Batsch Dynaweigh says its truck scales HHB01 and HHB02 for dynamic detection of overloaded vehicles has a legal verifiable accuracy of +/- 1% (class 2D). This meets the requirements of the OIML R134 regulations for automatic instruments for weighing road vehicles in motion and measuring axle loads.

For Dynaweigh’s popular HHB01 and HHB02 scales – eight years in development – the total weight and axle loads are recorded automatically during crossing at up to 35km/h.

Several years ago, the scales were installed at the traffic control station of Austria’s A5 northern highway where Austrian authorities use them for monitoring traffic safety and detecting overloaded vehicles.

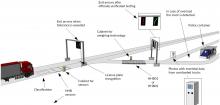

Batsch Dynaweigh, based in Austria, recently added new components for a high-speed WiM system for normal traffic speeds, including classification. There is automatic selection and classification for all cargo-carrying motor vehicles, including tractors with trailers, semi-trailer rigs and vehicles with liquid cargo.

Similar to a radar system, according to the manufacturer, the collected data (total mass, axle load, vehicle type and license plate number) can be forwarded with a photo of the vehicle automatically in real time by means of the Weight Flasher. It then goes into data processing systems or to the control authority.

Advantages over conventional systems include higher accuracy, an increase in test frequency, is fully automatic 24 hours a day, can be used during all seasons and photo documentation of the vehicle and transfer of the approved weighing results are sent to into data processing systems.