Plans are moving forward for the construction of the Hangzhou Genshan East Road Crossing River Tunnel in China. The TBM that will be used for the project has been constructed by Chinese firm CRCHI and features a 15.01m diameter slurry cutting shield. Measuring 130m in length, the TBM weighs around 4,300tonnes, has an installed power of 9,755kW and a rated torque of 42,784Nm.

The Hangzhou Genshan East Road Crossing River Tunnel will be located in Hangzhou City, Zhejiang Province, China. The Genshan East Road Crossing Tunnel Project in Hangzhou will be an urban expressway, including the tunnel stretch. In addition the project includes building a comprehensive pipeline gallery, a ground connection line project and auxiliary works.

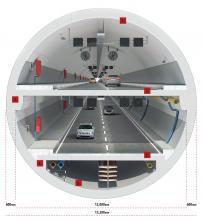

The total length of the project is 4,725m, including the access roads. Meanwhile, the tunnel measures 4,575m. A 3,160m stretch of the tunnel will be driven using the TBM. Around 2.3km of the tunnel will run directly underneath the Qiantang River.

The tunnel will feature twin tubes and allow traffic speeds of up to 80km/h.

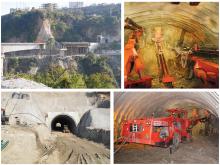

The project faces challenges as the TBM will pass through soft soil layers, reaching a maximum depth of 44.2m. As the tunnel section will feature a diameter of 15.01m, the stability of the tunnel face will be difficult to control. However the engineering team believe that using the TBM will help to control the stability of the tunnel face to prevent collapse.

While advancing in soft soil, the poor stratum bearing capacity and poor permeability is expected to cause the TBM to sink, and the segments to float up. To avoid problems from these effects on the TBM, precision attitude control of the TBM will be crucial, as will high quality of segment box culvert assembly. Due to the high content of viscous particles in the ground formation, a high capacity ground slurry treatment system is required. The TBM has been designed to prevent mud cakes forming on the cutterhead.

Given the length of the tunnel drive, the reliability of the TBM will be crucial. CRCHI says that the TBM has been designed with a particular focus on the reliability of the main drive seal and tailskin seal, as well as for ensuring high wear resistance of the cutterhead, cutters, and slurry pipelines.

Because there may be harmful gases in the formation, the TBM has been installed with reliable harmful gas detection devices and a high-power ventilation system.

The CRCHI R&D department has tackled the key problems. The machine was designed to have soft soil cutterhead which features cutter change in free air, frequency conversion motor for the main drive and retractable cutterhead. Cutting-edge technology include a main drive seal that is automatically pressurised, high precision gas-liquid pressure balance control and simultaneous lifting and assembly of segments and box culverts. The firm claims that this latest unit will offer an increase in performance and reliability, as well as adaptability to challenging geological conditions.

The work for the project is being carried out by the China Railway 14th Bureau.