Innovative materials testing technology will allow the road sector to boost pavement quality, Mike Woof and Patrick Smith report. With billions being spent on highway construction worldwide, governments are looking to make sure their investments last as long as possible.

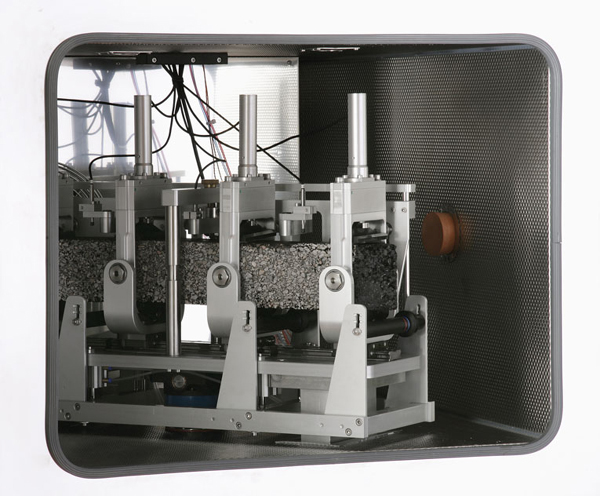

Cooper Technology supplied a Polish road contractor with its recently developed large hydraulic four-point bending machine. This larger beam is for aggregates of more than 20mm

RSS

One way of ensuring this is to carry out laboratory and on site testing of the materials being used, particularly the all-important wearing surface.

Specialist companies now offer the widest possible range of sophisticated products to carry out tests, which can save considerable sums of money in the long run.

For example,1417 Tecnotest, which has been manufacturing machinery and equipment for testing different kinds of building materials for over 40 years, says that while recent advances in asphalt testing have generated demand for new solutions, its past achievements "have more than adequately prepared it to rise to the challenge." Indeed, as asphalt mix performance tests have now become a reality, the company asked itself "how can we overcome such challenges in a field where dynamic tests are the rule? Is our technology applied to static machinery sufficient? "These and other questions are posed all the time at TECNOTEST so our products encounter very few problems." However, the company felt that in the long term it would not pay off to simply duplicate the same products already being offered, not least because it is very unlikely for a duplicate to be better than the original.

"So we decided to enter into strategic alliances with companies already highly specialised in their own fields and which, like TECNOTEST, manufacture machinery with higher performance and durability thanks to a well-balanced combination of innovative as well as tried and tested technology." One such alliance began some years ago with a well-established Texan, US, company, which specialised in manufacturing the Gyratory Compactor B 100, which is used for making asphalt mix specimens, both to the methods and procedures prescribed by current American standards and with TECNOTEST's contribution according to the most recent European standards.

Its compact design makes it ideal for use both in the laboratory and on site.

Also in static testing, the company has its own Multitest T 052/E machine for various types of tests, including Marshall and CBR [California Bearing Ratio] tests.

Because of its capacity to allow various speeds in a continuous range, applications may vary while assuring high accuracy and ease of operation. Now available is the latest addition to the company's range, a new, more economical, analog version of the Multitest, the T 051/B65 multi-speed machine, with six fixed speeds to cover the classic Marshall and CBR test speeds. It is a redesigned version of its popular model T 051.

("Our aim was to produce a more competitive machine while maintaining, unaltered, former specifications and functions. In particular we wanted to maintain the brushless motor, which is the best possible solution to ensure that set speed is maintained independently from load while also guaranteeing precision, reduced noise output and low energy consumption. This type of motor requires little maintenance and so the same solution was also chosen for the reduction gear unit. The remake involved structural re-dimensioning to avoid wasteful excess and is built to last even under adverse conditions," says TECNOTEST.

"The result is totally coherent with TECNOTEST's objectives which have always been to manufacture testing equipment that is meant to have a long life and to work well, the economic factor should therefore be evaluated in the long term perspective.

"Now, if mix analysis, compaction and above all the static tests are already standard practice for TECNOTEST, we cannot claim as much for the new frontier involving dynamic testing, not least considering the recent European standards and the directives regarding the CE marking of bituminous mixes."

Here, a close cooperation began with the US company1636 GCTS, based in Phoenix, Arizona, which already had over 15 years' experience in geotechnical, pavement and rock testing of the dynamic kind, and which had made technology and research applied to the needs of laboratory testing its core business.

"It is to GCTS that we owe their ATM-025 Asphalt Mix Performance Tester. We like to define it as the complete solution for asphalts. It has a modular design so it can be configured for testing asphalt mixes according to the methods and procedures prescribed by the European standards with a mind to CE marking as well as to those prescribed by the American ASTM and The3510 American Association of State Highway and Transportation Officials (AASHTO) standards." TECNOTEST's own contribution for performing advanced tests on road material testing laboratories was launched last year with the roller compaction and wheel-tracking apparatus model B 120/B26, which is different because it offers two solutions in one machine thus enabling slabs of bituminous mixture to be produced at a controlled density which are subsequently subjected to the wheel tracking test using the same apparatus and, after that, to the four-point flexural test using a GCTS machine.

5941 Cooper Technology and its Asian agent Earth Products China, the company has secured an extensive order to supply laboratory equipment to Shangdong Communications and Science Research Institute.

The equipment satisfies the testing requirements for EME [Enrobé à Module Élevé] mix design, the main one being one test per property, and these include gyratory compaction (workability and compactability assessment); immersion compression Duriez Test (water sensitivity); wheel tracking Test (rutting resistance); direct tensile or two-point bending test (stiffness) and two-point bending test (fatigue resistance).

Cooper Technology says that the durability of EMEs has made them highly popular, and there have been heavy demands for this material from countries in Europe, the Maghreb countries and the Americas.

"China is now more interested due to an increase of load aggressiveness, needs for modernisation, durability, environmental effect, and reduced energy consumption. Shandong Communications and Science Research Institute is at the forefront of this movement, and according to Cooper chose the company for its plethora of knowledge and experience in designing and building asphalt testing equipment.

The company has also been involved in ensuring that Poland's €7.57 billion (US$10.4 billion) road budget is best optimised by supplying one contractor with the recently-developed large hydraulic four-point bending machine.

Road construction development advances constantly require the latest equipment to ensure higher and heavier volumes of traffic travels trouble-free down the nation's highways, and the testing of larger aggregate sizes is becoming an ever-growing requirement within the industry.

The company designed the latest generation four-point testing machinery to be able to test samples of varying size. The European standard requirement is that the beam size is three times larger in height and width than the aggregate size.

The constant torque clamping and three-transducer deflection measurement system of the Cooper system can be configured to accept different beam sizes, meaning that the ratio between beam dimensions and maximum aggregate size of test specimens will satisfy the requirements of the relevant European specifications.

Engineers from2741 Eurovia Polska travelled to the UK in December 2010 to undertake operational training and maintenance programmes at the Cooper Academy. "Everything went as planned and the machine will be operational in the first quarter of 2011," says 2356 Viateco, Cooper Technology's Polish distributor.

The company's recently launched auto lifted arm ECO wheel tracker and hydraulic roller compactor are the first of many new products to support the philosophy of energy conservation and optimisation of testing machines, which is at the forefront of the design engineering team's agenda at Cooper Technology.

In addition, Cooper Technology recently launched the world's first fully automated indent test machine with bespoke software that enables both standard tests and research data to be automatically stored and manipulated to further develop global knowledge of asphalt and bitumen properties.

2139 Controls has introduced its new Marshall Compactor Model 76-B4412, which has been improved and modified to increase the working life tests.

"Indeed to prepare each sample between 100-150 blows are required, and this means that, during road construction, hundreds and hundreds of specimens have to be prepared and the compactor has to work without interruption," says Controls.

"We have been producing compactors for many decades, modifying the machine conforming to the information and suggestions coming from our service department and from the field. This latest improvement essentially concerns the sliding mass lifting and release system, more simple and rugged, to further increase the working life of the apparatus.

"A new protection door and the new connection between control panel and machine body make the machine safe and easy to use."

282 Matest, including a roller compactor, wheel tracking machine, polishing equipment and control systems.

Its new A128N accelerated polishing machine has been conceived for the determination of the polished stone value (PSV), ensuring the resistance of road aggregates, paving stones and blocks to the polishing action of vehicle tyres on a road surface.

"The machine is developed and produced in accordance with the most important European standards (EN 1097-8, EN 1341, EN 1342, EN 1343/BS 812:114/NF P18-575/CNR N.105)," says Matest.

Its accelerated polishing machine consists of a wheel, mounting 14 aggregates specimens fastened onto its periphery. During the test the wheel rotates and is in contact with the solid rubber tyre. The polishing action is given by the abrasive charges of corn or flour emery which are continuously and automatically added between the two wheels at a fixed speed using a high-precision feeding mechanism. The flour emery is loaded onto the specimen through a suitable opening, while the water is supplied at a controlled rate through a water container.

The digital control panel, placed on the back side of the machine, allows the test time selection. During the test execution the display shows the remaining time and the speed rotation of the wheel holding the specimens (adjustable from 310-330rpm).

The machine also provides a method of preparing polished stone specimens for the Matest skid resistance (or Pendulum) tester A113 when used in a laboratory environment.

The tester is suitable for site/laboratory applications, and measures road asphalt surface frictional and skid resistance properties, giving a measure of the energy loss when a rubber slider edge is propelled over the surface under test.

The degree the pendulum rises depends on the friction/resistance the rubber slider meets on the road surface. The more friction/resistance, the less the pendulum will rise and the higher will be the Skid Resistance Value (SRV) of the road surface.

The company's latest roller compactor offers accurate measurement, and export manager Massimo Martorini says: "It can simulate what happens on the road." The equipment comes with three moulds, the standard 305x305mm and 305x400mm as well as a special 400x500mm unit. This bigger unit has been developed by Matest to increase the range of testing options available.

"You can use it and prepare for a Marshall test or you can cut some small beams for flexural tests or you can use it for testing in a wheel tracking machine," says Martorini.

The new system features a digital screen, and the user can select dimensions, the mould, the roller and the compaction levels. The compaction can be set to the necessary density or in customisable steps to a specific requirement. Data can then be saved onto USB sticks or SD cards for later analysis.

The new wheel tracking machine can be set to make several different type of tests, with recorded data being stored in the onboard computer for later downloading to a PC for analysis and storage.RSS

Innovative materials testing technology will allow the road sector to boost pavement quality, Mike Woof and Patrick Smith report

With billions being spent on highway construction worldwide, governments are looking to make sure their investments last as long as possible.One way of ensuring this is to carry out laboratory and on site testing of the materials being used, particularly the all-important wearing surface.

Specialist companies now offer the widest possible range of sophisticated products to carry out tests, which can save considerable sums of money in the long run.

For example,

"So we decided to enter into strategic alliances with companies already highly specialised in their own fields and which, like TECNOTEST, manufacture machinery with higher performance and durability thanks to a well-balanced combination of innovative as well as tried and tested technology." One such alliance began some years ago with a well-established Texan, US, company, which specialised in manufacturing the Gyratory Compactor B 100, which is used for making asphalt mix specimens, both to the methods and procedures prescribed by current American standards and with TECNOTEST's contribution according to the most recent European standards.

Its compact design makes it ideal for use both in the laboratory and on site.

Also in static testing, the company has its own Multitest T 052/E machine for various types of tests, including Marshall and CBR [California Bearing Ratio] tests.

Because of its capacity to allow various speeds in a continuous range, applications may vary while assuring high accuracy and ease of operation. Now available is the latest addition to the company's range, a new, more economical, analog version of the Multitest, the T 051/B65 multi-speed machine, with six fixed speeds to cover the classic Marshall and CBR test speeds. It is a redesigned version of its popular model T 051.

("Our aim was to produce a more competitive machine while maintaining, unaltered, former specifications and functions. In particular we wanted to maintain the brushless motor, which is the best possible solution to ensure that set speed is maintained independently from load while also guaranteeing precision, reduced noise output and low energy consumption. This type of motor requires little maintenance and so the same solution was also chosen for the reduction gear unit. The remake involved structural re-dimensioning to avoid wasteful excess and is built to last even under adverse conditions," says TECNOTEST.

"The result is totally coherent with TECNOTEST's objectives which have always been to manufacture testing equipment that is meant to have a long life and to work well, the economic factor should therefore be evaluated in the long term perspective.

"Now, if mix analysis, compaction and above all the static tests are already standard practice for TECNOTEST, we cannot claim as much for the new frontier involving dynamic testing, not least considering the recent European standards and the directives regarding the CE marking of bituminous mixes."

Here, a close cooperation began with the US company

"It is to GCTS that we owe their ATM-025 Asphalt Mix Performance Tester. We like to define it as the complete solution for asphalts. It has a modular design so it can be configured for testing asphalt mixes according to the methods and procedures prescribed by the European standards with a mind to CE marking as well as to those prescribed by the American ASTM and The

Shangdong order

Meanwhile, following a successful EME Conference and Workshop in Nanjing, China, in late 2009, which was co hosted byThe equipment satisfies the testing requirements for EME [Enrobé à Module Élevé] mix design, the main one being one test per property, and these include gyratory compaction (workability and compactability assessment); immersion compression Duriez Test (water sensitivity); wheel tracking Test (rutting resistance); direct tensile or two-point bending test (stiffness) and two-point bending test (fatigue resistance).

Cooper Technology says that the durability of EMEs has made them highly popular, and there have been heavy demands for this material from countries in Europe, the Maghreb countries and the Americas.

"China is now more interested due to an increase of load aggressiveness, needs for modernisation, durability, environmental effect, and reduced energy consumption. Shandong Communications and Science Research Institute is at the forefront of this movement, and according to Cooper chose the company for its plethora of knowledge and experience in designing and building asphalt testing equipment.

The company has also been involved in ensuring that Poland's €7.57 billion (US$10.4 billion) road budget is best optimised by supplying one contractor with the recently-developed large hydraulic four-point bending machine.

Road construction development advances constantly require the latest equipment to ensure higher and heavier volumes of traffic travels trouble-free down the nation's highways, and the testing of larger aggregate sizes is becoming an ever-growing requirement within the industry.

The company designed the latest generation four-point testing machinery to be able to test samples of varying size. The European standard requirement is that the beam size is three times larger in height and width than the aggregate size.

The constant torque clamping and three-transducer deflection measurement system of the Cooper system can be configured to accept different beam sizes, meaning that the ratio between beam dimensions and maximum aggregate size of test specimens will satisfy the requirements of the relevant European specifications.

Engineers from

The company's recently launched auto lifted arm ECO wheel tracker and hydraulic roller compactor are the first of many new products to support the philosophy of energy conservation and optimisation of testing machines, which is at the forefront of the design engineering team's agenda at Cooper Technology.

In addition, Cooper Technology recently launched the world's first fully automated indent test machine with bespoke software that enables both standard tests and research data to be automatically stored and manipulated to further develop global knowledge of asphalt and bitumen properties.

Controls' compactor

The automatic Marshall compactor is one of the most hard working machines in any laboratory, and Italian manufacturer"Indeed to prepare each sample between 100-150 blows are required, and this means that, during road construction, hundreds and hundreds of specimens have to be prepared and the compactor has to work without interruption," says Controls.

"We have been producing compactors for many decades, modifying the machine conforming to the information and suggestions coming from our service department and from the field. This latest improvement essentially concerns the sliding mass lifting and release system, more simple and rugged, to further increase the working life of the apparatus.

"A new protection door and the new connection between control panel and machine body make the machine safe and easy to use."

Polished performance

New testing equipment is available fromIts new A128N accelerated polishing machine has been conceived for the determination of the polished stone value (PSV), ensuring the resistance of road aggregates, paving stones and blocks to the polishing action of vehicle tyres on a road surface.

"The machine is developed and produced in accordance with the most important European standards (EN 1097-8, EN 1341, EN 1342, EN 1343/BS 812:114/NF P18-575/CNR N.105)," says Matest.

Its accelerated polishing machine consists of a wheel, mounting 14 aggregates specimens fastened onto its periphery. During the test the wheel rotates and is in contact with the solid rubber tyre. The polishing action is given by the abrasive charges of corn or flour emery which are continuously and automatically added between the two wheels at a fixed speed using a high-precision feeding mechanism. The flour emery is loaded onto the specimen through a suitable opening, while the water is supplied at a controlled rate through a water container.

The digital control panel, placed on the back side of the machine, allows the test time selection. During the test execution the display shows the remaining time and the speed rotation of the wheel holding the specimens (adjustable from 310-330rpm).

The machine also provides a method of preparing polished stone specimens for the Matest skid resistance (or Pendulum) tester A113 when used in a laboratory environment.

The tester is suitable for site/laboratory applications, and measures road asphalt surface frictional and skid resistance properties, giving a measure of the energy loss when a rubber slider edge is propelled over the surface under test.

The degree the pendulum rises depends on the friction/resistance the rubber slider meets on the road surface. The more friction/resistance, the less the pendulum will rise and the higher will be the Skid Resistance Value (SRV) of the road surface.

The company's latest roller compactor offers accurate measurement, and export manager Massimo Martorini says: "It can simulate what happens on the road." The equipment comes with three moulds, the standard 305x305mm and 305x400mm as well as a special 400x500mm unit. This bigger unit has been developed by Matest to increase the range of testing options available.

"You can use it and prepare for a Marshall test or you can cut some small beams for flexural tests or you can use it for testing in a wheel tracking machine," says Martorini.

The new system features a digital screen, and the user can select dimensions, the mould, the roller and the compaction levels. The compaction can be set to the necessary density or in customisable steps to a specific requirement. Data can then be saved onto USB sticks or SD cards for later analysis.

The new wheel tracking machine can be set to make several different type of tests, with recorded data being stored in the onboard computer for later downloading to a PC for analysis and storage.RSS