Horizontal and high-tech in-road markings are all being used in a bid to keep roads safe as Patrick Smith reports.

Many modern roads, especially in urban areas, are equipped with the latest technology to guide drivers and, more importantly, improve safety.

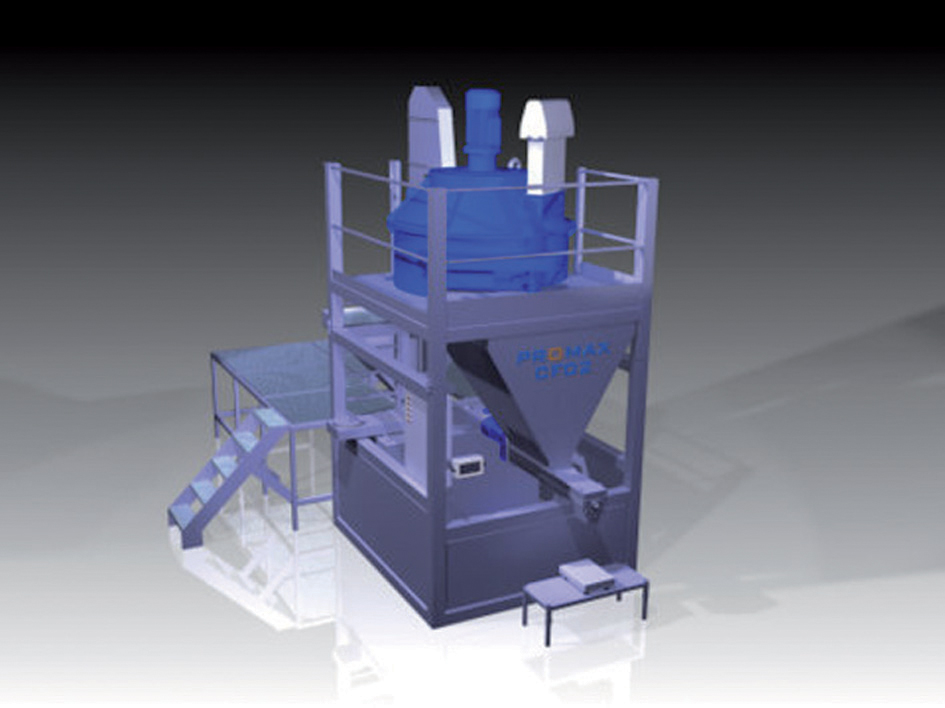

PROMAX Industries' new thermoplastic plant, the PROMAX CF02

Horizontal and high-tech in-road markings are all being used in a bid to keep roads safe as Patrick Smith reports

Many modern roads, especially in urban areas, are equipped with the latest technology to guide drivers and, more importantly, improve safety. However, among the most effective devices for achieving both of these aims IS still road markings whether, for example, they are painted; hot (or cold) thermoplastic with reflective glass beads, applied using special spray machines, temporary road markings or special road studs, which are increasingly being used at high danger areas.The importance of clear, highly visible markings is best seen in the dark, particularly when it is wet or misty making the accident risk even higher. It is worth repeating that roughly one-third of traffic accidents involving injuries happen at night, although only 20% of all traffic flows after dark.

"A well-marked road is a safe road. And for a road marking contractor, a job well done is a profitable one. Having to cope with variables such as changing weather conditions, traffic density and travel time, operators need equipment that is suited to the job and performs well, time after time.

"

The company also points out that councils and road marking authorities are demanding higher and higher retroreflectivity [materials having the ability to return/retro most of the light back to its originating light source], especially under wet conditions, and this is where it is essential to have equipment for testing that the product delivers.

DELTA RetroSign upgraded

At present DELTA offers RetroSign GR1 with one main observation angle (0.2o ASTM standard and 0.33o CEN standard) and RetroSign GR3 with three observation angles (0.5o and 1.0o in addition to the main observation angle) allowing a more complete view of the retroreflection level also for trucks and large vehicles.

The recent generation of RetroSign has offered a number of add-ons to the base instrument such as GPS for location identification, Bluetooth for wireless communication, RFID reader for RFID tags and an extension pole for the measurement of tall signs.

"As a part of a management system the market is increasingly asking for access to a barcode reader solution. DELTA has finished the development of such a solution, and RetroSign instruments are now available with barcode reader," says the Danish company.

"When measuring with the barcode reader on, RetroSign will first ask for measurement of the barcode followed by retroreflection measurements linking the two types of measurement data."

Meanwhile, fellow Danish company

According to PROMAX, which also supplies customers with a wide range of chemicals and raw materials, such as resin, rosin resin, glass beads, EVA, and rubber, CFO2 has already met with wide interest among customers, and one has already been sold to Russia.

"PROMAX CFO2 gives our customers the perfect tool to be competitive on the market, by securing thermoplastic quality, and it offers a fast return of the investment," says PROMAX.

The new PROMAX CFO2 production plant, which is 6.3m long, 3.2m wide and 4.5m high, is orientated directly to clients with production requirement up to 1.5tonnes/hour. It is designed as a module system, which allows the company to erect and put the plant into operation in two working days.

The computer-controlled batching system with more than 100 recipe options oversees the quality of each manufactured batch.

"The plant can be installed in the smallest manufacturing facility, thanks to its compact design. Electric power is the only external facility required to put it into full production mode."

PPI is an ISO 9001: 2008 certified company and a past winner of The Prime Minister's Exports Award in Thailand as The Most Distinguished Brand.

"Our company uses the latest technology in manufacturing road marking materials and has a professional technical laboratory fully equipped with the latest apparatus and production facilities. Our staff is fully trained using primarily production equipment imported from the USA, Europe and Japan to ensure the best quality products," says the company.

The company's main objective is to continuously obtain customers satisfaction by giving them the best quality products and services capable of competing in the international market. PPI is engaged in continuous research and development for new products in order to meet our customers' requirements for marking materials that are suited to all climatic condition around the world." In another development,

"Herr Günther from Bauhof Kitzingen in Germany sent pictures of a pedestrian crossing from Kitzingen. The application of PREMARK pedestrian lines was done with Viaxi on the 7 June, 2006. The condition some four years later shows PREMARK preformed thermoplastic road marking combined with Viaxi primer can be the solution for marking city areas with cobble stones," says Geveko.

Geveko has also contributed to the Danish pavilion at Expo 2010 in Shanghai, China, by using preformed thermoplastic PREMARK Anti-Skid to mark a blue bicycle track, making it possible for visitors to ride city bikes from Copenhagen (the Little Mermaid, flown from Copenhagen, is the main attraction).

The 550m long bicycle track in Shanghai is marked out using the PREMARK Anti-Skid, which was pre-shaped and pre-cut in order to fit precisely and to perform with a high skid resistance.

Airless technology

Meanwhile, German road marking machine manufacturerTorsten Pape, head of sales and marketing at HOFMANN says that the decisive advantages of the new airless technology are that it only needs one storage container, and premixing is omitted because the hardener is fed directly into the spray gun just milliseconds before the spraying procedure and the total purging agent consumption is reduced to a fraction.

And in 2009 its new generation of pumps for highly viscous materials, such as two-component friction plastics, went into production, "enabling the production of accurate Type II markings of all types." Combined markings, consisting of continuous and broken lines, can be also be produced in one pass using a doubler.

"HOFMANN was the first company on the global market in the sector of agglomerate markings. The first machine application with a compressed air pulse discharge procedure followed in 1984 (the SPOTFLEX system)," says Pape.

"HOFMANN expands with follow-up inventions, and the result is an extremely modular system, quick-change capability and fail-safe lockability of every individual spraying nozzle, minimal detergent consumption, accurate adjustability and quantity stabilisation as well as an enormous increase in the application speed. With a 2cm line distance, the new HOFMANN system can achieve speeds up to 5km/hour. An expanded system will enable up to 10km/hour, which corresponds to 140 lines/sec."

Remodelled range

Thailand companyUnimark says that the latest addition to the range, the Highway 300/300 airless cold paint machine is suitable for general road marking and airport marking. It has two agitated tanks that are suitable for water or solvent paint systems and two high-pressure hydraulic paint pumps that can deliver high-speed single lane marking or two-colour markings simultaneously as used on airport taxiways.

The company says the control system can control the line width for extrusion and all lining patterns without the operator stopping or moving from his position.