operating functions. The operator can choose from three rotor speeds to suit the application and optimise material gradation. The RM400 can be equipped with a water spray system as well as an emulsion system for versatility and four rotor options are available to suit a range of applications.

Meanwhile, Wirtgen says that its new generation of large milling machines offer a high level of sophistication due to the use of advanced technology. The F series models offer increased milling efficiency for widths from 1.5-2.5m, with cutting depths down to 330mm and power outputs of up to 563kW. These machines also have two-speed powershift transmissions giving a wider range of drum speeds. The new W 210 Fi, W 200 Fi and W 200 F machines benefit from the firm’s CONNECTED MILLING technology, offering a high level of automation and documentation of operating functions.

The firm has developed the machines to meet the increasing need in the construction sector for digitisation of equipment. Wirtgen is combining its WITOS telematics system with its MILL ASSIST and PERFORMANCE TRACKER packages to provide the CONNECTED MILLING system.

Using MILL ASSIST helps an operator to optimise drum speed, water flow and milling speed for lower fuel consumption and pick wear, higher productivity and better finish.

Using the CONNECTED MILLING system meanwhile allows the entire milling process to be recorded digitally in real time. This data can be simulated, providing an analysis of actual working.

Intelligent control of the powershift transmission increases the upper and lower range of possible milling drum speeds, lowering fuel use and tool wear.

In addition, the Wirtgen PERFORMANCE TRACKER package provides tracking of milling performance. When work is complete, a report is automatically generated in Excel and PDF format and is sent by email. All Wirtgen large milling machines built in and after 2010 can be retrofitted with the WPT.

Using special software, the operator receives data on the process and the status of the machine. All LEVEL PRO ACTIVE levelling operations can be carried out from a control panel, which can be mounted on the right or left of the machine.

With the optional Multiple Cutting System (MCS), milling drums of the same milling width but with different tool spacing can be changed, without using any additional tools, in just 15 minutes. Also, the quick-change drum assembly means that different milling widths can be set in just one hour.