Various developments are affecting the market for highway barriers - Mike Woof writes

The global market for highway barrier products continues to see the introduction of new products and new standards. Some standards for barriers are also eagerly awaited and clarification is still required of the regulations surrounding motorcycle-safe barrier types. In recognition of the issues concerning bad weather on Europe’s roads in winter periods, a new amendment has been made to the EN1317 standard for safety barriers, which applies to snow removal and specifies how the units perform.In some countries the issue of metals theft is a major problem, and this can range from developing nations such as Kenya to developed countries such as the UK. The high value of scrap metal coupled with unregulated trade in scrap has resulted in thieves making off with barrier sections, presenting major risks to road users. The introduction of plastic or composite barrier products should put paid to this particular issue however.

Taiwanese firm Aplus Molds & Plastics (AMP) is looking for a European distribution partner and will then address the issue of obtaining EN1317 safety ratings for its plastic and composite barrier products. At present the products comply with Taiwan’s requirements for vehicle redirective capabilities and impact performance and have also been supplied into China, the Philippines and South Africa. The polycarbonate and polypropylene barrier sections suit an array of protective requirements. The polypropylene sections are lighter and cheaper than comparable steel components and suit duties on roads with low traffic volumes and speeds.

However, the polycarbonate sections offer greater impact performance and suit guardrail applications on highways. The polycarbonate sections can withstand the impact of a 3.8tonne vehicle striking at angles from 15°-25° and at speeds of up to 100km/h. Weighing just 17kg apiece, the polycarbonate sections are lightweight and easy to handle, allowing them to be installed manually.

Light in weight, this allows more sections to be carried on each delivery vehicle and cuts transport charges. The products are injection molded rather than extruded, maximising strength, while the sections are said to be long lasting due to good UV resistance and are also corrosion-free. Impact performance is also said to be good as the material helps absorb shock, while a minimum working life of 10 years is claimed.

The barrier sections can be recycled and various colours are available to boost conspicuity, while lighting can be fitted if required to boost visibility or provide hazard warnings. The sections also come with integral reflectors, which are colour coded.

In the UK, contractor

It incorporates a barrier rig for VRS and crash impact protection for traffic management. It has also be designed with twin barrier hammers for repairing barriers, an in-built compressor, remote control loader arm, tower lights, generator powerpoints, as well a storage area for cones, signs and VRS components.

The TM/VRS team works with local authorities and contractors across the UK providing services such as repairs to highways after accidents to construction of new roads. The new vehicle started work on an existing

The new guard rail products are the MegaRail bs, d, ed, ek and es variants. These offer restraint capabilities to H1W2, H2W5, H2W8, H1W3 and N2W2 requirements within the European EN1317 standard. The modular nature of the product range means that clients can select from the array of components to suit a system for specific installation requirements.

Italian company

The units have top-mounted, screw-in plugs for filling and drainage plugs at the bottom, make the sections easy to fill and empty before and after use. High impact resistance is claimed as the sand or water-filled plastic provides good absorption properties and the lack of any metal in the construction is said to further improve safety. The units are available in either red or white as standard, while customers can also specify other colours as options and the products also have slots for easy lifting with a forklift truck.

In control

Canadian company

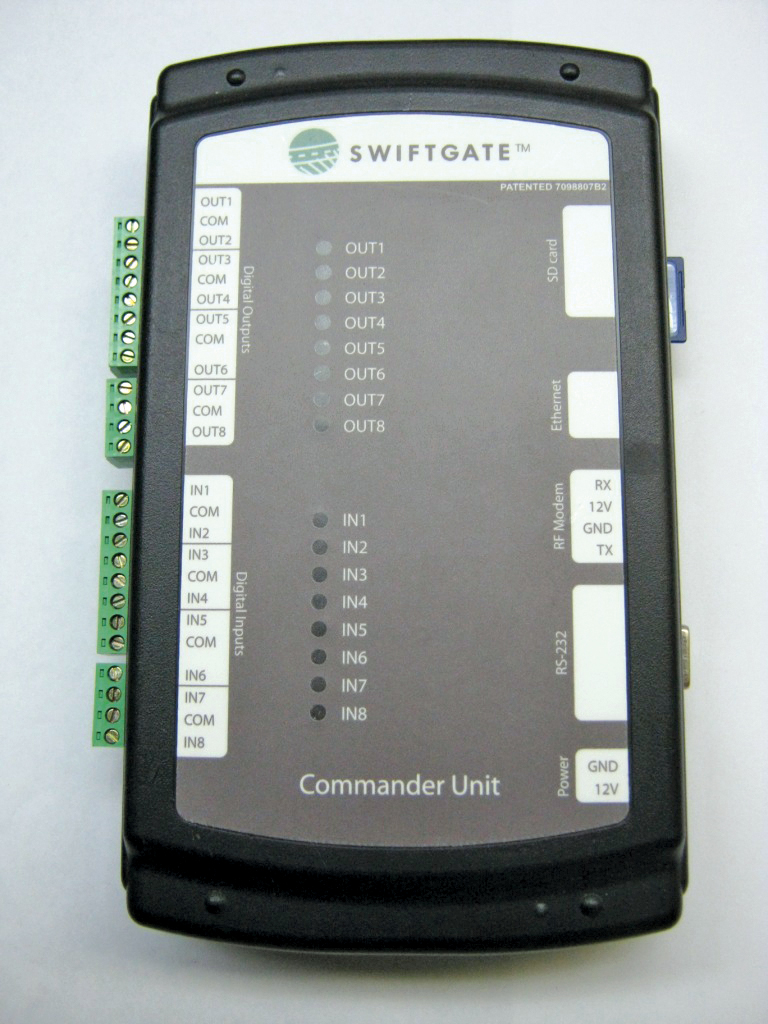

This powerful device is said to interface with existing systems and can be used with SwiftGate automated control gates. The SwiftGate products are in use at the Victoria Park Tunnel in Auckland New Zealand for highway on-ramp control, as well as at the Jacques-Cartier Bridge in Montreal, for reversible lane control. According to Versilis, the COMMANDER meets the need for seamless integration of a variety of different communications solutions as traffic control technology becomes more sophisticated. A new integration capability greatly increases the potential applications for the SwiftGate systems. Using the COMMANDER, automated gates are now easier to use for increasing safety and efficiency for on-ramp/off-ramp control, reversible/HOV lane control, tunnel emergency closure, toll management and other highway applications.