An Innovative road marking system helping to boost public transport in a major South American city, and road marking analytic technology robust enough to withstand damage in heavy rain are among products examined by Guy Woodford

Around 25km was covered in the first phase of the DEGAROUTE-based bus lane project. The application began in September 2012 and was completed in December 2012.The next project phase was due to be determined after the initial application. The entire project is earmarked for completion by December 2013.

Evonik says it beat off competition from seven other companies to secure their part in the Santiago public transport system upgrade. They were initially one of eight firms asked to apply four different types of area marking technologies on a surface area covering 250m².

DEGAROUTE –based cold plastic and a competing thermoplastic system were then said by Evonik to have gone head-to-head in further tests on a 2,500m² surface area. Evonik says its DEGAROUTE system was chosen due to its outstanding durability.

A leading company in the use of glass beads for road markings, Sovitec describes Star Pilot as a multi-parameters analyses program and decision tool that helps customers choose the right horizontal road marking system for their specific needs.

A company spokesperson said: “White stripes are simple, but it is in fact a very technical system that includes many parameters, such as road surface, marking materials, application, performance requirements and legislation.

“Star Pilot will test all the relevant parameters of the systems you want to apply.

“Step by step, from paint recipe analysis to certifications, our road specialists and our external scientific centres and partners will perform tests on road surface characteristics, chemical surface treatment, analysis of raw materials, thickness of the paints, costs of formulas. Each party will contribute to the analyses.”

In its laboratories, Sovitec analyses the best glass beads solution to use.

The firm tests the paint and the drop on beads system, while its test team and their partners test the application equipment.

“Star Pilot will make conjoint analyses for you to understand the trade-offs and decide what system to use,” added the Sovitec spokesperson.

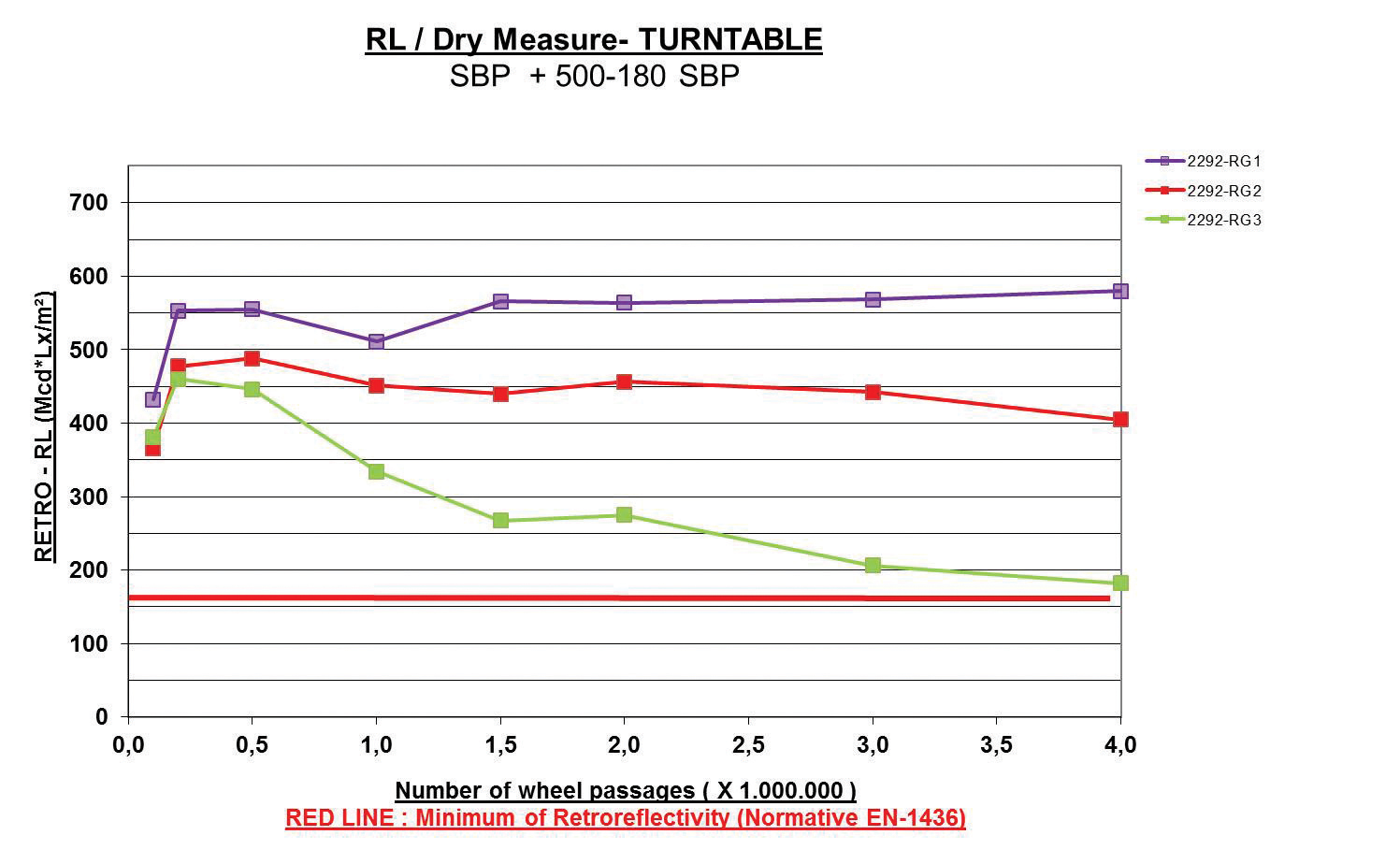

“To guarantee the product resistance, Sovitec tests each formula on the turntable at AETEC in Madrid. This equipment simulates the wear which road markings are subjected to, under the same conditions as in real traffic.”

Due to Sovitec’s exclusive licence to use multi-structured plates, replicating the roughness of different road surfaces, the company claims the cost of the analysis process will be reduced versus an official process.

Each step of the Star Pilot analysis program is said to help customers achieve numerous certifications in different markets, either through the turntable simulator, or through road trials.

“Star Pilot reports and recommendations are not one-off: you can use them over and over again to become the reference, to train new teams, to set targets for your researchers, to increase performances, to leave your competitors behind whether you are road authorities, applicators, paint producers, or raw material suppliers,” added the Sovitec spokesperson.

Thanks to what Sovitec says is due to the initial success of its Star Pilot analyses program, the company teamed up with Dow to create Echostar Be Fast: described as a “revolutionary” product designed to work in difficult road marking application conditions such as high humidity, low temperature, and thick layer.

On colder mornings or wetter days, Echostar Be Fast, used in combination with the right waterborne paints, is said by Sovitec to enable a safe application of waterborne road markings.

This product family, which Sovitec says has already been successfully used in core markets such as France and the UK, is said to be applied like any other traditional drop-on beads and reduces the risk of the paint being washed out by rain soon after the application. Said by Sovitec to be easy to apply, acting like a sponge, the Echostar Be Fast beads dropped on waterborne paints is said to considerably accelerate the drying process.

Reducing the drying time of the system is said to allow the applicator to free up the road faster. Although it is not yet fully dry, the paint film is already resistant to wheel roll-overs and to the rain that may fall soon after application. After water evaporates from the paint; a strong film is said to be formed, leaving the road marking ready to endure the weather of the seasons and the traffic.

“Excellent performance results for Echostar Be Fast were obtained during applications in the UK in appalling weather conditions during November 2012,” said the Sovitec spokesperson. The spokesperson said the most eye catching application of Echostar Be Fast to date has been on the Olympic Lanes for last summer’s London Olympics.

DELTA says that its LTL-M mobile retroreflectometer for measuring retroreflection of pavement markings was “extensively” used in 2012, particularly in the Nordic countries, North America and Oceania, following its launch in 2011.

LTL-M employs a new technology making use of a flash system and digital camera technology.

After being used on thousands of kilometres of roads, DELTA says its LTL-M system has proven its ability to measure accurately under various driving, climatic and road conditions – even in rugged environments.

Given the external mount of the sensor systems (camera) adjacent to the vehicle and located only inches above ground, Delta says a few minor accidents during use have been unavoidable. However, even then, the claimed rugged design of the LTL-M system is said to have proven its value.

According to DELTA, one customer said the LTL-M system kept working after the front-glass of a sensor box broke as the vehicle the system was attached to was being driven many kilometres through rain. The glass was only replaced, and the inside of the sensor box dried, when the problem was identified.

Another customer’s LTL-M sensor unit is said to have hit an obstacle and broken off the vehicle it was attached too during one particular application.

However, DELTA says its customer reported that the LTL-M system still worked fine after minor repair.

A new

Leading road marking company

Held between 20th and 22nd November, 2012 at Bruntingthorpe Proving Ground, in the English county Leicestershire, SiB visitors were treated to a number of impressive demonstrations of new ideas and technology in a ‘real-life’ road-side setting, without the safety concerns of being on an actual road. The track that delegates are driven around, in a variety of vehicles, recreates a variety of road layouts in different situations and locations, and gave everyone a chance to see how products perform both by day and at night.

3M highlighted some new developments of its own, alongside the more familiar signing materials, both on the track and in the exhibition hall. Delegates began their ride around the track with a comparison of signs made with 3M temporary High Intensity Prismatic (HIP) sheeting and 3M High Intensity Beaded (HIB) sheeting.

HIB is discontinued but was displayed at SiB as an example of the old style Class 2 beaded material. The company also demonstrated the use of 3M Diamond Grade Fluorescent DG³ Reflective Sheeting for temporary signs, both on its own, and in comparison with HIB.

Further on round the track, delegates compared the notable differences between permanent HIP and HIB. Less obvious, claims 3M, are the environmental benefits of HIP, which is made by a process that produces less waste, less emissions of harmful gases and requires less energy than the process used for glass beaded materials.

Further environmental and cost savings are said by 3M to be achieved with high performance materials when there is no need for external illumination, which, the company says, was what it aimed to demonstrate at subsequent stages around the track.

A comparison of unlit DG³ and fluorescent DG³ signs alongside illuminated HIB signs, was said to show how permanent and temporary signing can actually be enhanced by using the right materials without external lighting.

The edge of the track was also lined with 3M’s Stamark permanent road marking tapes and 290 roads studs. Both of these products are said by 3M to have a proven track record, and aside from exceptional brightness, both benefit from ease of application. A separate area of the exhibition space was used to demonstrate how quickly roads can be marked with Stamark tape.

Vehicles themselves - a mixture of cars, mini buses and HGVs – were all marked up with 3M materials according to the requirements of Chapter 8 and ECE104. 3M says its tape can be used on a wide range of highway maintenance vehicles, emergency service vehicles, and commercial vehicles as high conspicuity marking tape.

Geveko makes a wider PREMARK

Firmly established as part of the road marking landscape on highways in Europe, USA and Australia, Geveko’s PREMARK preformed thermoplastic road marking is being increasingly used to help guide traffic in the North Africa, Middle East and Gulf regions.

A recent example is the introduction of Persian words, a car symbol and an ETC logo to help guide the traffic and increase its flow at a toll station in Iran. Meanwhile in Ajman, in the United Arab Emirates, PREMARK is now used on horizontal speed limit signs to make drivers aware of the 60km/h speed limit in an attempt to reduce the number of accidents. Finally, in Egypt truck signs featuring PREMARK are helping keep trucks in the right lanes and informing them of speed limits on the northbound route of a highway between Cairo and Alexandria.

3i Traffic at work in NZ and Germany

3i Traffic, a division of 3i Innovation, had its iiiLEVEL road marking installed last year in the Terrace Tunnel, the busiest in the New Zealand city of Wellington. The inductively powered system comprises flush-mounted iiiLEVEL road markers, with uni-/bi-directional light direction and red and white LEDs. The intelligent iiiLEVEL road markers are said to provide dimming functions for day and night time adaption as well as emergency functions with all sides (light directions) on.

A previous Terrace Tunnel operator-led upgrade in 2001 had seen the introduction of white SMARTSTUD road marking to create a second lane to separate traffic. Five years earlier, the world’s first inductively powered LED road marker system had been successfully installed in the Tunnel.

Among the advantages of inductive powered road marking, claims 3i Traffic, is its speed of installation, low maintenance, fast identification of faults, and low power consumption. It is also not said to suffer from corrosion, is waterproof, impervious to chemicals and debris, and is non-sparking, increasing its safety value.

The B6 highway in Bremen, Germany has also seen a recent installation of 3i Traffic’s flush-mounted iiiLEVEL LED road marking. iiiLEVEL marking is said to have been introduced by the road’s authority to increase motorists’ visibility of lane closures for temporary and long term work zones.