Road marking manufacturers have many innovative new products either currently being used on major highways or set to be made available within the next couple of years. Guy Woodford reports

Daan Roosegaarde, an artist, and Hans Goris, a manager at Dutch construction and infrastructure firmOne innovation involves painting road markings with glow-in-the-dark paint.

“One day I was sitting in a car on a highway and wondering why we spend millions on cars making them more sustainable, when we have done nothing for sustainability of roads,” said Roosegaarde.

“I gave a talk for the [Dutch] government about innovation and I didn’t know that representatives from Heijmans were sitting in the audience. They told me that the company needed to innovate to create added value in the future.”

The initial post-talk conversation led to Heijmans making a deal with Roosegaarde to develop six of his ideas, including his glow-in-the-dark painted road markings, into commercially viable products. Roosegaarde said that he got Heijmans to look at video films of jellyfish, focusing on how they gave off light without being able to draw on power-generating technology such as solar panels.

“We decided to team up with a [Dutch] paint manufacturer and combine photoluminescence and responsive paint. The resulting paints charge up in the daytime and provide eight to ten hours' glow [light] at night,” explained Roosegaarde. “This is much friendlier for the environment, plants and animals, and you can see it [painted road markings]."

Currently being tested in laboratory conditions, the glow-in-the-dark paint road markings will be tested along a short stretch of provincial road in the Netherlands in November 2013.

“We are looking at aspects such as [the paint’s] skid resistance, and its ability to withstand salt ingress,” said Goris.

“The idea of the [glow-in-the-dark paint] road markings is that we can use them in an area where there’s no public lighting. It’s a simple, cost-effective measure, compared to using a combination of existing road markings and street lighting.

“The glow-in-the-dark painted road markings can also help people along in the direction they wish to go as an alternative to cat's eyes.”

Goris said that the strontium aluminate chemical element in the developmental glow-in-the dark paint road markings, which allows atoms in the paint to emit light more slowly over time, are a modern variation of the use of radium after World War Two to make clock dials visible in the dark.

Roosegaarde said that while putting glow-in-the-dark paint on existing urban and rural road markings would have an initial cost, long-term savings could be found through the removal of road signs and markings that require costly electric-powered lighting to be visible at night.

He added, “Governments are shutting down street lights at night [to save money] and we need things that are sustainable.”

Goris said that representatives from Nordic and African countries had expressed great interest in the glow-in-the-dark paint road markings and, next year, the fully tested markings are due to be piloted in the world’s second most populated country.

“India has a huge problem with safety and electricity goes down all the time. It would be a very nice setting to have the first glowing road markings,” said Roosegaarde.

Goris said that, depending on the success of tests and pilots, the glow-in-the-dark paint road markings could be available for export from 2015.

Roosegaarde and Goris are also working on a temperature-sensitive paint mixture to create giant snowflake-shaped warning signs on roads.

The patterns change from being transparent to colour when sections of the road become cold, warning that they could be slippery due to the presence of ice.

“We did not want to put expensive equipment in the road. We only want to have information displayed that is valid, and only shown when necessary,” said Roosegaarde. “I don’t have the patience to wait for the building of new roads. We need to do this now. Only the road knows if it’s slippery. You can’t know just from being in a car.”

Goris said that the snowflake-shaped warning signs would be best suited to small yet potentially dangerous stretches of road, such as to warn cyclists looking to make a turn at traffic intersections, and motorists approaching highway viaducts.

The snowflake-shaped warning signs on roads are being piloted in the Netherlands later this year, and may be commercially available before the end of 2013.

With tough, wear-resistant polymers, 3M claims that Series 5000 has the best dimensional stability of any plural-component product on a wide variety of substrates. It is said to demonstrate excellent adhesion, superior stability and resistance to discoloration. Series 5000 is also said to have outstanding colour stability and is available with versatile optics package configurations, including wet-reflective options for all-weather performance.

Series 5000 features a low viscosity, making it easy to pump, pour and apply, and it can be applied at temperatures as low as 30°F. It is said to have the fastest cure time of any plural component product and is track-free in less than two minutes over the entire application temperature range. Like all 3M pavement markings, Series 5000 is backed by 3M’s technical and customer service.

PROMAX has developed the SP60 factory: a new, upgraded, cost-efficient manufacturing system for pre-formed thermoplastic road markings.

The Danish firm said that its SP60 can manufacture up to 1,200 ready-made thermoplastic sheets over an eight-hour period with a minimum of labour. To make this output possible, PROMAX has developed a generation of thermoplastic preheaters, said to take temperature controls to a new, higher level. The inner top and bottom surface temperature of the heater are said to be kept equal, without any use of mechanical oil circulation in the transfer oil jacket. This special featured preheater together with advanced thermoplastic chemistry makes it possible to blend and apply the thermoplastic at the same low temperature. This concept, says Promax, significantly increases production capacity by doing away with wasted time for extra heating requirements and inconvenient cooling of the thermoplastic prior to application. Promax claimed that the SP60 can produce up to 14 metres of thermoplastic sheets each minute.

The thermoplastic sign material contains premix and drop-on glass beads for maintaining the required new and lifetime retro reflection values. During sheet production the system is operating with four preselected colours – and any colour shift can be made during a 10-minute resetting period.

The SP60 comes with an automatic controlled application system, said to provide a perfect surface structure on the final road marking product. Due to the new preheaters and the advanced system for heating and application of reflex and anti-skid material, no further treatment of the thermoplastic road marking is required after application.

PROMAX assist with setting up the required chemical formulations for the thermoplastic material so that it meets the domestic and export requirement.

Specialist PROMAX staff can install and begin operation of an SP60 within two weeks.

Satisfied customers in the Middle East and in Europe, in countries such as Romania, are said by PROMAX to be already using its SP60 model as their preferred manufacturing system for pre-formed thermoplastic signs.

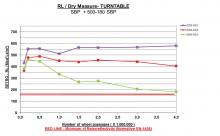

Crucially, the greater the optical retroreflection of road markings, the more visible they are to drivers. DELTA said that its latest LTL-M mobile retroreflectometer for assessing road marking performance has improved accuracy due to its use of new patented technology. Its accuracy is now said by DELTA to be as accurate as readings taken with traditional hand-held devices such as the Danish firm’s own LTL-X model. The LTL-M is said to be a major advance on first generation retroreflectometers that, according to DELTA, were up to 40% less accurate due to vehicle movement changes and wind and vehicle load variations affecting measurement geometry.

The LTL-M measures the detailed cross-sectional retroreflection of the markings. DELTA said that as many markings have strong transversal variation, a reading taken by hand-held instruments with a 4–5cm wide measurement field in the centre does not represent the true visibility. The LTL-M gives a detailed analysis of the variation that can be correlated to the true visibility as the driver sees the marking, or to a middle section for correlation to a hand-held instrument.

The LTL-M also offers the chance to measure accurate white and yellow markings automatically without recalibration. Other key features include good linearity up to at least 2,000mcd/m² 1x, easy field calibration traceable to national standards and the suppression of daylight to retain measurement accuracy.

Schmidt-Thie-Plast has been using one of

Effective hot-oil heating of all major parts of the BM T 250-2 extruder is said by Borum to ensure that the thermoplastic material does not stiffen and set inside it. A continuous circulation of the thermoplastic material inside the model is said to ensure its homogenous viscosity. While this improves the quality of the line, a bigger plus is said by Borum to be the great wear reduction that this continuous circulation achieves.

“The acquisition has high strategic importance, as Geveko during the last years gradually has increased its presence in selected markets outside Europe, among others in the Middle East, North Africa and South America. These marketing efforts will continue and hopefully longterm contribute to increased sale of road-marking products,” said Göran Eklund, Geveko CEO and managing director.

Meanwhile, in Belgium, several artists from Vorselaar have used Geveko’s

Echostar performer

On a road near Sarrebourg, north east France, a certified system P5R3 (1,000,000 rollovers and 150mcd/m2/lux on the official French road test field) using the RAPIDO VEGA waterborne paint produced by SAR (Société d'Applications Routières) and the Echostar 2 WBP Be Fast was applied with an unmodified airless machine.

Relative humidity was high, according to Sovitec, while temperature remained lower than 10°C. The road markings are said to have dried in less than half of the time required with the use of the classical Echostar WBP system, with the stripes not suffering any tracking or pick-up after being driven over by traffic.

The Echostar 2 WBP Be Fast system was also successfully applied by a contractor with paint from Belgian firm ACB to create road markings for use during last year’s London Olympics.

Speaking about Echostar 2 WBP Be Fast, a Sovitec spokesperson said, “When applied, the marking can leave a strange impression at a first glance since the additional product [Fastrack QS2] is slightly coloured. This additive behaves as if it were absorbing the water contained in the paint, hence fastening the drying effect of the system while also decreasing the risk for further road markings washing out. When the paint is dry, the coloured particles are removed by the traffic and road markings appear as white as if applied only with classical beads. The waterborne paint gets back finally to its original white colour in a few hours.”

The spokesperson said that while the night visibility offered by the Echostar WBP Be Fast family road markings are only slightly inferior compared to road markings applied with classical Echostar WBP, their drying time was more than 50% faster than the classical glass beads at up to 95% relative humidity. This allows contractors to install Echostart WBP Be Fast family road markings consistently over the course of the road markings season.