Asphalt testing is performed for a variety of reasons by a variety of companies. Patrick Smith reports

Road safety is in the interest of everyone and today it is also an important target shared by the majority of the companies involved in road design and construction. The growing attention paid to this value has had a remarkable effect on the material testing field, encouraged by an increasing market demand for testing solutions as well as by the new technical requirements established by international standards.Asphalt testing is carried out to learn more about a sample of asphalt before, during and after use, and is performed for a variety of reasons by a variety of companies.

Often an asphalt test is carried out for quality control and consistency reasons and this will confirm (or not) that the asphalt contains the materials it is meant to contain, and that the product being produced by a company is of a uniform nature. Such testing can also check asphalt to confirm that it meets the requirements of the application or to inspect asphalt following a road failure to investigate why the asphalt did not withstand normal use.

Companies producing materials testing equipment may have their own laboratories for testing; they will sell the equipment to large companies with laboratories, and often government highway and road departments have their own asphalt testing facilities.

Its research and development team is constantly developing new products as well upgrading existing ones by introducing the newest electronic technologies available on the market.

One of the latest upgrades involves Matest bitumen ductilometers, which are now available in two digital versions with the data acquisition system Cyber-Plus Evolution.

"Ductilometers are conceived to determine bitumen ductility that can be described as the distance to which a briquette of molten bitumen can be extended under controlled conditions, before breaking," says the company.

Matest models consist of a moving carriage travelling along guideways and driven by an electrical motor placed in a large tank fitted with digital thermostat, immersion electric heater, cooling coil for cold water circulation and pump unit.

In addition to the basic model B054, Matest says is now ready to launch two new advanced models, both equipped with the Cyber-Plus Evolution data acquisition and processing system for carrying out a fully automatic test.

"The B055-10 digital ductilometer works automatically at a speed of 50mm/min, and can accept up to three specimens simultaneously.

Cyber-Plus Evolution eight channels control unit allows a user-friendly management and visualisation of data/pictures through the fourcolours, 1/4 VGA and touch-screen display, while the external pen drive or SD cards slots allow the operator to save all the test results without limitation," says Matest.

The high performance B055-20 digital ductilometer is a further evolution of the B055-10 ductilometer, and in addition to the previous model, the B055-20 is equipped with a step motor, providing a variable speed from 1- 50mm/min and with a digital displacement measuring system. Up to four cells can be connected to the ductilometer to test four samples simultaneously. A refrigerating unit can also be supplied on request for testing bitumen specimens with water temperature from +5°C to +25°C.

COOPER LAUNCHES PUMA

"Material development is possible only through laboratory testing, as material providers' knowledge base increases and then more demand is placed on material testing equipment innovators," says the company.

Keith Cooper invented the Nottingham Asphalt Tester (NAT) over 23 years ago, and continual product development via innovation and invention "has ensured Cooper Technology remains strong to this day." The NAT provides a simple, user-friendly means of measuring and assessing the mechanical properties of asphaltic materials, and in June the company is to launch a new patented invention, the Precision Unbound Material Analyser (PUMA).

"Commercial factors are currently driving the need for more effective testing of unbound materials. The revised UK pavement design standard (HD26) allows the use of different foundation materials (classes) affecting the thickness of asphalt layers. Achieving a certain foundation class depends on the stiffness of the materials used, and therefore the ability of roadbuilders to assess the relative strengths of these unbound materials is becoming increasingly important," says Cooper Technology.

"There is growing pressure from contractors to offer improved (and assured) quality foundations for road surfaces, and therefore, a need for a suitable test process for unbound materials.

"Developed as part of a collaborative project between Cooper Technology and the University of Nottingham, PUMA is a new type of laboratory test equipment designed to address these needs and to fill the gap between expensive and complex laboratory tools (such as triaxial cells) and more empirical methods (such as the CBR/California Bearing Ratio test)." The PUMA can also test materials that fall between unbound, hydraulically bound and asphalt. It has been designed as a low-cost, easy-touse and practical tool, but one which is capable of generating scientifically meaningful data (modulus and resistance to permanent deformation), for use in road pavement design. It can be used to test specimens made from granular material, soil or lightly stabilised material, with a maximum particle size of particle 37.5mm.

The company is also highlighting the new hydraulic roller compactor, which extends the recently launched ECO range of energy-saving test equipment supplied by Cooper Technology.

"Roller compaction is considered to be the most suitable laboratory specimen compaction method, and the vibration option offered by Cooper hydraulic roller compactor results in slabs of asphaltic paving materials with properties that most closely simulate those of materials used in the highway.

Slabs can be compacted to target mixture densities using loads that are equivalent to those of full-scale compaction equipment." The CRT-RC-H2 is hydraulically powered and controlled by a programmable logic controller connected to a human machine interface (HMI), which the operator can use to select the number of passes. A manual pressure control is adjusted to set the required load. Its main functions are to produce slabs for wheel tracking tests, bending beam specimens and coring to produce specimens for indirect tensile and axial tests.

TWO, BETTER THAN ONE'

Since the launch of the Dyna-Comp roller compactor and Dyna-Track wheel tracking apparatus at the end of 2008, several dozen have been sold and are operating all over the world with the appreciation of the users, says

"The machines are simple, easy-to-operate and assure great flexibility in the laboratory management.

It is known that the asphalt has to be compacted at 150°C then removed from the machine and thermostatically conditioned to 45- 60°C for the wheel tracking test. The use of two different machines give the important advantage of making possible the preparation of other samples in the compactor," says Controls.

The company's compaction method is based on smooth steel roller compaction, acting directly on the asphalt specimen, simply and quickly combining load and layer thickness control.

"Other methods that, as example, require the interposition of steel plates between the roller and the asphalt sample, cannot assure the same reliability," says Controls.

The 77-B3502 Dyna-Track wheel tracking apparatus offers automatic test control by a data acquisition and processing system; adjustable load cycle frequency, and an uxiliary motor to lower and lift the wheel assembly to and from the specimen.

The 77-B3602 Dyna-Comp roller compactor is pneumatically powered and has combined load and layer thickness control and load per unit roll width equal to the largest site roller.

SUPERPAVE VALIDATION

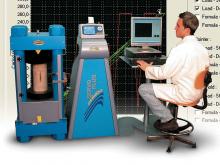

Meanwhile, Interlaken's Asphalt Mix Performance Tester (AMPT) has been selected for use in the US

US states that took part in this pooled-fund study receive an AMPT from the money that they put into the fund in order to learn how to use it for evaluating asphalt mixtures.

Interlaken's AMPT was selected as an approved vendor after vigorous testing by the FHWA.

"It was determined that the Interlaken AMPT met all of the equipment requirements that were provided in NCHRP [National Cooperative Highway Research Programme] 9-29 Simple Performance Tester for Superpave Mix Design," says the company.

Interlaken's AMPT, also known as the Simple Performance Tester, is a computer-controlled hydraulic testing machine to conduct three NCHRP Project 9-29 compressive tests on cylindrical asphalt specimens: flow time test (static creep), a test for permanent deformation based on static creep over flow time strength of asphalt mixtures; flow number test (repeated load), a simple performance test for permanent deformation based on the repeated load test of asphalt mixtures, and the dynamic modulus test (E*), the simple performance test for permanent deformation based on dynamic modulus of asphalt concrete mixtures.