In addition, the firm has also supplied systems to customers in other Asian countries including Malaysia, the Philippines and Thailand, as well as Latin America, including Chile, Colombia, Ecuador and Mexico.

For the moment the company has not yet installed the system in the US but a representative from the firm said, “Several states are looking at sites to install this.” In addition, the representative commented, “The owner will set up manufacturing in the US.”

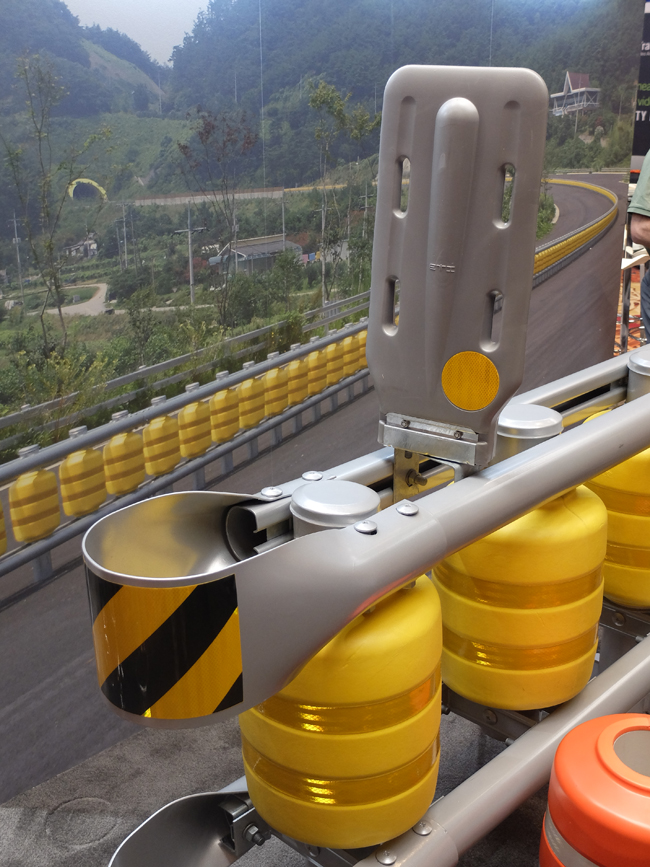

The roller system is best suited to installation at high risk sites on curves or at the entrances or exits to highways. It also can be supplied with an end treatment. The representative said, “The key is in the absorbent material that reduces the impact forces.”

The rollers are made from an ethyl vinyl acetate (EVA) material that is highly shock absorbent, a key design feature. This material is also said to be durable, long lasting and chemically resistant, while not suffering ageing due to UV exposure.

Following an impact with the roller barrier, the vehicle speed is reduced due to the impact absorbent properties of the rollers. The system also deflects vehicles at a shallower angle while causing less damage than conventional barrier types.

ETI says that this means vehicles are more controllable after an impact and less likely to be involved in secondary collisions as a result.

The system is said to be well-suited to the types of vehicles used in the US market and the representative said, “The product works well with SUVs and pick-up trucks.”

The standard colour choice for the rollers is yellow, although other options available from the firm include grey, red and green.

Other novel barrier products from the firm meanwhile include anti-glare screens that can be installed on highway curves as well as exit and entry ramps to prevent the lights from oncoming vehicles dazzling drivers. The firm is also testing a new metal screen system designed to cover over upright barrier posts and improve safety for fallen motorcycle riders.